Constant-tension installing winch for steel wire rope and cable

A constant tension, steel wire rope technology, applied in the field of marine engineering, can solve the problems of abandoned wire ropes or cables, unable to meet the tension requirements well, unstable tension, etc., and achieve the effect of reducing losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in detail below in conjunction with the accompanying drawings.

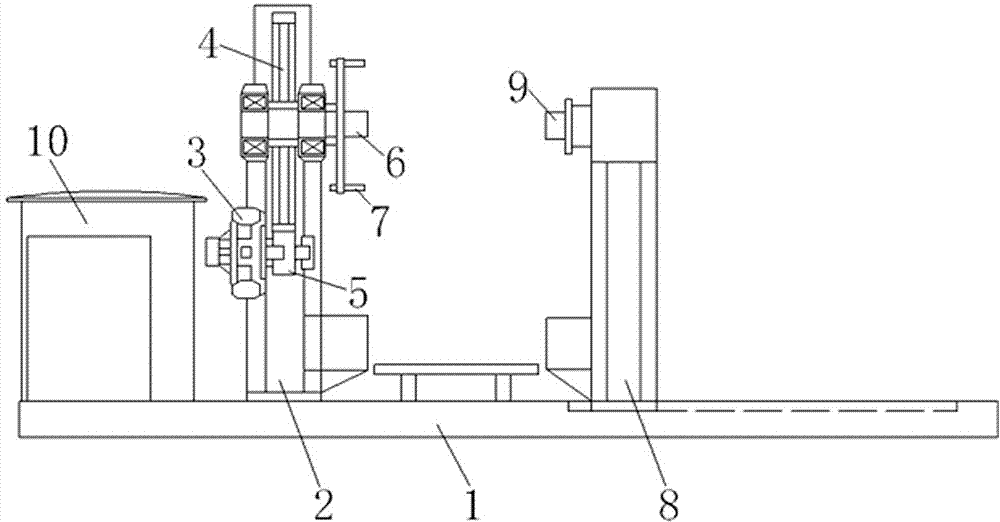

[0012] Such as figure 1 As shown, a constant tension installation winch for wire ropes and cables includes a base 1, a fixed bracket 2 fixedly connected to the base 1, a reduction gear transmission mechanism arranged on the fixed bracket 2, and the power of the reduction gear transmission mechanism The hydraulic motor 3 connected to the input end, the driving shaft 6 connected to the power output end of the reduction gear transmission mechanism arranged on the upper end of the fixed bracket 2 through the bearing, the fork device 7 arranged on the driving shaft 6, and the base 1 slide The cooperation of the rails can move left and right and is connected to the mobile bracket 8 on the base 1, the driven shaft 9 that is arranged on the upper end of the mobile bracket 8 through bearings facing the driving shaft 6, the hydraulic station that provides oil pressure for the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com