Preparation process for lithium aluminum hydride-tetrahydrofuran solution

A technology of lithium aluminum hydride and tetrahydrofuran, which can be applied to various metal hydrides, dissolution, dissolution and other directions, can solve problems such as explosive decomposition, and achieve the effect of safe use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-12

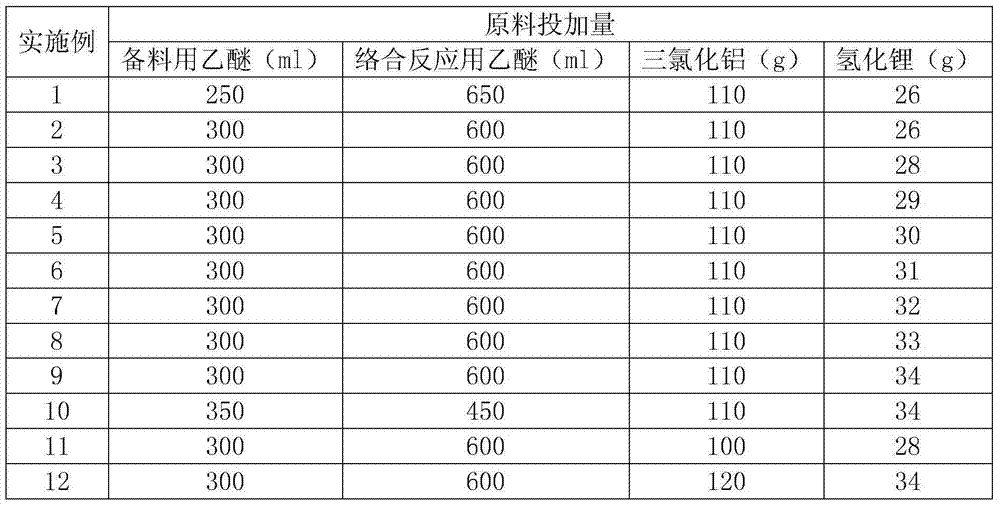

[0026] 1. Weigh each raw material according to the amount in Table 1;

[0027] The dosage of each raw material in the embodiment 1-12 of table 1

[0028]

[0029] Two, prepare lithium aluminum hydride-tetrahydrofuran solution according to the following steps:

[0030] (1) Material preparation

[0031] 1. Grind block lithium hydride in a ball mill to below 100 mesh, and set aside;

[0032] 2. Add aluminum trichloride to ether several times in an ice-water bath to make an ether solution of aluminum trichloride;

[0033] (2) Complexation reaction

[0034] In a 1000ml three-necked flask, install stirring, a constant pressure funnel and a straight condenser, add diethyl ether, add lithium hydride, start stirring and raise the temperature to 28°C with an electric heating mantle, slowly drop the aluminum trichloride diethyl ether solution from the constant pressure funnel Add it to the ether solution of lithium hydride, and the dropping time is about 6-10 hours. The dropping p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com