Small scr flue gas denitrification ammonia injection control system and method

A control method and denitration technology, applied in the field of denitration ammonia injection control system, can solve the problems of difficulty in meeting real-time and precise control, overcomplexity and cost, and lack of a very mature and reliable small-scale SCR denitration control system, achieving simple structure and low cost. , the effect of reducing the content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

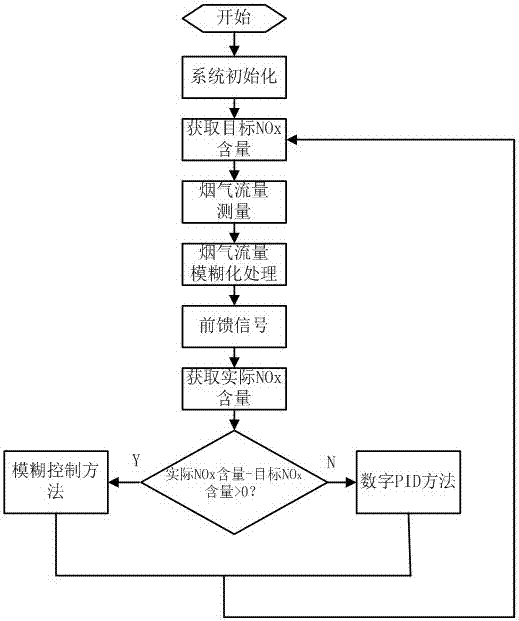

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

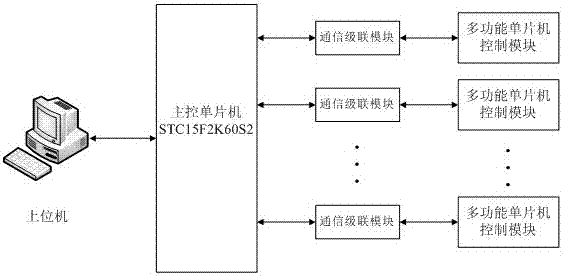

[0024] Such as figure 1 As shown, the small-scale SCR flue gas denitrification ammonia injection control system of the present invention includes a main control single-chip microcomputer connected with an upper computer, and the main control single-chip microcomputer is respectively connected with a plurality of functional single-chip microcomputer control modules through a communication cascading module; the model of the main control single-chip microcomputer is STC15F2K60S2

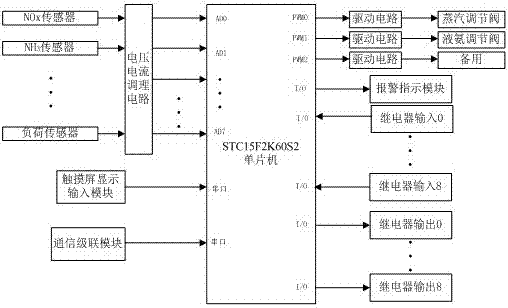

[0025] Such as figure 2 As shown, the multifunctional single-chip microcomputer control module includes a single-chip microcomputer, the model of the single-chip microcomputer is STC15F2K60S2, and the input end of the single-chip microcomputer is connected to multiple smoke detection sensors through a voltage and current conditioning circuit, and the voltage ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com