Surface nanocrystallization manufacture method for improving oxidation resistance performance of heat resistant steel

An anti-oxidation, nano-technology, applied in the field of surface nano-ization, can solve the problems of unsatisfactory anti-oxidation performance, influence of workpiece size, accelerated material oxidation, etc. small damage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

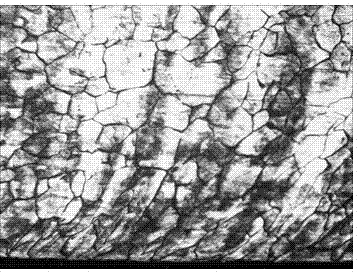

Image

Examples

Embodiment 1

[0027] Provided is a preparation method for improving the oxidation resistance of heat-resistant steel by surface nanometerization:

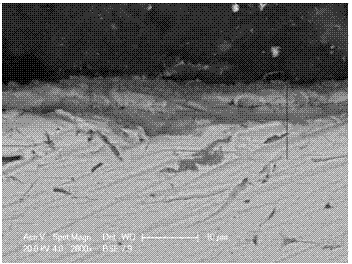

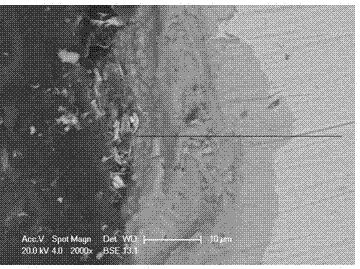

[0028] refer to Image 6 , using a four-column spinning machine to transmit pressure through hydraulic oil. The material of the rolling indenter is GCr15, the sample to be processed is a high-chromium austenitic heat-resistant steel Super304H, the grinding pressure is 10MPa, the size of the grinding sample is 60*60mm, the grinding time is 30min, and the grinding speed is 2rpm.

[0029] Before the surface is mechanically ground, the cylinder body on the pressure plate 3 is first cleaned and inspected, and then installed on the pressure plate 3 . Set the process parameters such as the speed of the final shaft of the four-column spinning machine, conduct trial grinding on the sample, and determine that the grinding position is in the middle of the plate. The plate was ground from No. 200 to No. 3000 with sandpaper, and then polished to a mirror s...

Embodiment 2

[0036] Provided is a preparation method for improving the oxidation resistance of heat-resistant steel by surface nanometerization:

[0037] refer to Image 6 , using a four-column spinning machine to transmit pressure through hydraulic oil. The material of the rolling indenter is GCr15, the sample to be processed is a high-chromium austenitic heat-resistant steel Super304H, the grinding pressure is 8MPa, the size of the grinding sample is 60*60mm, the grinding time is 30min, and the grinding speed is 2rpm.

[0038]Before the surface is mechanically ground, the roller cylinder on the pressure plate 3 is first cleaned and inspected, and installed on the pressure plate 3. Set the process parameters such as the final shaft speed of the four-column spinning machine, conduct trial grinding on the sample, and make sure that the grinding position is in the middle of the plate. The plate is polished from No. 200 to No. 3000 with sandpaper, and then polished to a mirror surface. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com