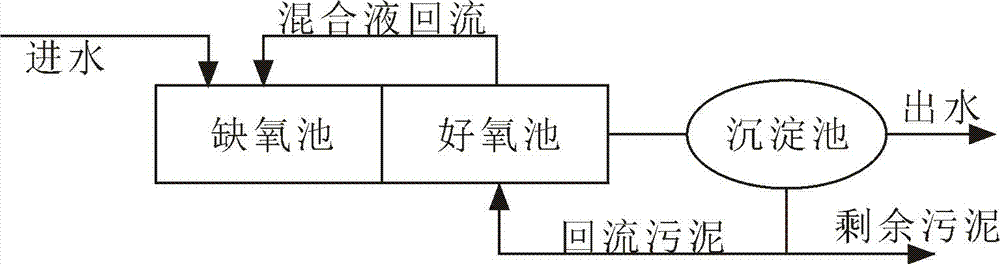

A/O reactor capable of achieving reflux without pump

A reactor and pump reflux technology, applied in the field of A/O denitrification devices, can solve the problems of extra energy consumption and achieve the effects of energy saving, large sedimentation area, and slow water flow rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

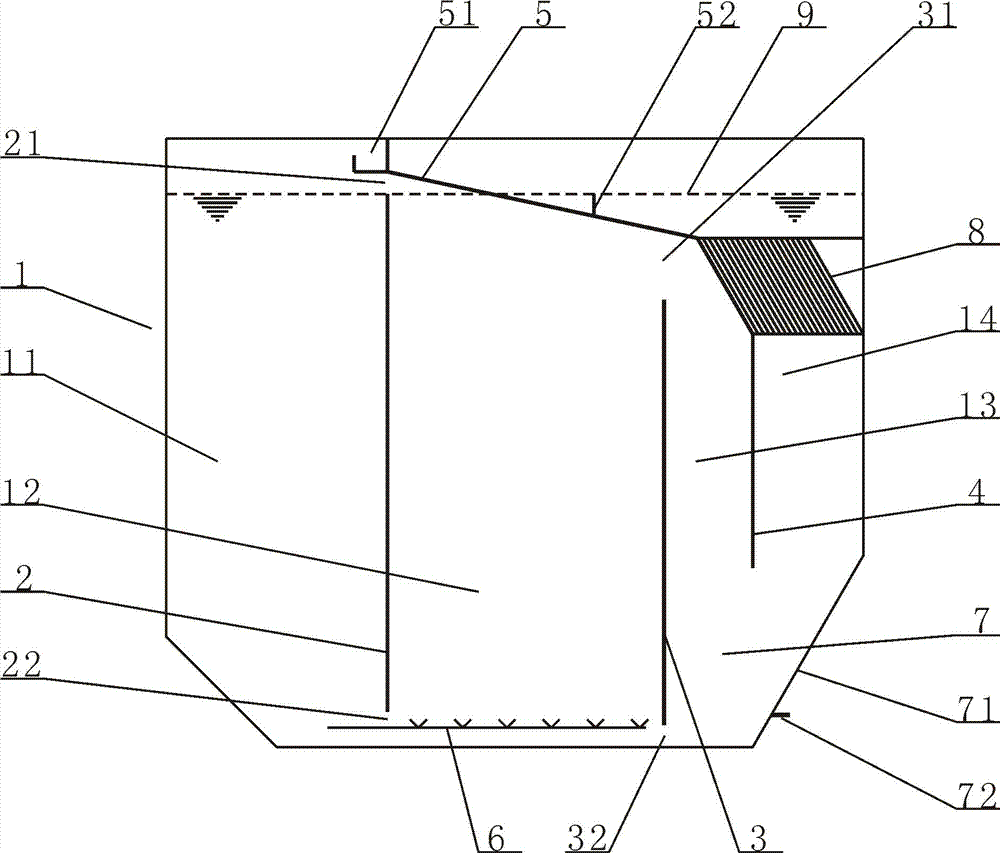

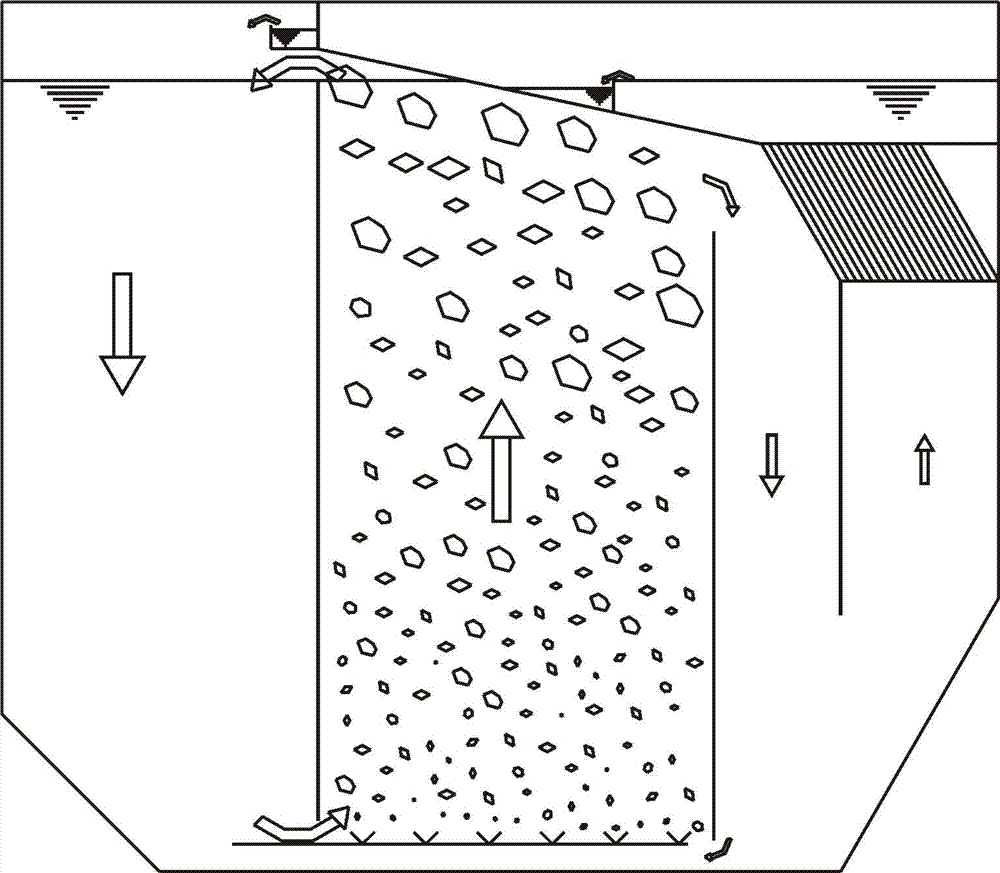

[0017] Description of the marks involved in the accompanying drawings: reactor 1, anoxic tank 11, aerobic tank 12, sedimentation buffer zone 13, sedimentation zone 14; first partition 2, mixed solution return port 21, mixed solution inflow port 22, The second partition 3, the mixed liquid discharge port 31, the sludge return port 32, the third partition 4, the cover plate 5, the water inlet weir plate 51, the water outlet weir plate 52, the microporous aerator 6, the mud bucket 7, Slope 71, sludge discharge port 72, sloping plate packing 8, water surface 9.

[0018] The technical scheme and working process of the pumpless reflux A / O reactor of the present invention will be described in detail below with reference to the accompanying drawings and examples.

[0019] Such as figure 2 As shown, the A / O reactor 1 without pump backflow includes anoxic tank 11, aerobic tank 12 and sedimentation tank. The bottom of the aerobic tank 12 is provided with a microporous aerator 6, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com