L-shaped split type composite busbar

A composite busbar and split-type technology, applied in the direction of output power conversion device, electrical components, AC power input conversion to DC power output, etc., can solve problems such as damage, device overheating, IGBT out of control, etc., to improve reliability, Reduce loop inductance, facilitate repair and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

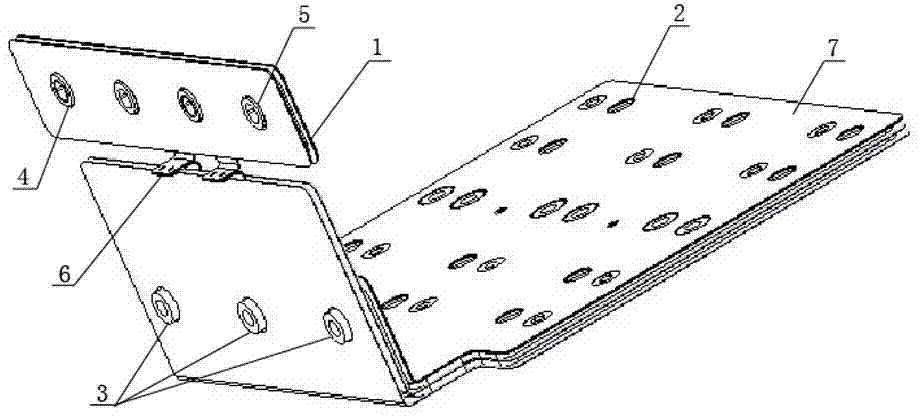

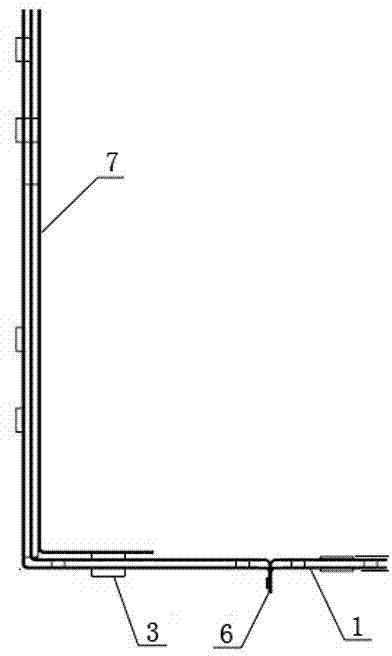

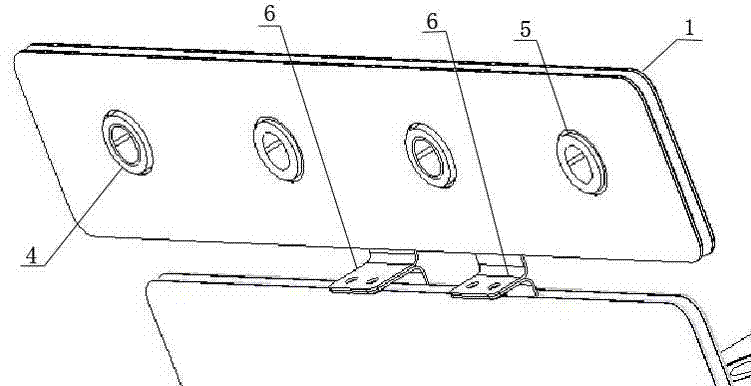

[0012] L-shaped split composite busbar, including the lower split composite busbar 7 composed of three layers of L-shaped busbars stacked in the same direction, the upper split composite busbar 1 composed of two layers of flat busbars stacked, and the adjacent busbars Insulating materials are filled between the rows, and the lower split composite busbar 7 is provided with an interface 2 for connecting circuit devices, and an AC output terminal 3 is drawn from one layer of the L-shaped busbar of the lower split composite busbar 7, One of the flat busbars of the upper split composite busbar 1 leads to the positive terminal 4 for inputting the forward DC voltage, and the other flat busbar of the upper split composite busbar 1 leads out to the output The negative terminal 5 of the negative DC voltage, the two-layer flat busbars of the upper split composite busbar 1 are respectively connected to the other two layers of L-shaped busbars of the lower split composite busbar 7 through l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com