Biochar and preparation method

A technology of biochar and plant straw, which is applied in the field of biochar and its preparation, can solve the problems of large specific surface area, single source of bio-black carbon, different effect of increasing soil fertility and passivation of heavy metals, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] 1. Collect plant-sourced biochar (rice straw), chop it and air-dry it to ensure that its moisture content is less than 20%. Collect animal-derived biochar (pig manure), air-dry and mix to ensure that its moisture content should be lower than 40%.

[0019] 2. Mix the rice straw and pig manure according to the weight ratio of 2:1, and put it in the furnace (half the volume).

[0020] 3. Carry out high-temperature anaerobic firing at 500 degrees Celsius for 10 hours.

Embodiment 2

[0022] 1. Collect plant-sourced biochar (rice straw), chop it and air-dry it to ensure that its moisture content is less than 20%. Collect animal-derived biochar (pig manure), air-dry and mix to ensure that its moisture content should be lower than 40%.

[0023] 2. Mix rice straw and pig manure according to the weight ratio of 2:1, and load the furnace (full). 3. Carry out high-temperature anaerobic firing at 550 degrees Celsius for 20 hours.

experiment example 1

[0024] Experimental Example 1 Optimization of Proportion

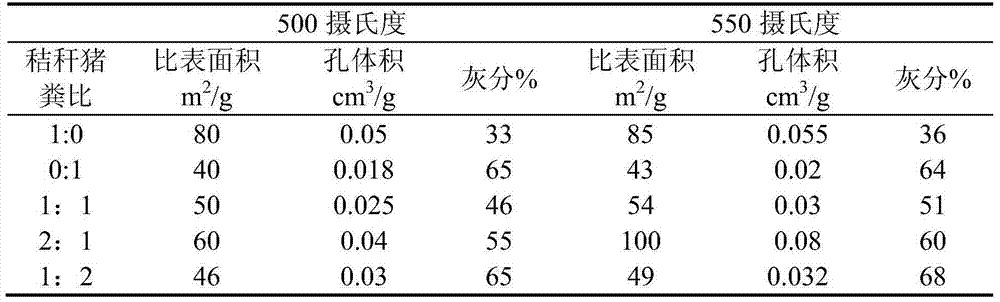

[0025] In this experimental example, by adjusting the ratio of plant straw and animal manure, the specific surface area, pore volume and ash content of biochar fired at different ratios were compared (see Table 1).

[0026] It was found that the specific surface area of the biochar product obtained was 60-100m2 when plant straw and animal manure were anaerobically fired at 500-550 degrees Celsius for 10-20 hours at a weight ratio of 2:1. 2 / g, the pore volume is 0.04-0.08cm 3 / g, the ash content is 55-60%, obviously better than the ratio of 1:1 and 1:2. At the same time, compared with the black carbon derived from straw in the prior art, although its specific surface area and pore volume have decreased by 25% and 20%, its ash content has increased by 66.7%; compared with black carbon derived from pig manure, although its ash content has decreased 15.4%, but its specific surface area and pore volume increased by 50%...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com