Susceptor for epitaxial growing and method for epitaxial growing

A technology of epitaxial growth and susceptor, applied in chemical instruments and methods, crystal growth, single crystal growth, etc., can solve problems such as wafer quality deterioration, achieve quality and yield improvement, and achieve the effect of uniform epitaxial layer thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

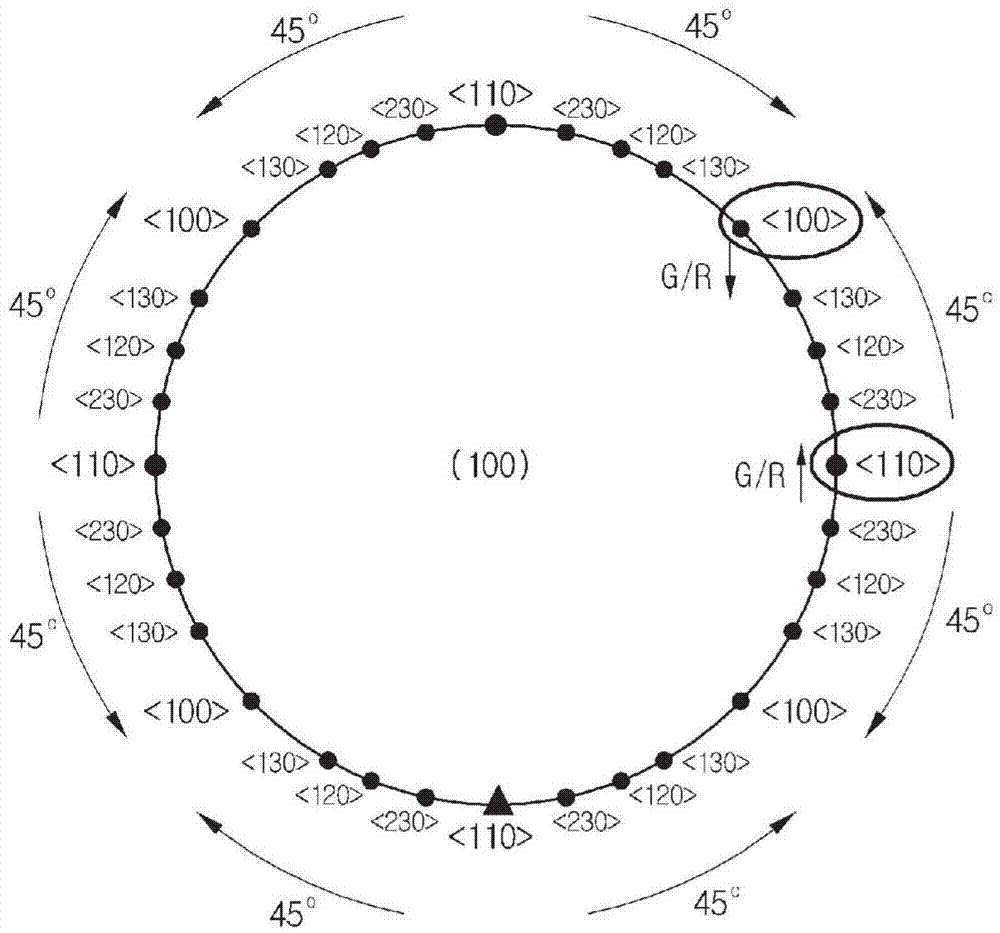

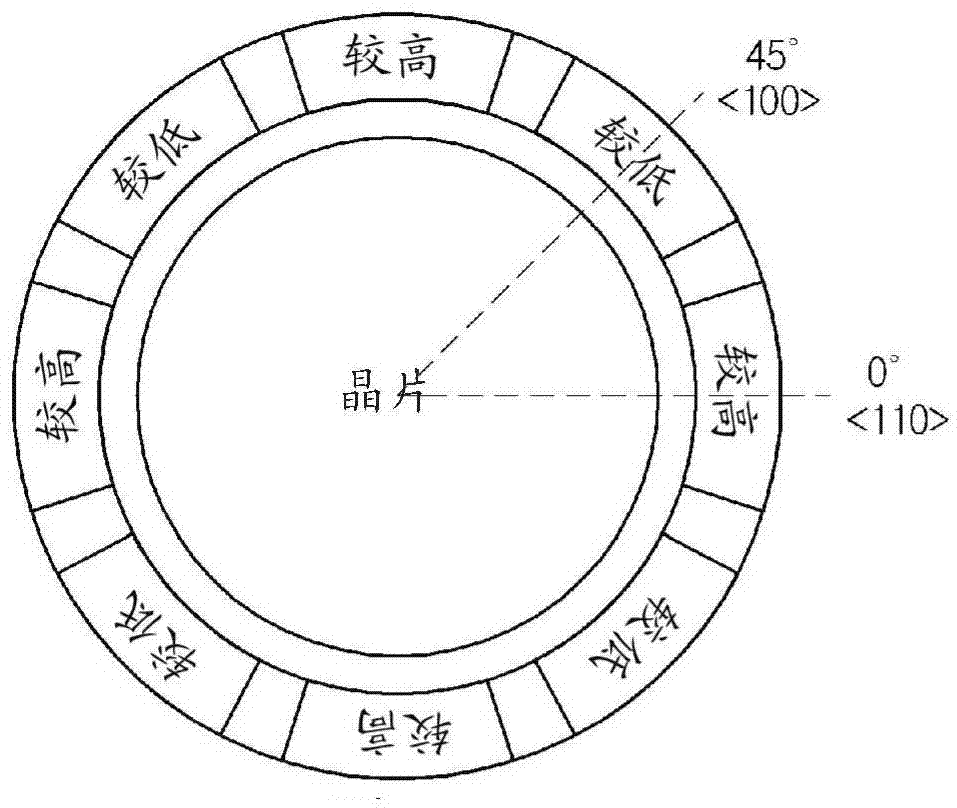

[0060] Described below is an embodiment in which a higher region on which the first gas regulating member is formed and a lower region on which the second gas regulating member is formed are asymmetrically formed with respect to the buffer region.

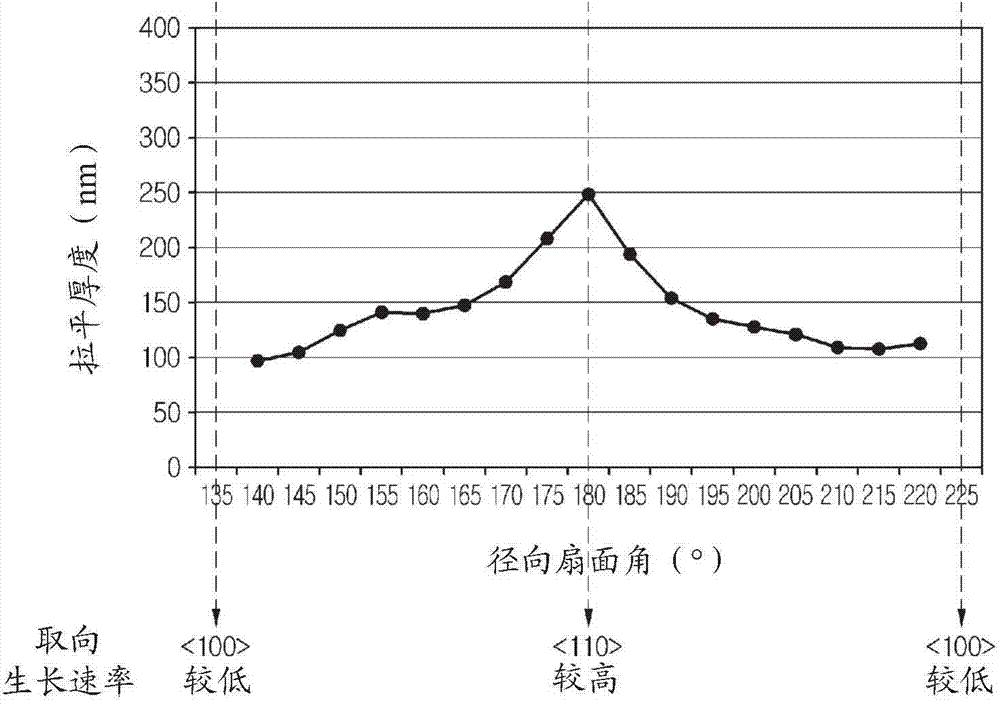

[0061] Figure 9 is a schematic diagram showing the region where the gas regulating member is formed on the susceptor according to Comparative Example 2, and Figure 10 is a simplified diagram showing a region where a gas regulating member is formed on a susceptor according to an embodiment. will refer to Figure 9 and Figure 10 Embodiments are described.

[0062] Figure 9 The thicknesses of certain regions of the wafer on the Comparative Example 2 susceptor are shown, more specifically, regions corresponding to angles between about 135 degrees and about 225 degrees as shown in FIG. 8 . From Figure 9 It can be understood that the thickness of the edge portion of the wafer is greatest at the center of the higher region of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com