Safety injection integrated system

A complete system and safe injection technology, applied in reactors, greenhouse gas reduction, nuclear engineering, etc., can solve the problems of increased equipment costs, large number of equipment, complex structures, etc., to reduce construction costs, operation and maintenance costs, and maintenance difficulties Reduce, reduce the effect of equipment purchase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

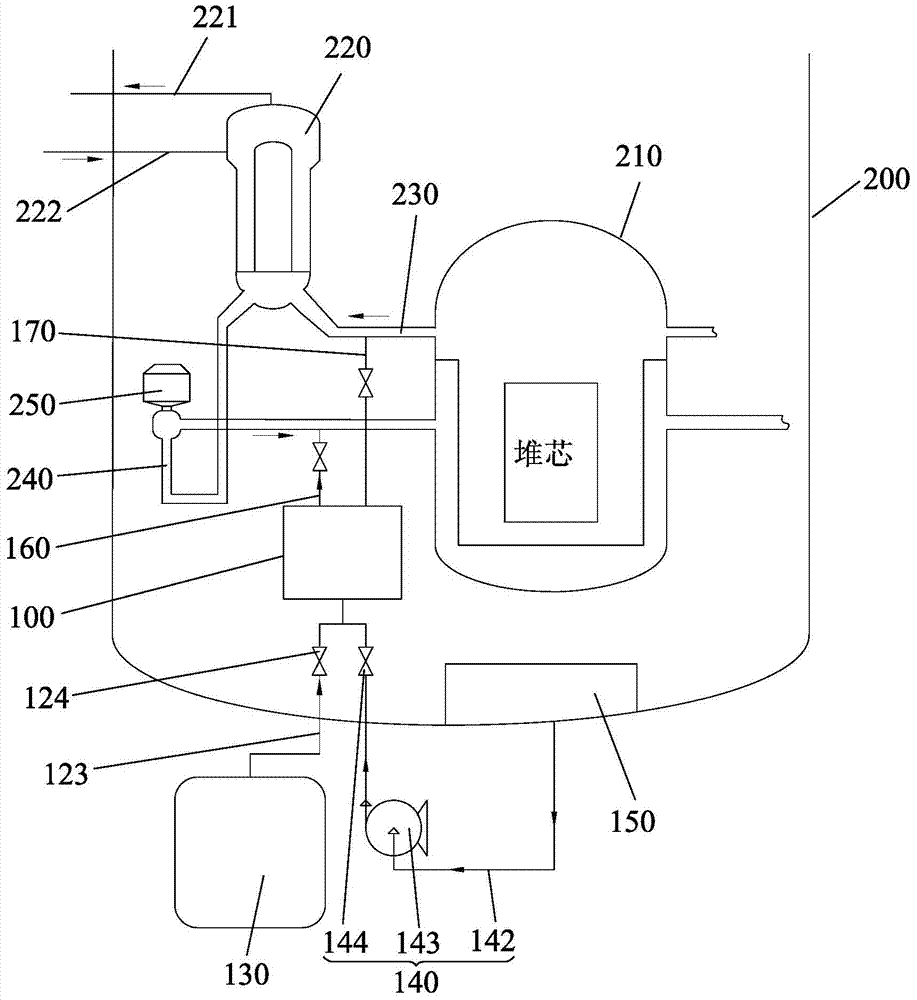

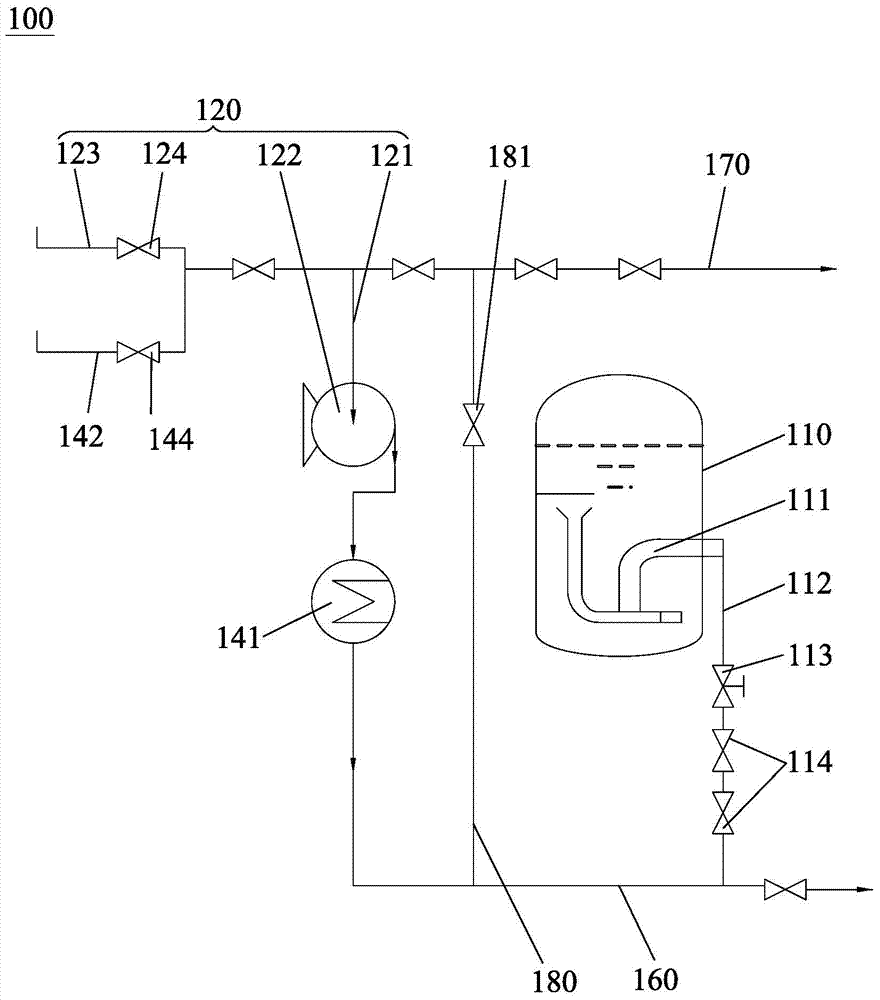

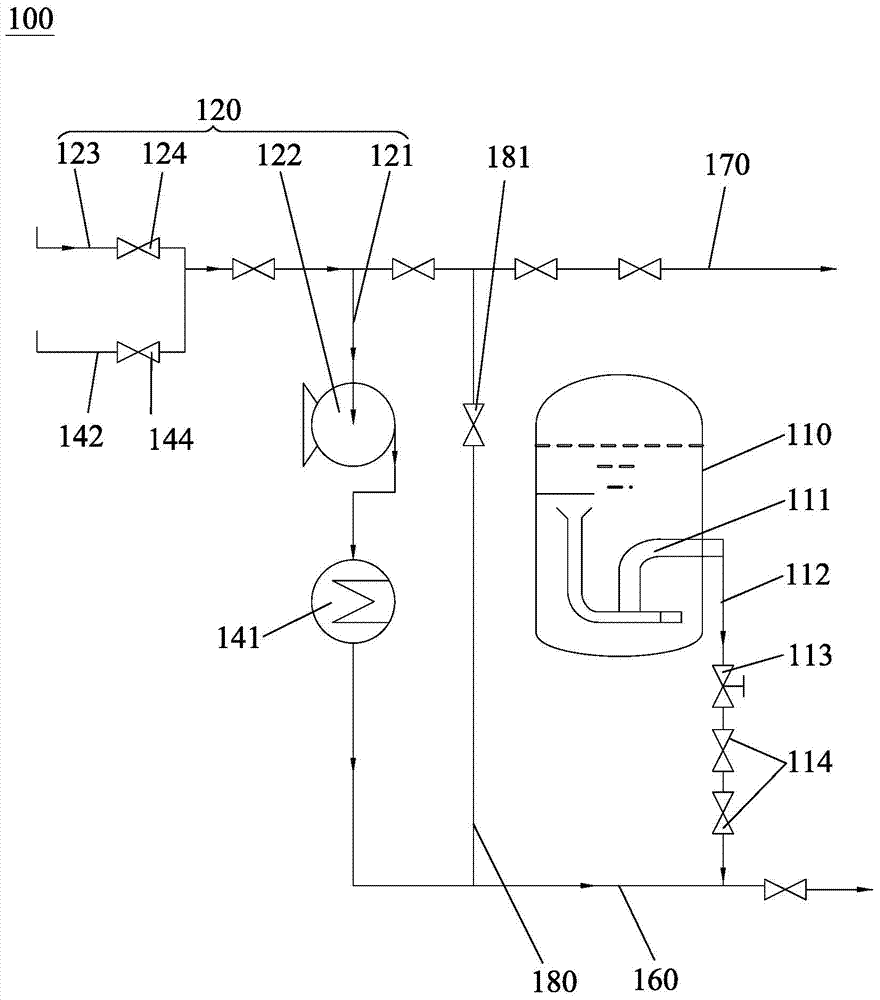

[0028] Embodiments of the present invention will now be described with reference to the drawings, in which like reference numerals represent like elements. The safety injection complete system 100 provided by the present invention is applicable to a pressurized water reactor nuclear power plant, and is used for providing safety injection to a primary circuit.

[0029] Such as figure 1 As shown, the safety injection complete system 100 is connected to the primary circuit coolant system in the containment vessel 200 . Specifically, a connected reactor pressure vessel 210 and a steam generator 220 are arranged inside the containment vessel 200 , and a reactor core is inside the pressure vessel 210 . Generally speaking, a pressurized water reactor nuclear power plant is designed with two to four steam generators 220, and only one of them is shown in this embodiment, and the configuration of the other steam generators 220 is well known to those skilled in the art.

[0030] More s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com