Iron sand and preparation process thereof

A manufacturing process, iron sand technology, applied in the field of iron sand and its manufacturing process, can solve the problems of no way to recycle, difficult production and processing, pollution of the environment, etc., to achieve easy organization of large-scale production, save sandblasting costs, and reduce the environment pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

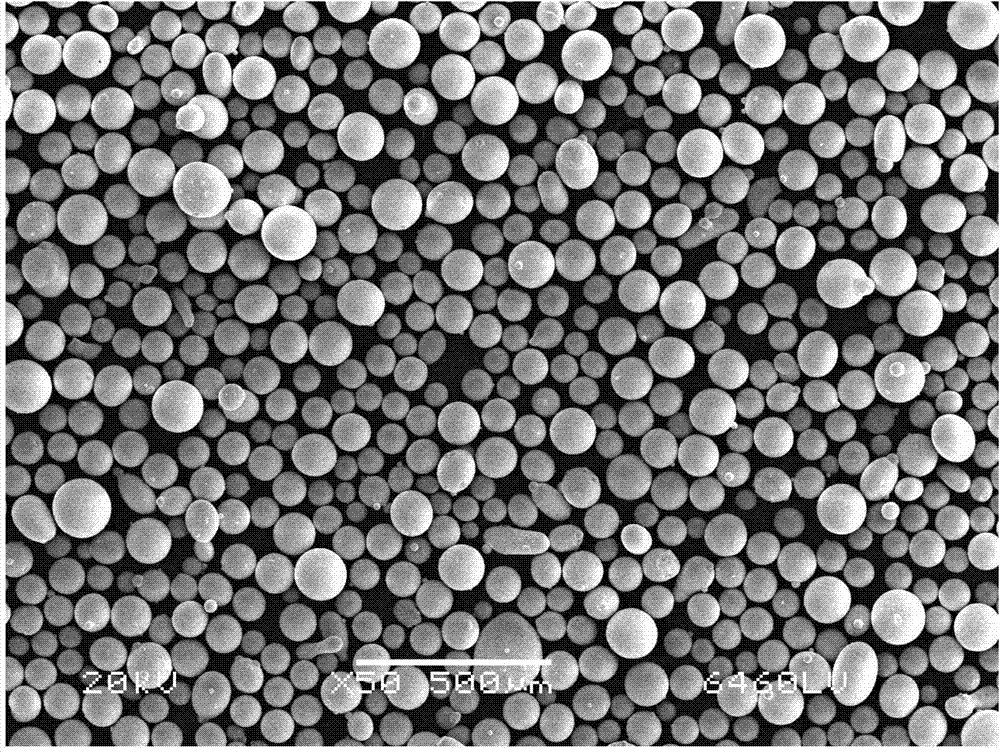

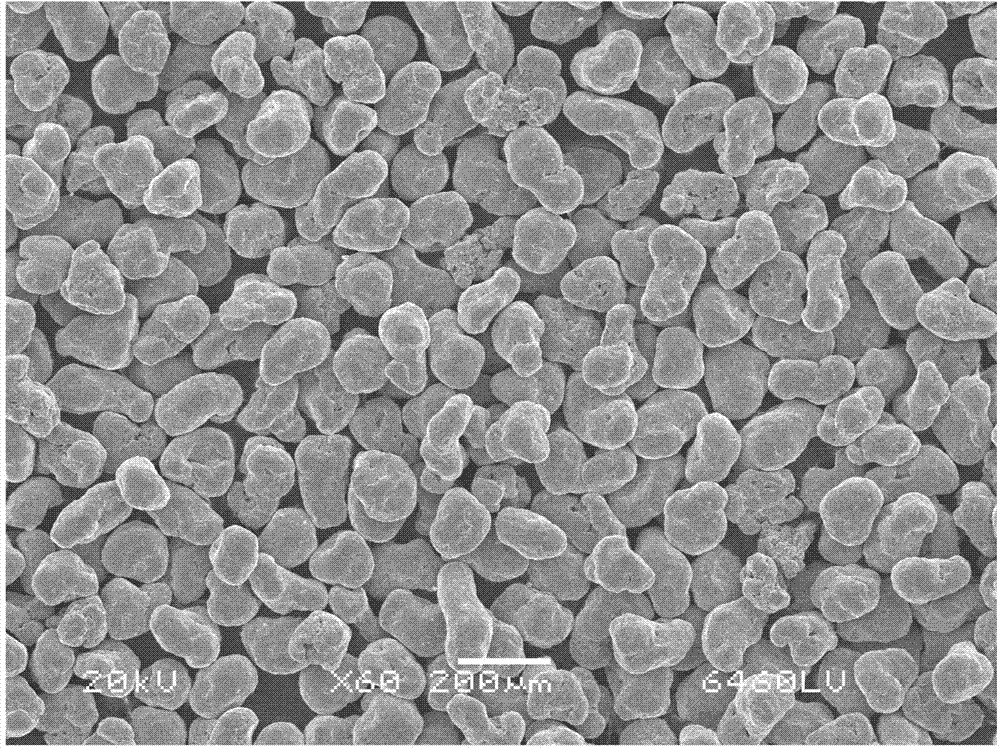

[0035] The particle size of the iron sand particles contained in the iron sand is greater than 0 μm and not greater than 125 μm. The particle size distribution of iron sand particles contained in iron sand is as follows: the weight ratio of iron sand particles with a particle size greater than 75 μm is 20%; the weight ratio of iron sand particles with a particle size not greater than 75 μm and greater than 50 μm is 40%; The weight ratio is 30%; the weight ratio of iron sand particles with a particle size not greater than 28 μm is 10%. The loose specific gravity of iron ore is not less than 3.5 g / cubic centimeter and not more than 4.9 g / cubic cm.

[0036] The manufacturing process of iron sand in the first embodiment includes a reduction step, an iron sand shaping step, an iron sand screening step, and an iron sand mixing step.

[0037] The reduction step is carried out before the iron sand shaping step, and is used for decarbonizing and deoxidizing the iron powder.

[0038] ...

no. 2 example

[0042] The particle size of the iron sand particles contained in the iron sand is greater than 0 μm and not greater than 125 μm. The particle size distribution of iron sand particles contained in iron sand is as follows: the weight ratio of iron sand particles with a particle size greater than 75 μm is 5%; the weight ratio of iron sand particles with a particle size not greater than 75 μm and greater than 50 μm is 50%; The weight ratio is 35%; the weight ratio of iron sand particles with a particle size not greater than 28 μm is 10%. The loose specific gravity of iron ore is not less than 3.5 g / cubic centimeter and not more than 4.9 g / cubic cm.

[0043] The iron sand manufacturing process of the second embodiment includes a reduction step, an iron sand shaping step, an iron sand screening step, and an iron sand mixing step.

[0044] The reduction step is carried out before the iron sand shaping step, and is used for decarbonizing and deoxidizing the iron powder.

[0045] In ...

no. 3 example

[0049] The particle size of the iron sand particles contained in the iron sand is greater than 0 μm and not greater than 125 μm. The particle size distribution of iron sand particles contained in iron sand is as follows: the weight ratio of iron sand particles with a particle size greater than 75 μm is 0; the weight ratio of iron sand particles with a particle size not greater than 75 μm and greater than 50 μm is 98%; The ratio is 1%; the weight ratio of iron sand particles with a particle size not greater than 28 μm is 1%. The loose specific gravity of iron ore is not less than 3.5 g / cubic centimeter and not more than 4.9 g / cubic cm.

[0050] The iron sand manufacturing process of the third embodiment includes a reduction step, an iron sand shaping step, an iron sand screening step, and an iron sand mixing step.

[0051] The reduction step is carried out before the iron sand shaping step, and is used for decarbonizing and deoxidizing the iron powder.

[0052] In the iron sa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com