Mellow and fragrant Tieh-Kuan-Yin (an oolong tea) baking method

A baking method, the technology of Tieguanyin, which is applied in the field of roasting of Luzhou-flavored Tieguanyin, can solve the problems of uneven heating of tea leaves, unfavorable tea aroma, and high energy consumption, and achieve the goal of promoting environmental protection production, promoting the formation of good aroma, and uniform heating Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

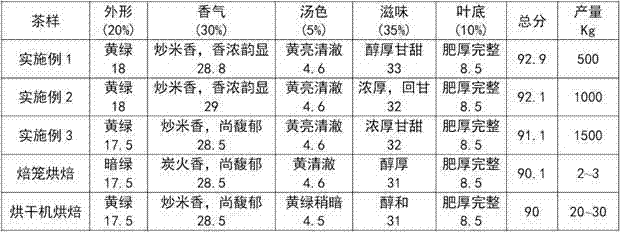

Embodiment 1

[0043] In the first step, 1200Kg of lychee wood is provided and burned in a smokeless stove. The heat (hot air) collected for baking and the wood aroma of lychee wood are sent to the chain plate dryer through the induced draft fan.

[0044] In the second step, 500 kg of refined Anxi Tieguanyin tea leaves are continuously put into the chain plate dryer from the tea storage bucket for the first baking. The thickness of the tea is 3cm, and the rotation speed is 70r / min. The temperature of the hot air inside the machine is 140°C, and the baking process takes 2.5 hours.

[0045] In the third step, the baked tea leaves are conveyed to the dryer for cooling through the conveyor belt, and the blower is used to send cold air for cooling. The speed of the blower is 1000r / min, and the speed of the dryer is 70r / min.

[0046] In the fourth step, the cooled tea leaves are sent to the uniform stacking room through the conveyor belt. The temperature of the uniform stacking room is controlled ...

Embodiment 2

[0051] In the first step, 1500Kg of longan wood is provided and burned in a smokeless stove. The heat (hot air) collected for baking and the wood aroma of longan wood are sent to the chain plate dryer through the induced draft fan.

[0052] In the second step, 1000 Kg of refined Anxi Tieguanyin tea leaves are continuously put into the chain plate dryer from the tea storage bucket for the first baking. The thickness of the tea is 4cm, and the rotation speed is 100r / min. The temperature of the hot air inside the machine is 145°C, and the baking process is 3 hours.

[0053] The third step is to transport the baked tea leaves to the dryer for cooling through the conveyor belt, and use the blower to send cold air for cooling. The blower speed is 1800r / min, and the dryer speed is 100r / min. Plate dryer.

[0054] In the fourth step, the cooled tea leaves are sent to the uniform stacking room through the conveyor belt. The temperature of the uniform stacking room is controlled at 15°C...

Embodiment 3

[0059] The first step is to provide a total of 1800Kg of lychee wood and longan wood, which are placed in a smokeless stove for combustion, and the heat (hot air) collected for baking and the wood aroma of lychee wood are sent to the chain plate dryer through the induced draft fan .

[0060] In the second step, 2000 Kg of refined Anxi Tieguanyin tea leaves are continuously put into the chain plate dryer from the tea storage bucket for the first baking. The thickness of the tea is 5cm, and the rotation speed is 120r / min. The temperature of the hot air in the machine is 150°C, and the baking process is 4 hours.

[0061] The third step is to convey the baked tea leaves to the dryer through the conveyor belt for cooling, and use the blower to send cold air for cooling. The blower speed is 2500r / min, and the dryer speed is 120r / min. Plate dryer.

[0062] In the fourth step, the cooled tea leaves are sent to the uniform stacking room through the conveyor belt. The temperature of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com