Submersible permanent magnet synchronous motor

A permanent magnet synchronous motor and submersible technology, which is applied to synchronous motors, magnetic circuits and electrical components with static armatures and rotating magnets. and other problems, to achieve the effect of improving assembly process, improving motor performance, and optimizing electromagnetic scheme

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

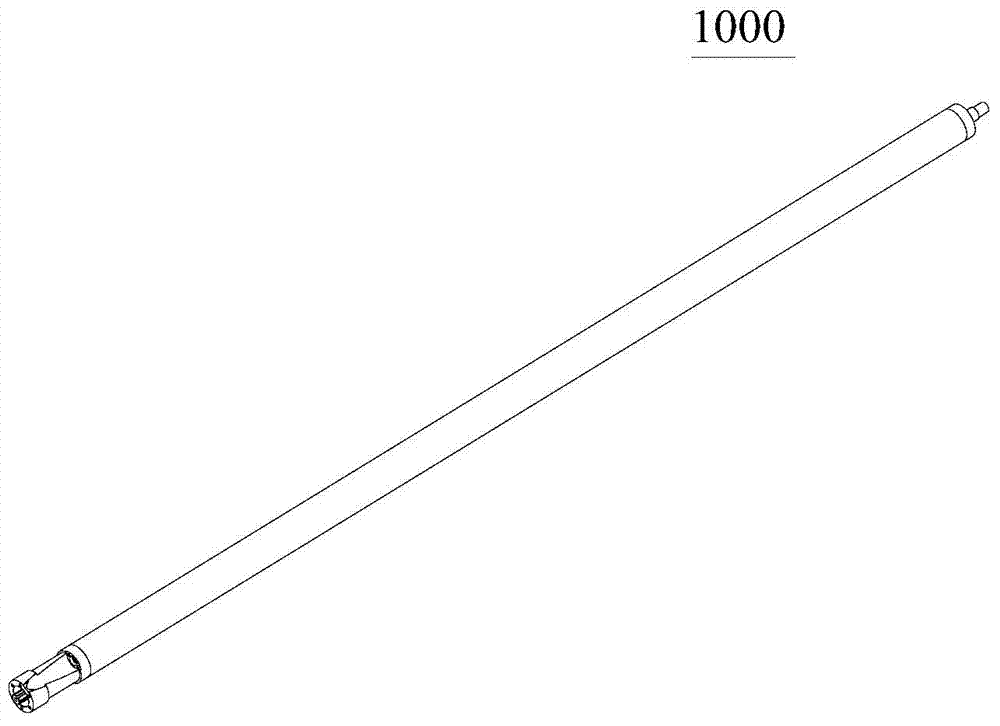

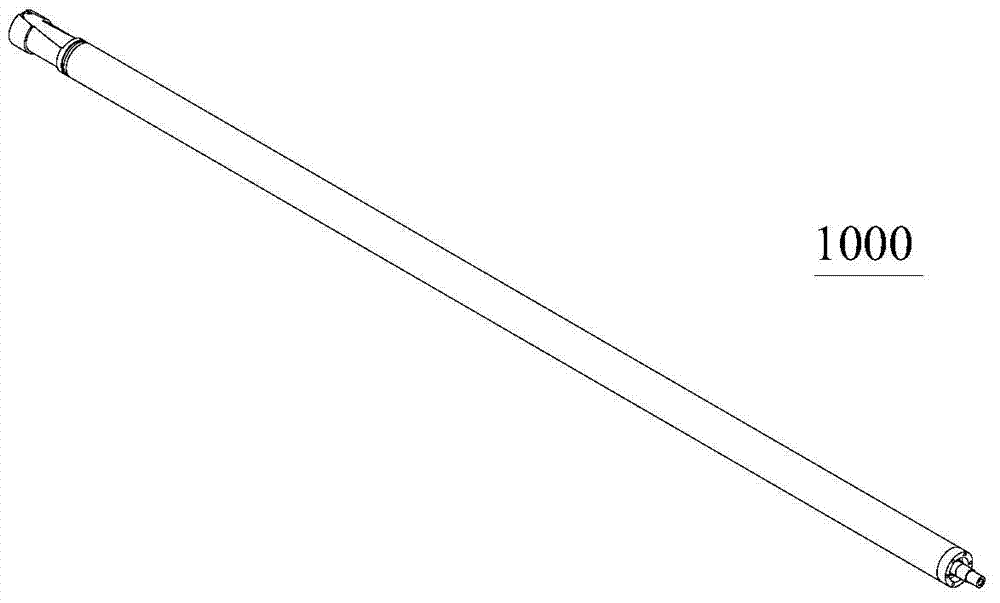

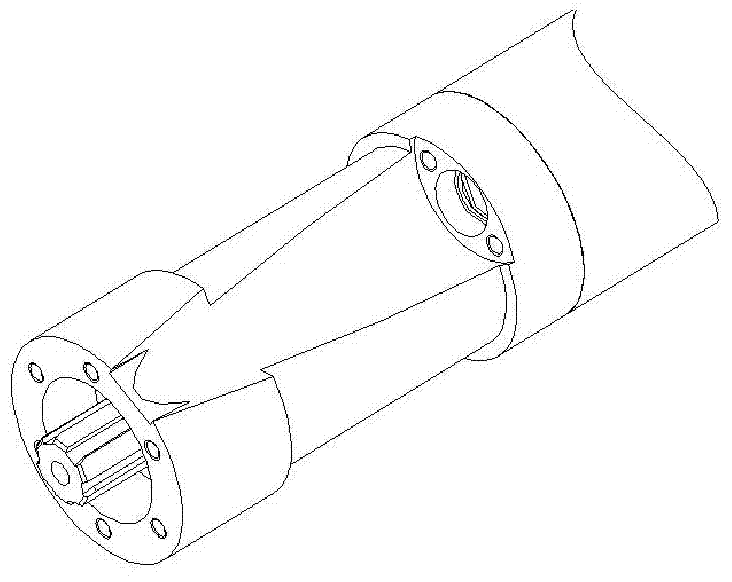

[0064] figure 1 It is one of the overall structural schematic diagrams of the oil submersible permanent magnet synchronous motor of the present invention. figure 2 It is the second schematic diagram of the overall structure of the oil submersible permanent magnet synchronous motor of the present invention. Figure 3a for figure 1 The enlarged view of the output end of the medium submersible permanent magnet synchronous motor, Figure 3b for figure 2 Enlarged view of the tail end of the medium submersible permanent magnet synchronous motor. Figure 3a , Figure 3b The two ends of the submersible permanent magnet synchronous motor are shown respectively. Such as Figure 1 to Figure 3b As shown, the present invention provides a kind of oil submersible permanent magnet synchronous motor 1000, this oil submersible permanent magnet synchronous motor is a modular design, its two ends are respectively provided with connecting devices, and one end is an output end connecting he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com