Making method of zero-added acorn shell pigment ice cream

A production method and acorn shell technology, applied in the field of ice cream production, can solve the problems of single color, easy melting, low expansion rate of ice cream, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

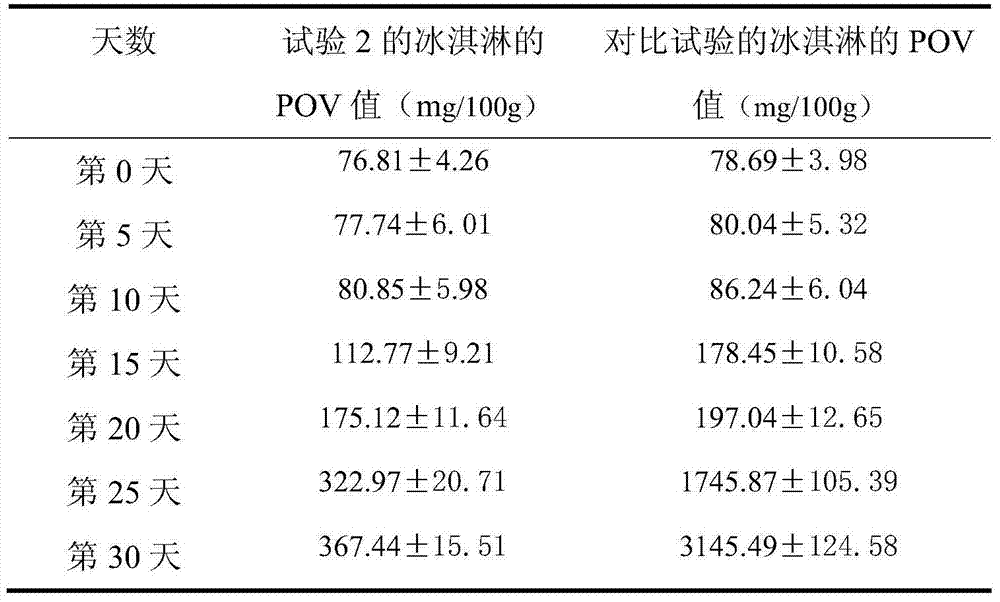

Examples

specific Embodiment approach 1

[0013] Specific embodiment one: the preparation method of the zero-added acorn shell pigment ice cream of the present embodiment is carried out according to the following steps:

[0014] 1. Beat the butter, then add the egg yolks in batches, stir well to get the butter and egg yolk mixture, set aside.

[0015] 2. Heat the milk in a water bath, add starch, stir and gelatinize, and cool to 5-10°C to obtain a milk-starch mixture;

[0016] 3. Mix the butter egg yolk mixture liquid in step 1 and the milk starch mixture liquid in step 2 to obtain ice cream liquid, stir and sterilize, cool, add acorn shell pigment, mix, and age.

[0017] 4. Pour the ice cream liquid in step 3 into the ice cream machine to thaw and freeze to obtain the finished acorn shell pigment ice cream.

specific Embodiment approach 2

[0018] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that each 100g of ice cream contains the following raw materials by mass percentage: 70-85% of milk, 2-4% of starch, 6-8% of butter, and 4.5% of egg yolk. ~6.5%, white granulated sugar 5.5~7.5%, acorn shell pigment 0.05~1.5%. Others are the same as the first embodiment.

specific Embodiment approach 3

[0019] Specific embodiment 3: The difference between this embodiment and specific embodiment 1 or 2 is that in step 1, white sugar must be added to the butter before it can be sent. Melt, add white granulated sugar to the butter, stir with a mixer at a speed of 5000-10000 rpm for 3-10 minutes to obtain whipped butter. Others are the same as the specific embodiment 1 or mode 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com