Processing method of combined high-speed electromagnet core

A technology of high-speed electromagnet and processing method, which is applied in the direction of electromagnet with armature, inductance/transformer/magnet manufacturing, electromagnet, etc. Low processing cost, high processing efficiency, convenient and smooth perfusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

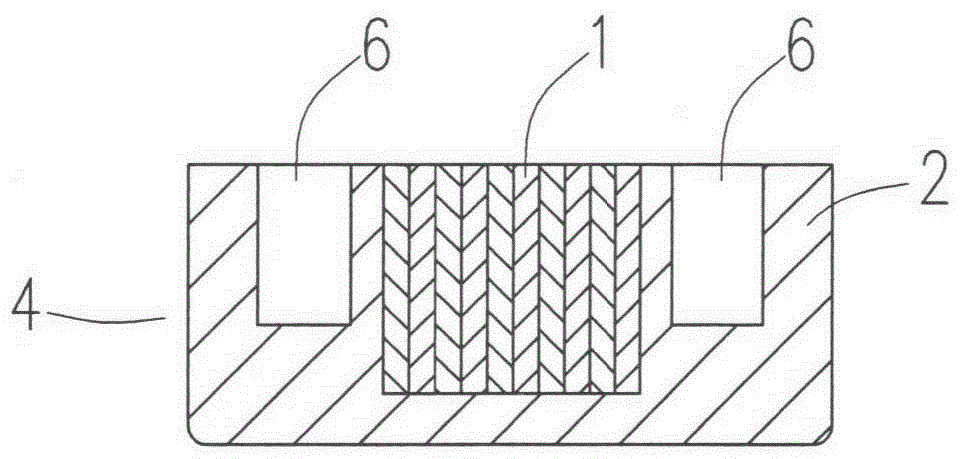

[0026] A processing method for a combined high-speed electromagnet core is characterized in that it comprises the following steps: (see Figure 1 to Figure 8 )

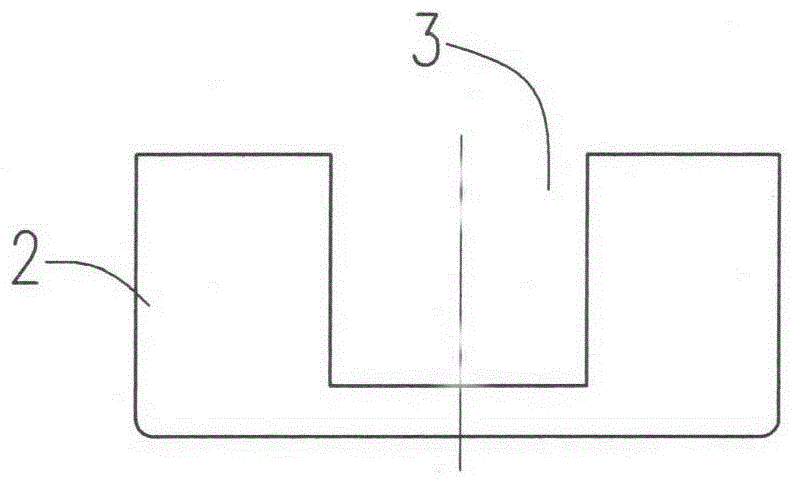

[0027] a, a conventional method is processed to form a cylindrical iron core seat 2 with a radial through groove 3;

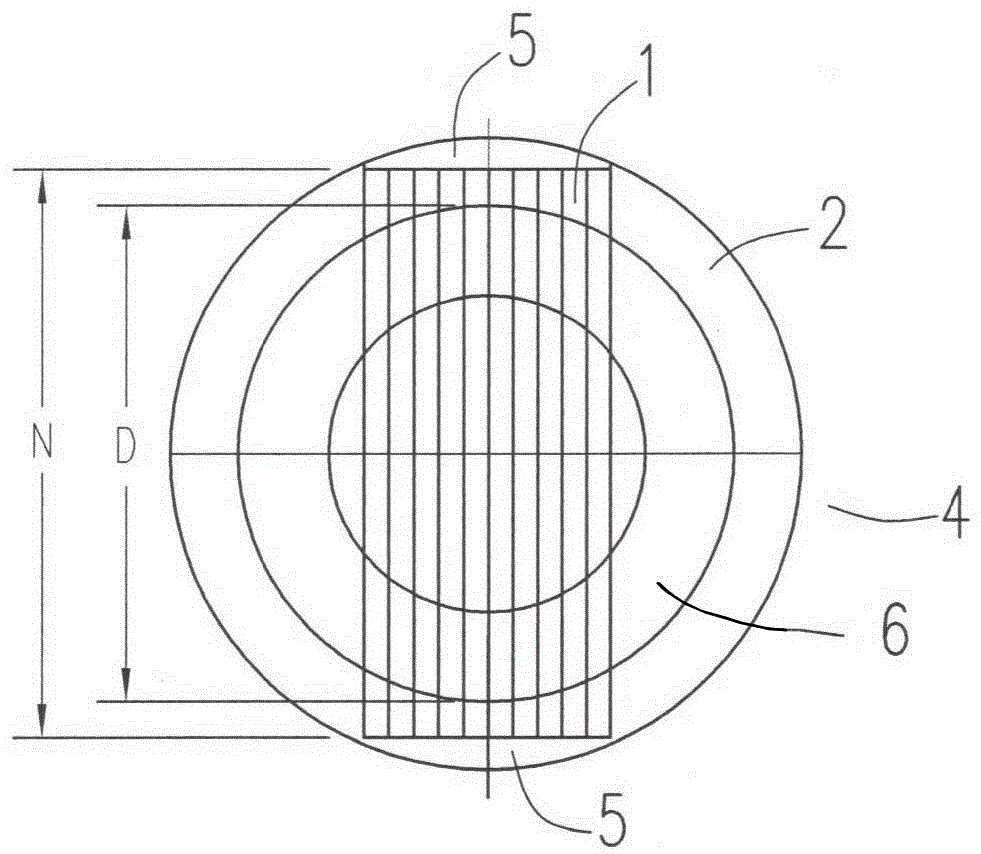

[0028] b, cutting the silicon steel strip with a thickness of 0.2mm into a rectangular silicon steel sheet 1 with the same length and width, the length M of the silicon steel sheet 1, the length N of the radial through groove 3, and the outer diameter D of the annular coil groove 6 satisfy the following Relational formula: D<M=N;

[0029] c. Embed several pieces of rectangular silicon steel sheets 1 into the radial through grooves 3 of the iron core seat 2, plug them tightly, and assemble them into a blank of the iron core assembly 4 with a pair of notches 5 on both sides;

[0030] d. The blank is welded by argon arc welding at a pair of gaps 5. After the welding is completed, several silicon steel s...

Embodiment 2

[0033] A processing method for a combined high-speed electromagnet core is characterized in that it comprises the following steps:

[0034] a. A cylindrical iron core seat with a radial through groove is processed by the conventional method;

[0035] b. Cut the 0.5mm thickness silicon steel strip into rectangular silicon steel sheets with the same length and width. The length M of the silicon steel sheet, the length N of the radial through groove, and the outer diameter D of the annular coil groove satisfy the following relationship: D Figure 9 );

[0036] c. Embed several pieces of rectangular silicon steel sheets into the radial through grooves of the iron core seat, plug them tightly, and assemble them into a blank of an iron core assembly with a pair of notches on both sides;

[0037] d. The blank is welded by argon arc welding at a pair of gaps. After the welding is completed, several silicon steel sheets are connected with the core seat to form a core assembly;

[003...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com