(Ba<x>Ca<1-x>)(Ti<y>M<1-y>)O3 system piezoelectric ceramic material and preparation method thereof

A technology of piezoelectric ceramics and ceramic materials, applied in the field of piezoelectric ceramic materials, can solve problems affecting material properties, difficulty in mixing, and affecting the chemical and structural uniformity of ceramic materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] This example provides a (Ba x Ca 1-x )(Ti y m 1-y )O 3 System piezoelectric ceramic material, its composition is represented by the following formula: (Ba 0.85 Ca 0.15 )(Ti 0.9 Zr 0.1 )O 3 , where M is Zr, the value of x is 0.85, and the value of y is 0.90.

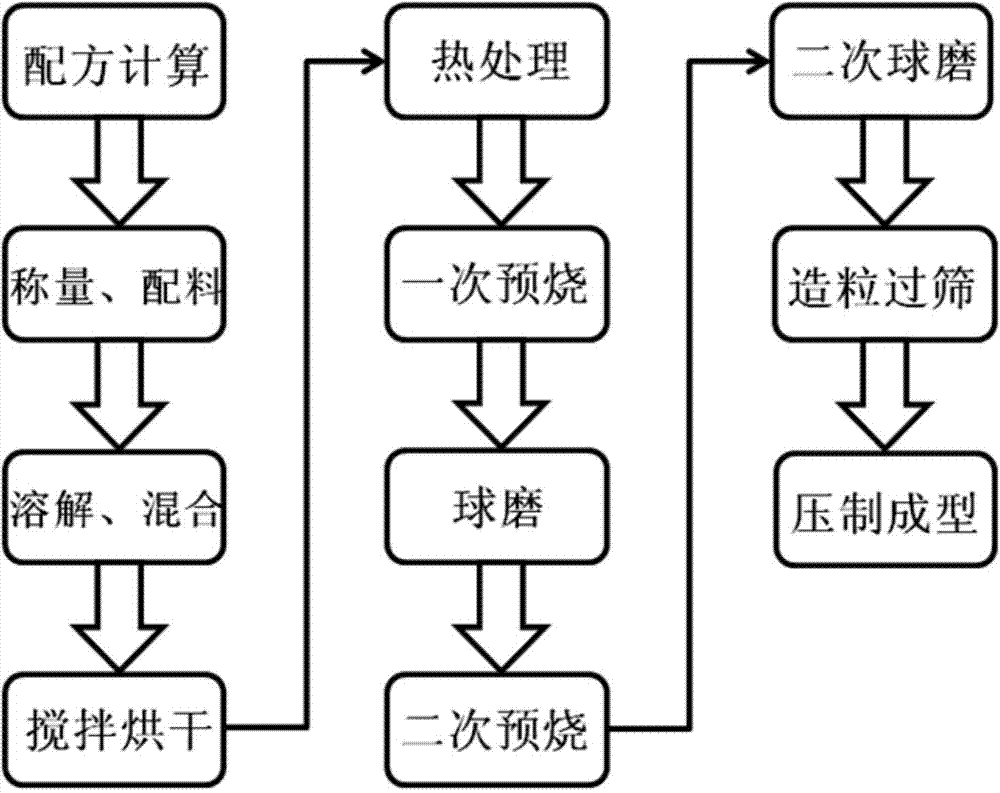

[0032] In this example (Ba x Ca 1-x )(Ti y m 1-y )O 3 The preparation method of system piezoelectric ceramic material, see figure 1 ,Specific steps are as follows:

[0033] Step 1: Ba(CH) with analytical purity of more than 98% 3 COO) 2 , Ca(CH 3 COO) 2 、TiO 2 and ZrO 2 As a raw material, according to the general formula (Ba 0.85 Ca 0.15 )(Ti 0.9 Zr 0.1 )O 3 The stoichiometric ratio is accurately calculated and accurately weighed.

[0034] Step 2: the weighed Ba(CH 3 COO) 2 and Ca(CH 3 COO) 2 Prepare a clear solution in a beaker and then mix, stir to keep it clear; add TiO to the clear solution in turn 2 , ZrO 2 , Citric acid monohydrate.

[0035] Step 3: Place the mixed solution on...

Embodiment 2

[0057] This example provides a (Ba x Ca 1-x )(Ti y m 1-y )O 3 System piezoelectric ceramic material, its composition is represented by the following formula: (Ba 0.85 Ca 0.15 )(Ti 0.95 Zr 0.05 )O 3 , where M is Zr, the value of x is 0.85, and the value of y is 0.95.

[0058] In this example (Ba x Ca 1-x )(Ti y m 1-y )O 3 The preparation method of system piezoelectric ceramic material, see figure 1 ,Specific steps are as follows:

[0059] Step 1: Ba(CH) with analytical purity of more than 98% 3 COO) 2 , Ca(CH 3 COO) 2 、TiO 2 and ZrO 2 As a raw material, according to the general formula (Ba 0.85 Ca 0.15 )(Ti 0.95 Zr 0.05 )O 3 The stoichiometric ratio is accurately calculated and accurately weighed.

[0060] Step 2: the weighed Ba(CH 3 COO) 2 and Ca(CH 3 COO) 2 Prepare a clear solution in a beaker and then mix, stir to keep it clear; add TiO to the clear solution in turn 2 , ZrO 2 , Citric acid monohydrate.

[0061]Step 3: Place the mixed solution...

Embodiment 3

[0072] This example provides a (Ba x Ca 1-x )(Ti y m 1-y )O 3 System piezoelectric ceramic material, its composition is represented by the following formula: Ba(Ti 0.9 sn 0.1 )O 3 , where M is Sn, the value of x is 1, and the value of y is 0.9.

[0073] In this example (Ba x Ca 1-x )(Ti y m 1-y )O 3 The preparation method of system piezoelectric ceramic material, see figure 1 ,Specific steps are as follows:

[0074] Step 1: Ba(CH) with analytical purity of more than 98% 3 COO) 2 、TiO 2 and SnO 2 As a raw material, according to the general formula Ba(Ti 0.9 sn 0.1 )O 3 The stoichiometric ratio is accurately calculated and accurately weighed.

[0075] Step 2: the weighed Ba(CH 3 COO) 2 Prepare a clear solution in a beaker, and add TiO to the clear solution sequentially 2 , SnO 2 , Citric acid monohydrate.

[0076] Step 3: Place the mixed solution on a magnetic stirring table and heat and stir at a temperature of 80°C until the water is evaporated, then p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curie temperature | aaaaa | aaaaa |

| D33 | aaaaa | aaaaa |

| D33 | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com