Steel for wind power, and production method thereof

A technology of wind power and impact energy, which is applied in the field of steel materials, can solve the problems of poor low temperature toughness, general low temperature performance, and low strength, and achieve the effects of ensuring low yield ratio, optimized low temperature performance, and excellent low temperature toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

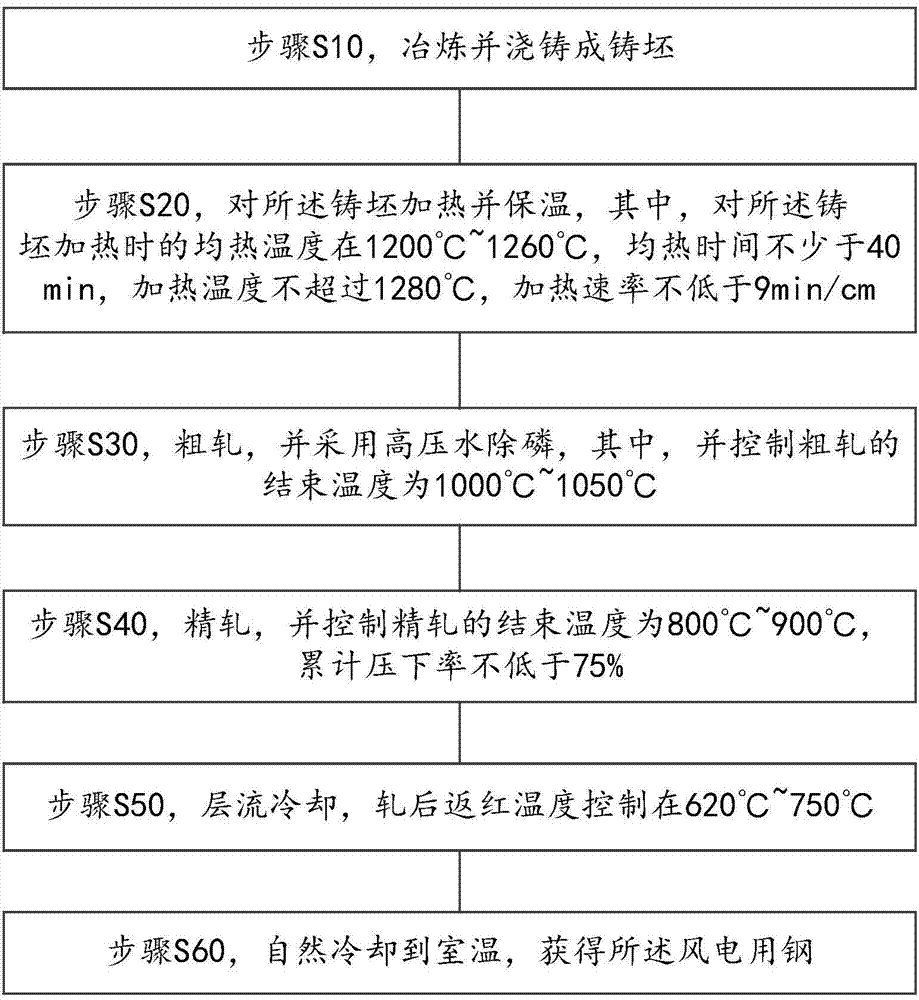

[0038] In order to better understand the above-mentioned technical solution, the above-mentioned technical solution will be described in detail below in conjunction with the accompanying drawings and specific implementation methods.

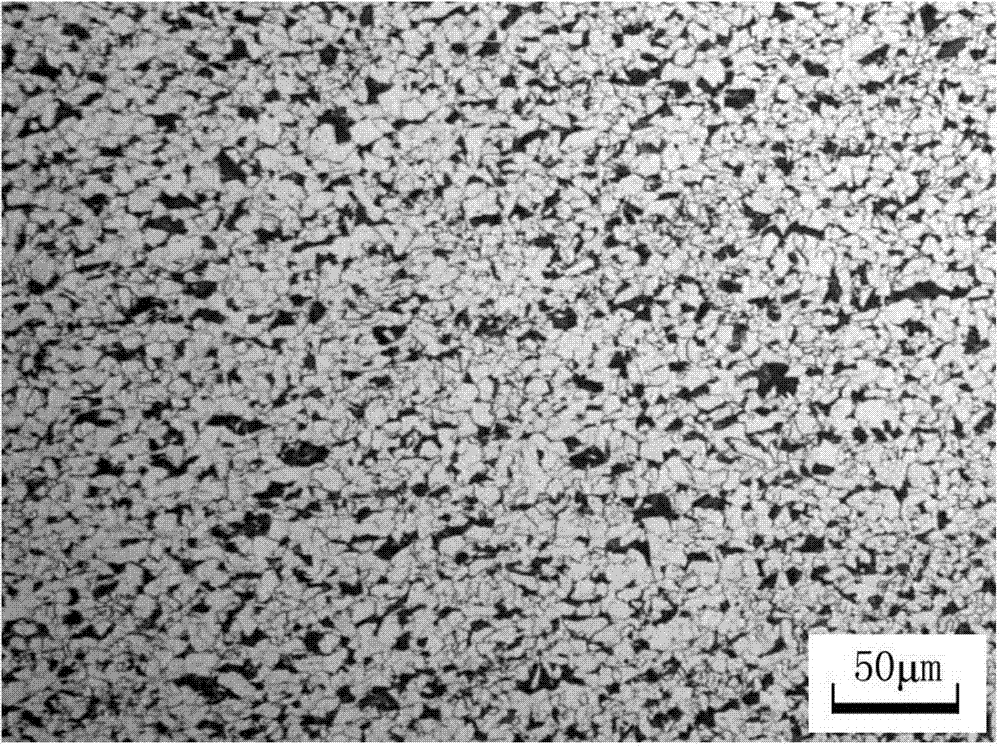

[0039] Among the steel sheets used for steel for wind power, there are increasing demands on the steel sheets for high strength, low yield ratio, excellent low-temperature toughness, and the like. In response to the above requirements, the present invention provides a steel for wind power, such as figure 1 As shown, the yield strength of the wind power steel is ≥ 420MPa, the tensile strength is 600-680MPa, the elongation A is ≥ 30%, the impact energy value at -40°C is greater than or equal to 230J, and the impact energy value at -60°C is greater than or equal to 200J. Ratio ≤ 0.70.

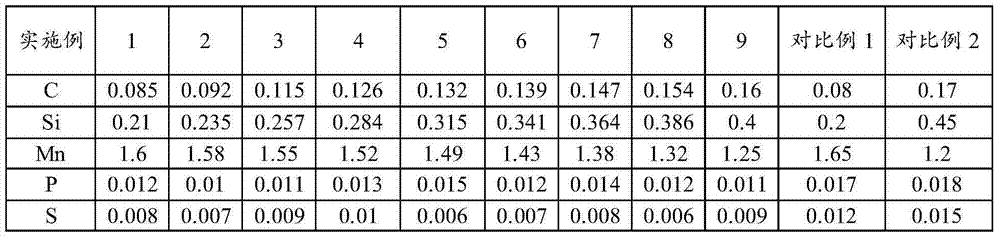

[0040] The mass percentage of steel for wind power specifically includes: C (carbon): 0.085-0.16%, Si (silicon): 0.21-0.40%, Mn (manganese): 1.25-1.60%, P (phosphorus...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com