Broad molecular weight distribution polypropylene resins

A technology of polypropylene resin and resin, which is applied in the field of polypropylene resin and products made from it, and can solve problems such as poor melt strength and unsuitable conversion process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0097] The external electron donors used in the preparation of the electron donor catalyst component may be those electron donors used in the preparation of the solid titanium catalyst component. In either embodiment, each external electron donor (A) and (B) comprises an organosilicon compound.

[0098] In either embodiment, the one or more external electron donors may include organosilicon compounds of the formula:

[0099] R 3 n Si(OR 4 ) 4-n

[0100] where R 3 and R 4 independently represent hydrocarbon groups and 0<n<4.

[0101] Examples of suitable organosilicon compounds include trimethylmethoxysilane, trimethylethoxysilane, dimethyldimethoxysilane, dimethyldimethoxysilane, dimethyldiethoxysilane , Diisopropyldiethoxysilane, tert-butylmethyl-n-diethoxysilane, tert-butylmethyldiethoxysilane, tert-amylmethyldiethoxysilane, diphenyldimethoxysilane , phenylmethyldimethoxysilane, diphenyldiethoxysilane, bis-o-tolyldimethoxysilane, bis-m-tolyldimethoxysilane, bis-p-to...

Embodiment approach

[0176] E1. Polypropylene resin, which comprises:

[0177] at least 50 mol% propylene;

[0178] MWD(Mw / Mn) is greater than 5;

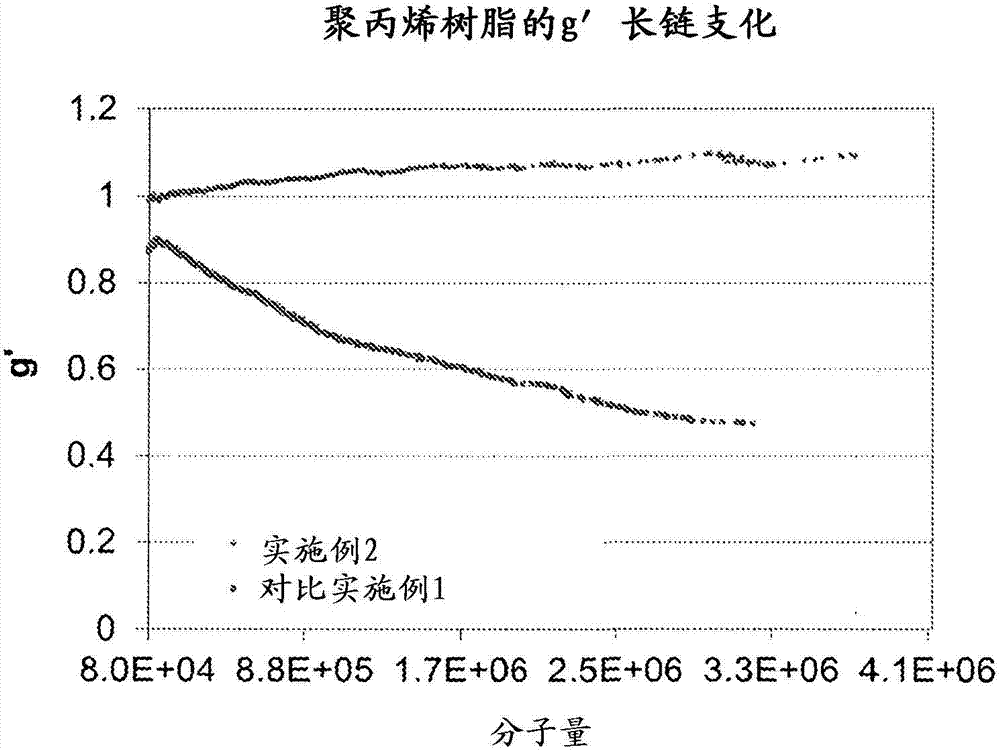

[0179] a branching index (g') of at least 0.95; and

[0180] Using an extensional rheometer, the melt strength measured at 190°C is greater than 20 cN.

[0181] E2. The resin of embodiment El wherein the MWD is 6-15.

[0182] E3. The resin of any one of the preceding embodiments, wherein the melt strength is from 50 cN to 200 cN.

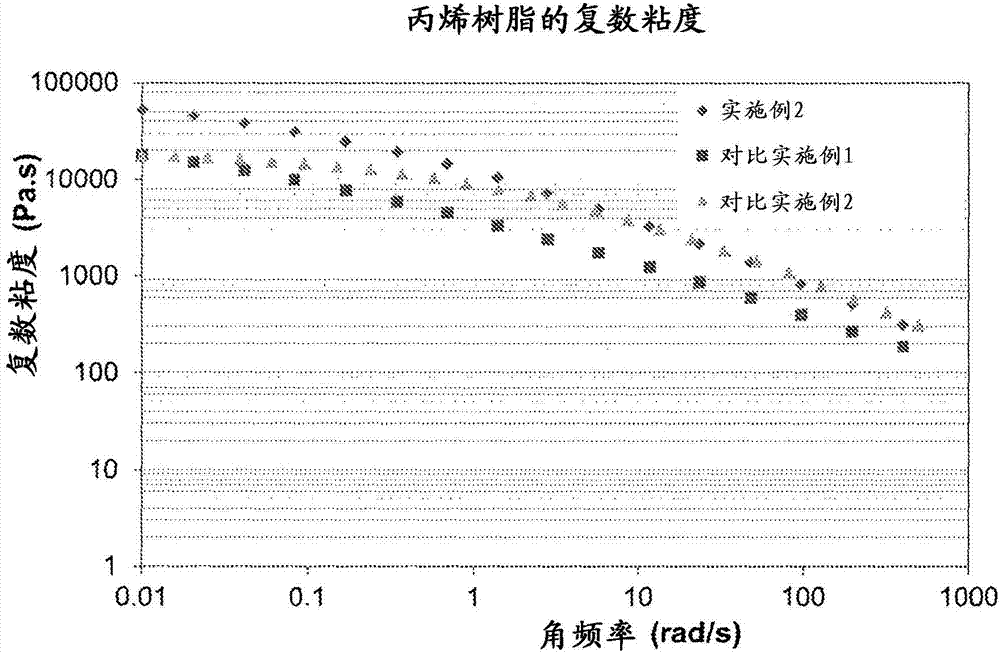

[0183] E4. The resin of any one of the preceding embodiments comprising a viscosity ratio of 35-80, as determined by the complex viscosity ratio at 190°C at an angular frequency of 0.01-100 rad / s, at a fixed strain of 10%.

[0184] E5. The resin of any one of the preceding embodiments, which has a heat distortion temperature of greater than or equal to 100°C, as measured in accordance with ASTM D648, using a load of 0.45 MPa (66 psi).

[0185] E6. The resin of any preceding embodiment, wherein the resin is an impact cop...

Embodiment

[0217] To measure physical properties, Table 1 and the following ASTM test methods described below were utilized.

[0218]

[0219] Melt Flow Rate (MFR): MFR is measured according to ASTM D1238, condition L, at 230°C and a load of 2.16 kg, using a melt index meter.

[0220] Flexural Modulus: Flexural modulus was measured using an Instron machine according to ASTM D790A using a crosshead speed of 1.27 mm / min (0.05 in / min) and a support span of 50.8 mm (2.0 in).

[0221]Tensile Strength: According to ASTM D638, using a crosshead speed of 50.8mm / min (2.0in / min), and a gauge length of 50.8mm (2.0in), using an Instron machine, measure the tensile strength at yield, yield elongation and elongation at break.

[0222] Notched Izod Impact Strength: The notched Izod impact strength was measured according to ASTM D256 at room temperature (21° C.) using equipment manufactured by Empire Technologies Inc.

[0223] Heat Distortion Temperature (HDT): HDT is measured according to ASTM D64...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt strength | aaaaa | aaaaa |

| melt strength | aaaaa | aaaaa |

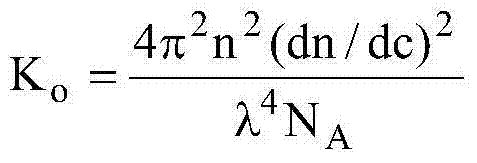

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap