High-melt-strength propylene/ethylene/butene copolymer and preparation method thereof

A high melt strength, butene copolymerization technology, used in the preparation of propylene/ethylene/butene ternary random copolymers, and the field of propylene/ethylene/butene random copolymers, can solve the problem that mechanical properties and processing cannot be obtained. Performance propylene polymers, inability to prepare supermolecules, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

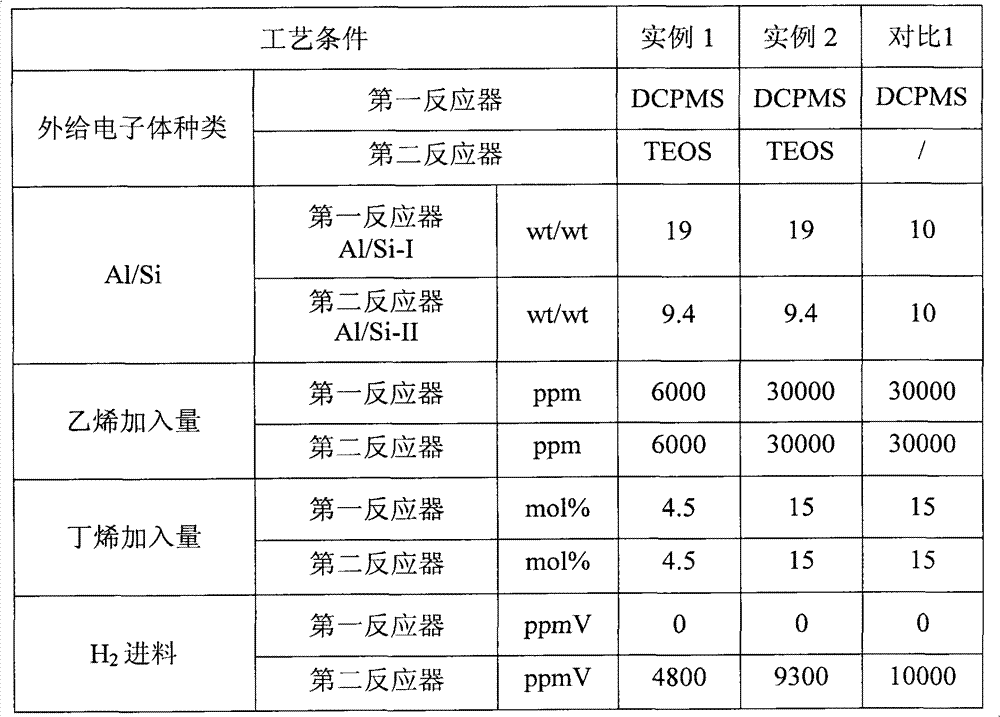

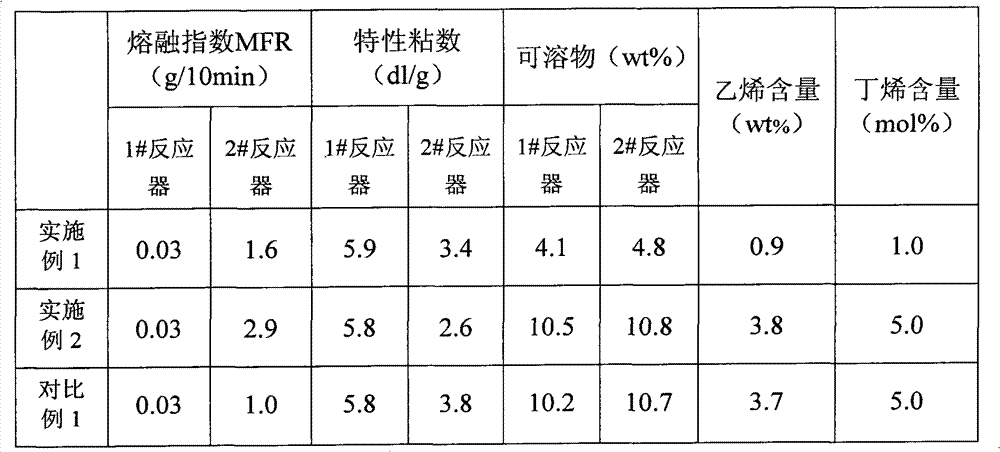

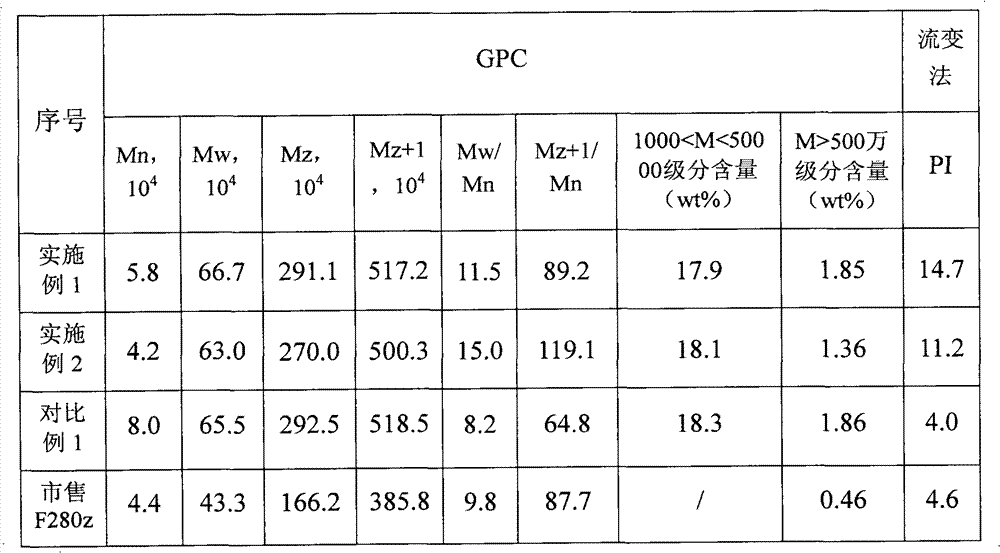

Embodiment 1

[0071] The polymerization reaction was carried out on a polypropylene pilot plant. Its main equipment includes prepolymerization reactor, first loop reactor and second loop reactor. Polymerization method and steps are as follows:

[0072] (1) Prepolymerization reaction:

[0073] The main catalyst (titanium-containing solid catalyst active component) is obtained by the method described in Example 1 of Chinese Patent CN93102795, its Ti content: 2.4wt%, Mg content 18.0wt%, di-n-butyl phthalate content: 13wt %.

[0074] The main catalyst, co-catalyst (triethylaluminum), and the first external electron donor (dicyclopentyldimethoxysilane, DCPMS) are pre-contacted at 10°C for 20 minutes, and then continuously added to the pre-polymerization reactor for pre-polymerization. In the polymerization reaction, the prepolymerization is carried out in the environment of the propylene liquid phase body, the temperature is 15° C., and the residence time is about 4 minutes. Under this condit...

Embodiment 2

[0083] With embodiment 1, just the ethylene addition in the first loop reactor becomes 30000ppm, and the butene addition becomes 15mol%; The ethylene addition in the second loop reactor becomes 30000ppm, and the butene addition is adjusted to 15mol%. At the same time, the amount of hydrogen in the second loop reactor was adjusted to 9300 ppmv.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com