Hollow coaxial drag motor test bench for real-time measurement of motor rotor temperature rise

A technology for real-time measurement of motor rotors, applied in the direction of temperature measurement of moving solids, etc., can solve problems such as low accuracy, poor rotor cooling effect, and deviation, and achieve the effect of improving accuracy and avoiding mechanical disturbances.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with drawings and embodiments.

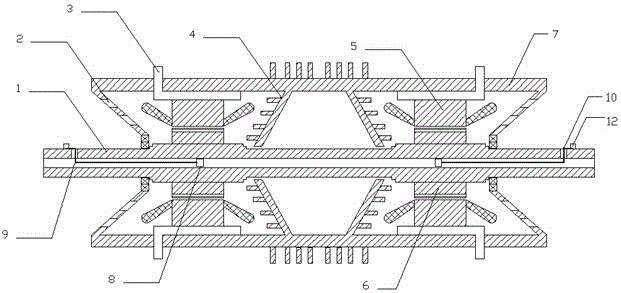

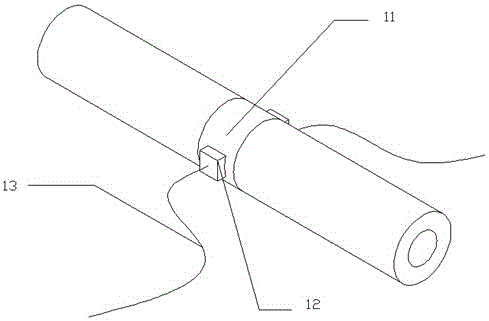

[0019] Such as figure 1 As shown, two pair-towing motor rotors 6 of the present invention share the same pair-towing hollow rotating shaft 1 and the same casing 7, and the casing 7 is sleeved on the pair-towing hollow rotating shaft 1 through bearings, and two sets of motors are housed in the casing 7. Towing motor; two motor rotors 6 are respectively fixedly sleeved on both ends of the hollow rotating shaft 1 shared by the towing, and the motor stator 5 is installed on the outer periphery of the motor rotor 6 and fixed on the inner wall of the casing 7; both ends of the casing 7 are open and useful In the air-cooling channel 2 for cooling, a water-cooling channel 3 is provided on the casing 7 at the place of each traction motor, and a cooling fin 4 is provided in the middle of the casing 7 .

[0020] There is a central hole in the shared hollow rotating shaft 1 for to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com