Large-flow vertical radial flow adsorption device with characteristic of layered parallel connection design, and method thereof

An adsorber and radial flow technology, which is applied in the field of large-flow vertical radial flow adsorbers, can solve the problems of small footprint, increased height, and high flow field uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

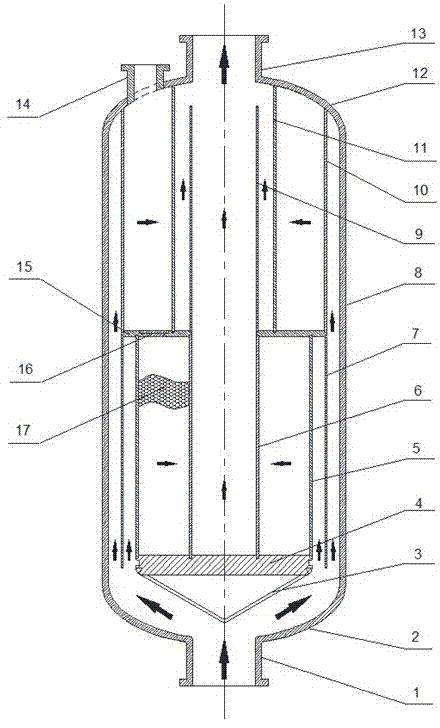

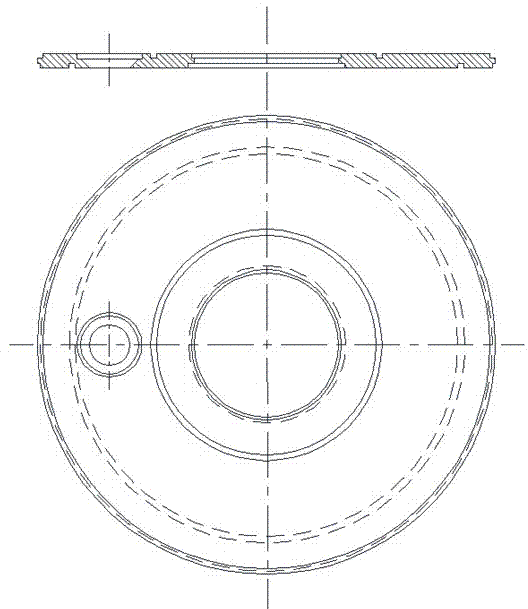

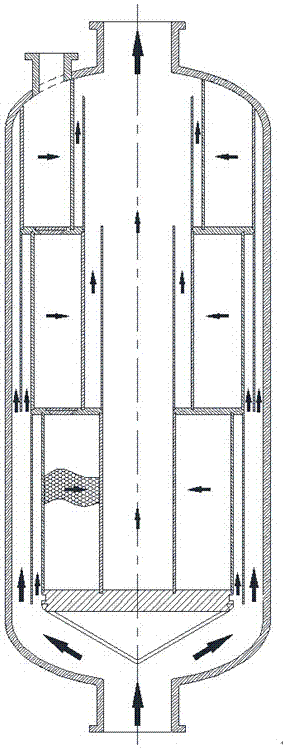

[0016] Such as figure 1 As shown, a large-flow vertical radial flow adsorber with a layered parallel design includes an inlet pipe 1, a bottom spherical tank 2, a rectifying plate 3, a bottom support plate 4, a porous distribution tube 5 outside the lower unit, and a porous distribution tube inside the lower unit. Distribution cylinder 6, outer guide cylinder 7, adsorber cylinder 8, inner guide cylinder 9, upper unit outer porous distribution cylinder 10, upper unit inner porous distribution cylinder 11, top spherical tank 12, exhaust pipe 13, top packing Port 14, middle baffle 15, middle baffle packing cover 16, adsorbent filling layer 17; bottom spherical tank 2, adsorber cylinder 8, top spherical tank 12, top packing port 14 are welded together to form the shell of the adsorber body, the bottom of the shell is provided with an air intake pipe 1, and the top is provided with an exhaust pipe 13, and the two ends of the porous distribution cylinder on the inner 11 and outer 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com