Automatic printing device for bamboo chopsticks and method thereof

A technology of automatic printing and bamboo chopsticks, applied in printing, printing machines, rotary printing machines, etc., can solve the problems of product quality, efficiency, cost, equipment reliability, durability, degree of automation, and cannot meet the needs of high-quality bamboo products. Production needs, endangering personal safety and other issues, to achieve the effect of promoting product balance, improving labor productivity, and reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

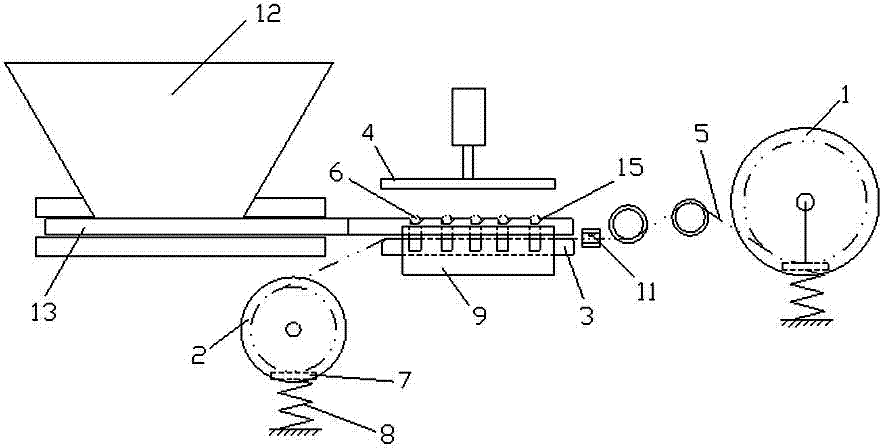

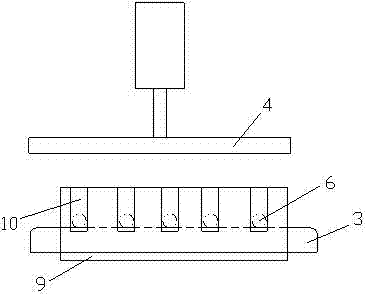

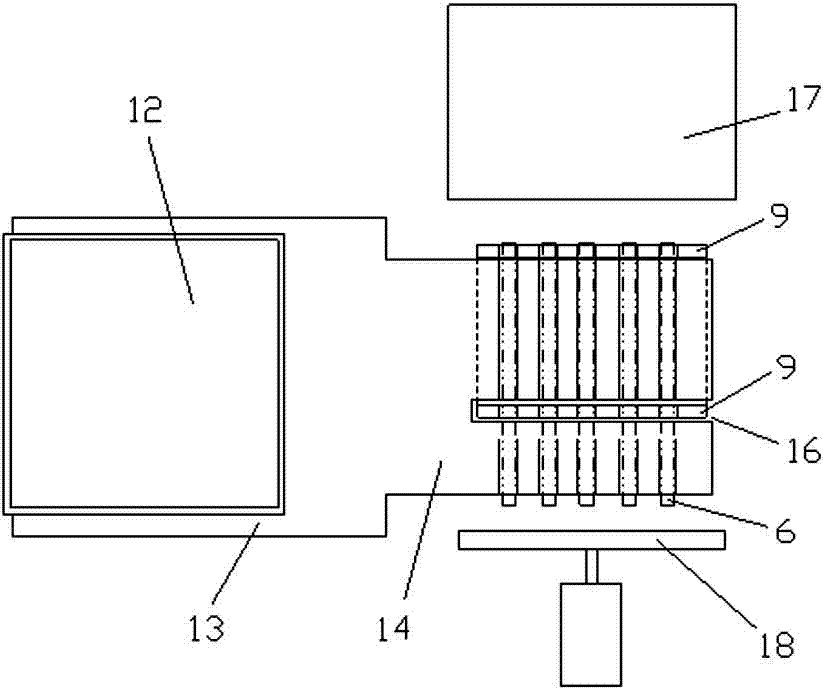

[0029] Such as Figure 1~3 As shown, a bamboo chopsticks automatic printing device includes a label reel 1 for label 5 unwinding and a base paper reel 2 for label 5 base paper winding, and also includes driving the base paper reel 2 to rotate to collect The driving device of the roll bottom paper 8 also includes a labeling mechanism positioned between the label reel 1 and the bottom paper reel 2, and the left side of the labeling mechanism is provided with a bamboo chopsticks material conveying mechanism; The base plate 3 that the bottom surface of the base paper is attached to and the pressing plate 4 that is positioned at the top of the base plate and can move up and down, the front and rear sides of the base plate 3 are respectively provided with a positioning bamboo chopsticks 6 and a limit plate 9 that can move up and down. The position plate 9 is provided with front and rear corresponding limit grooves 10 for limiting the bamboo chopsticks 6, and the height of the bottom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com