Process for concentrating aqueous hydrogen halide solutions

A hydrogen halide and solution technology, applied in chemical instruments and methods, chlorine/hydrogen chloride, chlorine/hydrogen chloride purification, etc., can solve problems such as equipment failure, unexpected crystallization of extractant, blockage of evaporation device, etc., and achieve high usable energy The effect of content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

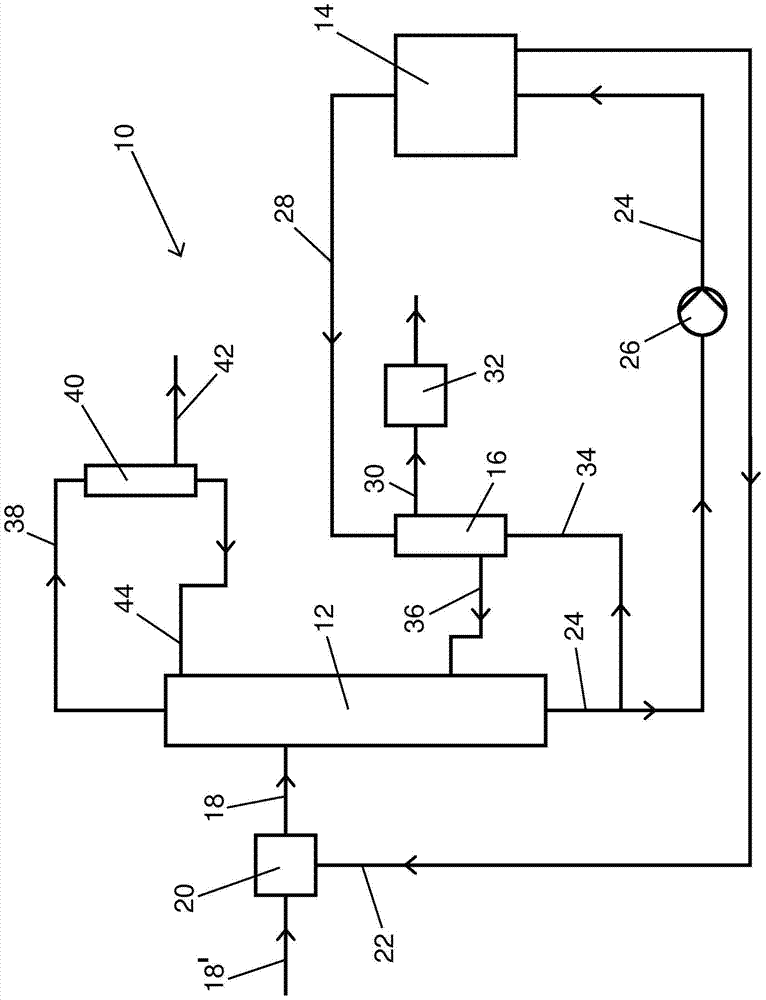

[0076] The apparatus 10 for concentrating an aqueous starting solution of hydrogen halide shown in the drawing comprises: a distillation unit 12 designed as a rectification column 12, an evaporation unit 14 and a heat exchanger for heating the bottom product of the rectification column 12 16.

[0077] A feed line 18 for an aqueous hydrogen halide solution containing an extractant opens into the upper part of the rectification column 12, said solution being pre-generated in the mixing device 20 via feed line 18' into The hydrogen halide aqueous starting solution of the mixing device 20 is mixed with the concentrated extractant-containing aqueous solution from the evaporation device 14 and fed to the mixing device 20 via the return line 22 .

[0078] On the lower part or bottom of the rectification column 12 there is provided a removal line 24 for the solution containing the extractant, said line being provided with a pump 26 and fed into the evaporation device 14 . On the one ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com