A kind of preparation method of magnetic health glove

A magnetic and glove technology, used in gloves, magnetic therapy, electrotherapy and other directions, can solve the problems of poor moisture permeability, reduce the anti-pilling ability of the fabric, reduce the strength of the fabric, etc., and achieve flexible production, strong operability and controllability. , the effect of strong market adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

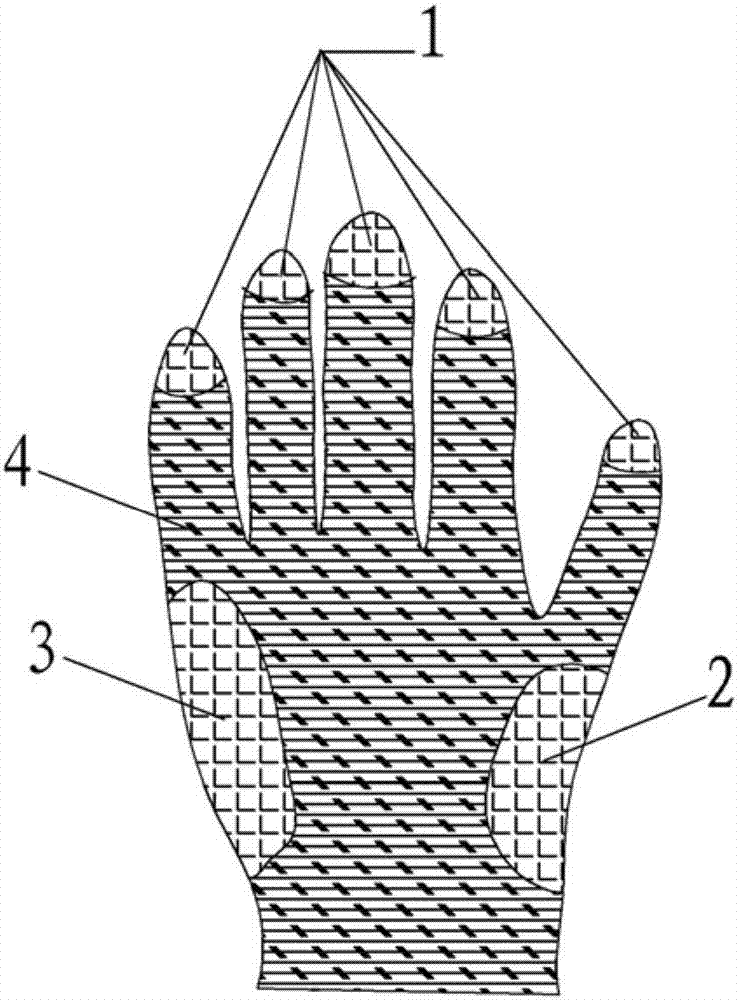

[0034] (1) Using magnetic polypropylene fiber and conventional fiber as raw materials, it is manufactured by knitting method, wherein the ratio of magnetic polypropylene fiber to conventional fiber is 1:0.2, and the magnetic base cloth 4 with a surface average magnetic induction intensity of 0.05mT is obtained.

[0035] (2) Cut the magnetic base cloth 4 into a glove-shaped base cloth, and add 0.002g / cm2 to the fingertips of the glove 2 The magnetic powder to form the first magnetic powder part 1, add 0.008g / cm to the big thenar part of the palm 2 The magnetic powder to form the second magnetic powder part 2, add 0.004g / cm2 to the edge of the palm 2 The magnetic powder is used to form the third magnetic powder part, and the part where the magnetic powder is added is coated with a binder, and the surface of the magnetic powder is covered with a base cloth of the same shape as the magnetic powder covered part to obtain a magnetic base cloth containing magnetic powder.

[0036] (...

Embodiment 2

[0038] (1) Using magnetic polypropylene fibers and conventional fibers as raw materials, adopt the method of weaving to manufacture, wherein, magnetic polypropylene fibers are used as weft threads, conventional fibers are used as warp threads, the weft density is 20 threads / cm, and the warp density is 40 threads / cm. A magnetic base cloth 4 with a surface average magnetic induction of 0.035mT.

[0039] (2) Cut the magnetic base fabric 4 into a glove-shaped base fabric, and add 0.003g / cm2 to the fingertips of the glove 2 The magnetic powder to form the first magnetic powder part 1, add 0.015g / cm to the big thenar part of the palm 2 The magnetic powder to form the second magnetic powder part 2, add 0.009g / cm2 to the edge of the palm 2 The magnetic powder is used to form the third magnetic powder part, and the part where the magnetic powder is added is coated with a binder, and the surface of the magnetic powder is covered with a base cloth of the same shape as the magnetic powde...

Embodiment 3

[0042] (1) Using magnetic polypropylene fiber and conventional fiber as raw materials, it is manufactured by non-woven manufacturing method, wherein the ratio of magnetic polypropylene fiber to conventional fiber is 1:1, and the magnetic base cloth 4 with a surface average magnetic induction intensity of 0.027mT is obtained.

[0043] (2) Cut the magnetic base cloth 4 into a glove-shaped base cloth, and add 0.002g / cm2 to the fingertips of the glove 2The magnetic powder to form the first magnetic powder part 1, add 0.008g / cm to the big thenar part of the palm 2 The magnetic powder to form the second magnetic powder part 2, add 0.009g / cm2 to the edge of the palm 2 The magnetic powder is used to form the third magnetic powder part, and the part where the magnetic powder is added is coated with a binder, and the surface of the magnetic powder is covered with a base cloth of the same shape as the magnetic powder covered part to obtain a magnetic base cloth containing magnetic powder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com