Vacuum thermal insulation house body used for ultralow temperature refrigeration house

A vacuum insulation and ultra-low temperature technology, which is applied in household refrigeration devices, applications, household appliances, etc., can solve the problems of condensation on the outer surface of the enclosure structure, increase the operating cost of the refrigeration system, and cannot produce the storage board. The thermal effect is obvious, the effect of solving condensation and bulky, and reducing mechanical damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

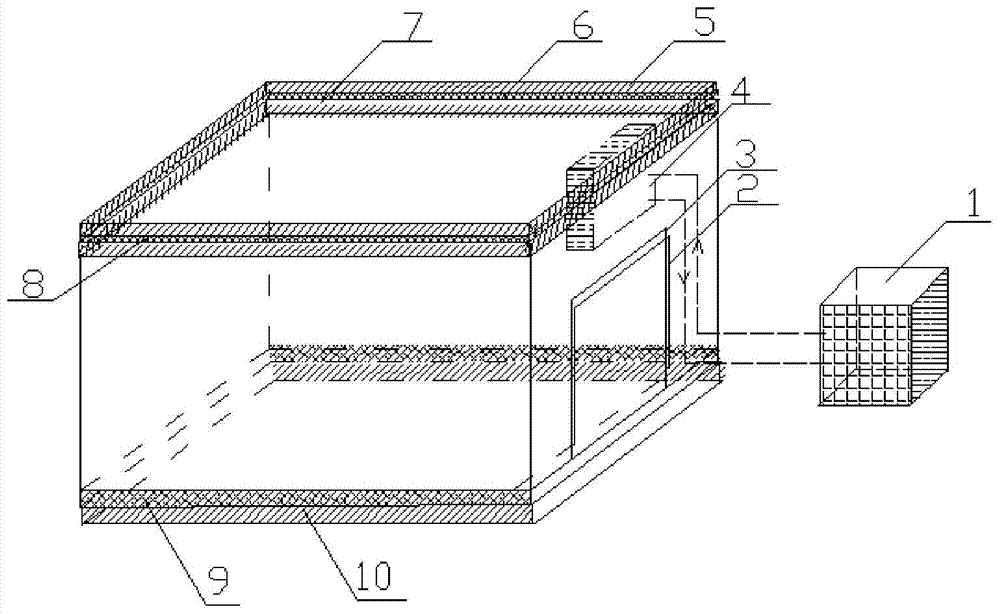

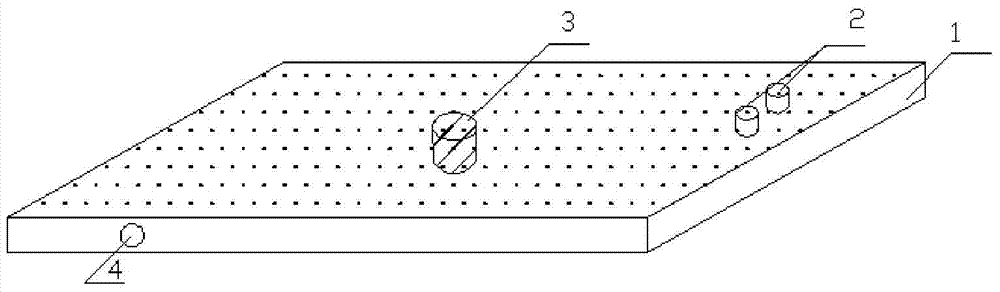

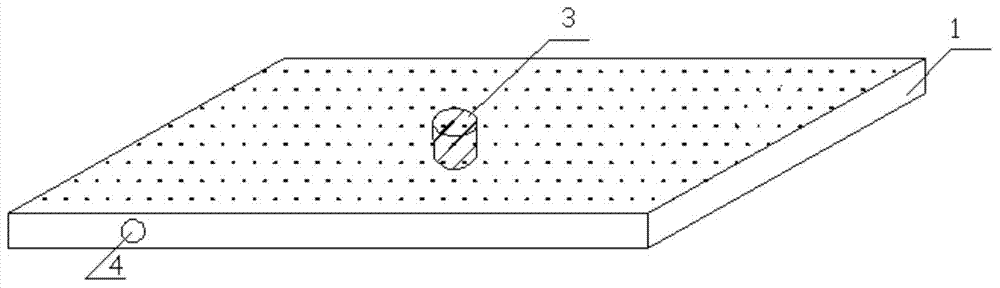

[0027] The schematic diagram of the vacuum heat insulation storage body used in the ultra-low temperature cold storage of the present invention is as follows figure 1 As shown, it consists of enclosure, top shelf and bottom shelf. The enclosure is made up of a front wall storage panel, a left enclosure storage panel, a right enclosure storage panel and a rear enclosure storage panel, and a storage door is installed on the front wall storage panel. The structure of the front panel, the left panel, the right panel and the rear panel is the same as that of the top panel, except that an evaporator installation hole is added on the top panel. The front panel, the left panel, the right panel, the rear panel and the top panel are respectively composed of an inner rigid polyurethane board 7, a middle stainless steel vacuum layer 6 and an out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com