High-rubber polypropylene polyphase copolymer resin used for 3D printing, and preparation method and application thereof

A technology of 3D printing and rubber content, applied in the field of polypropylene multiphase copolymer resin, can solve rare problems, achieve excellent performance, superior performance, and solve the effect of difficult processing and molding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

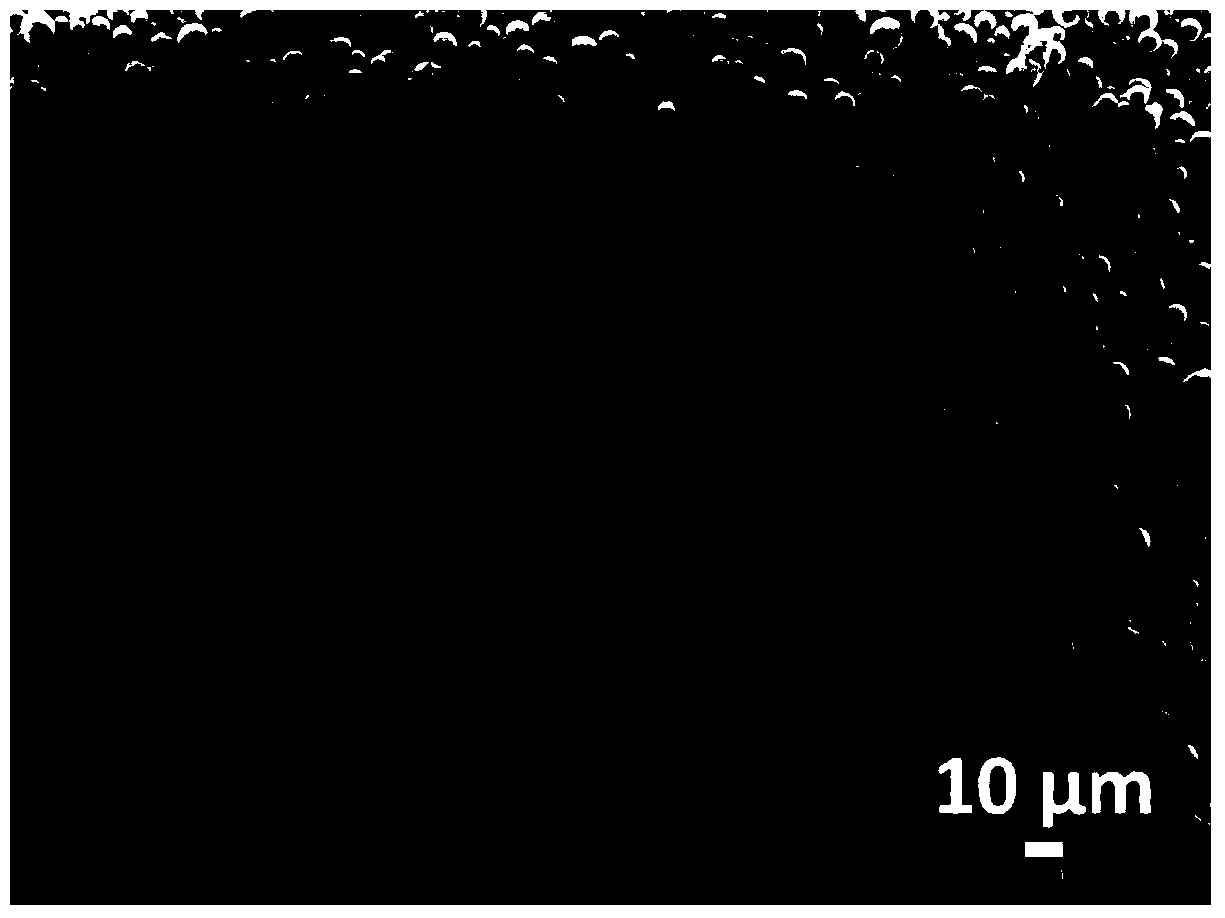

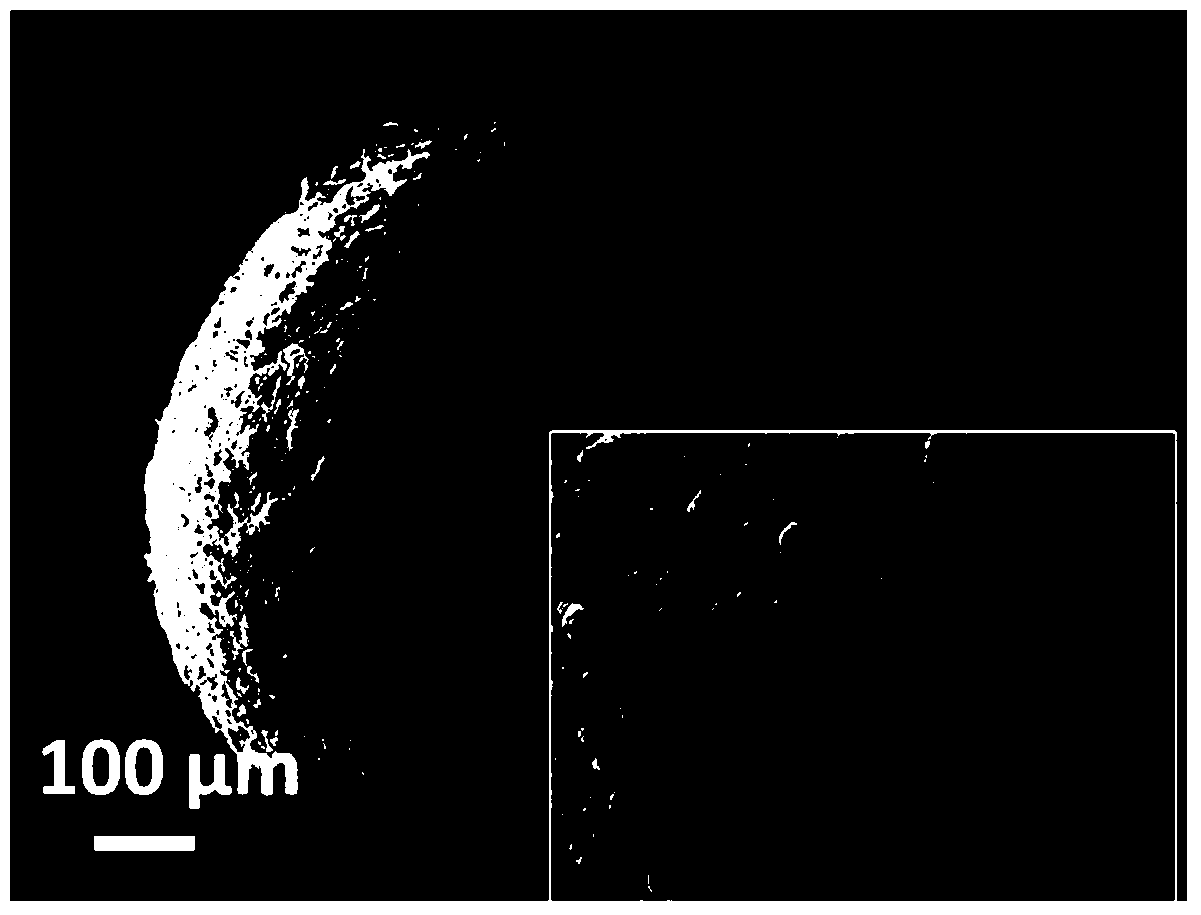

Image

Examples

Embodiment 1

[0082] (1) Homopolymerization of propylene

[0083] In a 500ml dry autoclave, first add 50ml of dry n-hexane, then successively add 1ml of triethylaluminum with a concentration of 1.8mol / L, 20.0mg of the carrier-type Ziegler-Natta catalyst A prepared above, and then feed propylene gas, at 60°C, under 0.2MPa pressure for 15 minutes, to obtain polypropylene particles, and directly proceed to the next step of reaction.

[0084] (2) Ethylene / propylene / diene copolymerization

[0085] Vent the propylene gas in the above step (1), then add 3ml of 1,9-decadiene monomer, and then feed the ethylene / propylene mixed gas with a gas molar ratio of 1:1, and the pressure in the polymerization system is 0.2 MPa, the copolymerization is carried out in a hexane solvent system, the polymerization temperature is controlled at 60° C., and the copolymerization reaction takes 45 minutes. After the polymerization was completed, the gas pressure in the autoclave was released, and the polymer was coll...

Embodiment 2

[0088] (1) Homopolymerization of propylene

[0089] In a 500ml dry autoclave, first add 100ml of dry n-hexane, then successively add 1ml of triethylaluminum with a concentration of 1.8mol / L, 20.0mg of the carrier-type Ziegler-Natta catalyst A prepared above, and then feed propylene gas, at 60°C, under 0.2MPa pressure for 15 minutes, to obtain polypropylene particles, and directly proceed to the next step of reaction.

[0090] (2) Ethylene / propylene / diene copolymerization

[0091] Vent the propylene gas in the above step (1), then add 3ml of 1,9-decadiene monomer, and then feed the ethylene / propylene mixed gas with a gas molar ratio of 1:1, and the pressure in the polymerization system is 0.5 MPa, the copolymerization is carried out in a hexane solvent system, the polymerization temperature is controlled at 60° C., and the copolymerization reaction takes 45 minutes. After the polymerization was completed, the gas pressure in the autoclave was released, the polymer was collect...

Embodiment 3

[0094] (1) Homopolymerization of propylene

[0095] In a 500ml dry autoclave, first add 100ml of dry n-hexane, then add 1ml of triethylaluminum with a concentration of 1.8mol / L, 20.0mg of the carrier-type Ziegler-Natta catalyst B prepared above, and then feed propylene Gas, polymerize at 60°C and 0.2MPa for 10 minutes to obtain polypropylene particles, and proceed to the next step of reaction directly.

[0096] (2) Ethylene / propylene / diene copolymerization

[0097] Vent the propylene gas in the above step (1), then add 8ml of 1,9-decadiene monomer, and then feed the ethylene / propylene mixed gas with a gas molar ratio of 1:2, and the pressure in the polymerization system is 0.5 MPa, the copolymerization is carried out in a hexane solvent system, the polymerization temperature is controlled at 60° C., and the copolymerization reaction takes 45 minutes. After the polymerization was completed, the gas pressure in the autoclave was released, and the polymer was collected and wash...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com