A directional bridge based on three-dimensional assembly and its assembly process

A technology of three-dimensional assembly and assembly process, which is applied in the direction of circuits, measuring devices, electrical components, etc., can solve the problems of unsatisfactory high-frequency characteristics and insufficient ultra-broadband working ability, and achieve the improvement of directivity and high-frequency end working ability. Efficient tonality design and good adjustability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention is described in detail below in conjunction with accompanying drawing:

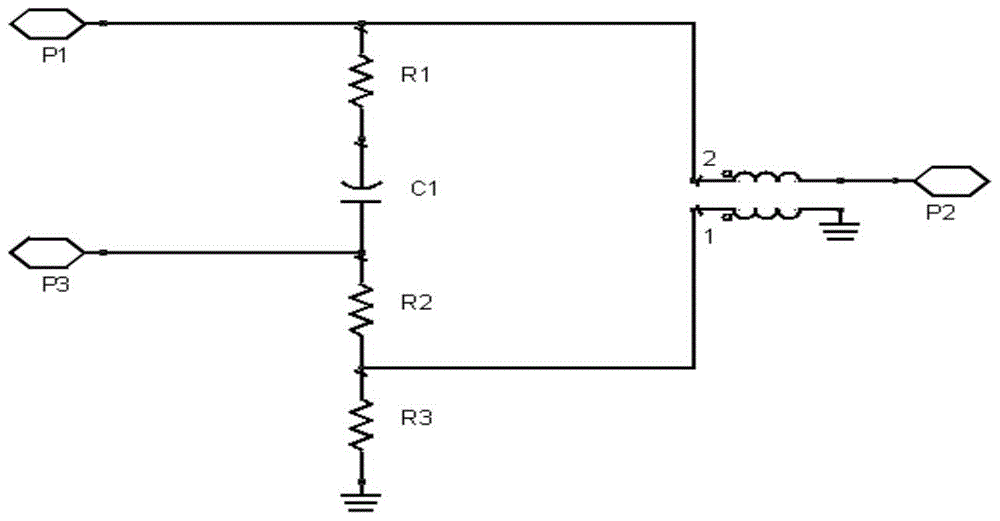

[0041] The invention is based on the directional bridge of the coaxial balun and the lumped parameter resistance power dividing circuit, figure 1 Shown is the schematic diagram of a combined directional bridge based on a coaxial balun and resistive power divider, P1 port 2 and P2 port 1 are through ports, and P3 port 3 is a coupling / isolation port. Resistors and capacitors form a resistive power dividing circuit. When the signal is transmitted in the forward direction, P1 port 2 is the input port. After the resistance power is divided, part of the power is coupled to the output of the P3 port, and part of the power is output directly through the P2 port 1; when the signal is transmitted in the reverse direction, Port 1 of P2 is the input port, and the signal is converted from unbalanced to balanced by the balun. The power dividing circuit cancels at P3 port 3, realizes signal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com