Method for preparing epoxy resin for casting dry type transformer

A technology of dry-type transformers and epoxy resins, applied in the manufacture of inductors/transformers/magnets, electrical components, circuits, etc., can solve the problems of high partial discharge, generation of bubbles, easy generation of bubbles, etc., to increase impact resistance and resistance flammability, reduced generation of air bubbles, and increased insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

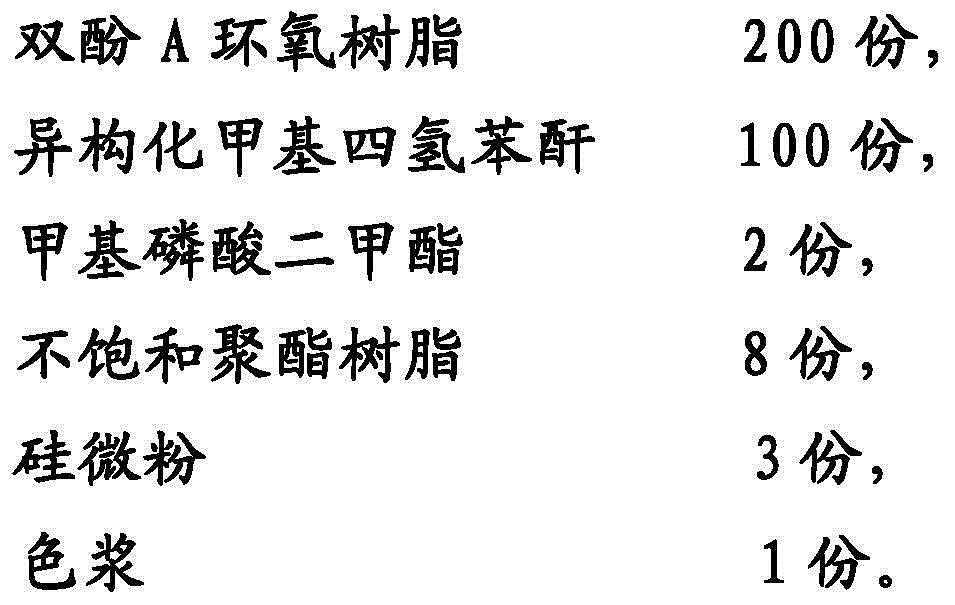

[0019] The invention provides a method for preparing an epoxy resin cast dry-type transformer, wherein the epoxy resin composition is fed according to the following parts by weight.

[0020]

[0021] The pouring process is:

[0022] In the first step, put the weighed silicon micropowder in a container, place it in a pouring pot and dry it together with the coil at a temperature of 120°C, then put epoxy resin, isomerized methyl tetrahydrophthalic anhydride, methyl phosphoric acid di Methyl ester, unsaturated polyester resin, silicon micropowder, and color paste are heated in a heating furnace, and the temperature of the furnace is adjusted to 70 ° C for 4 hours;

[0023] In the second step, mixing, the dried raw materials are mixed 30 minutes before pouring;

[0024] In the third step, when the material tank is heated to 70°C, start the tank vacuum pump, suck the epoxy resin mixture into the material tank, and degas for 20 minutes;

[0025] The fourth step is to maintain a...

Embodiment 2

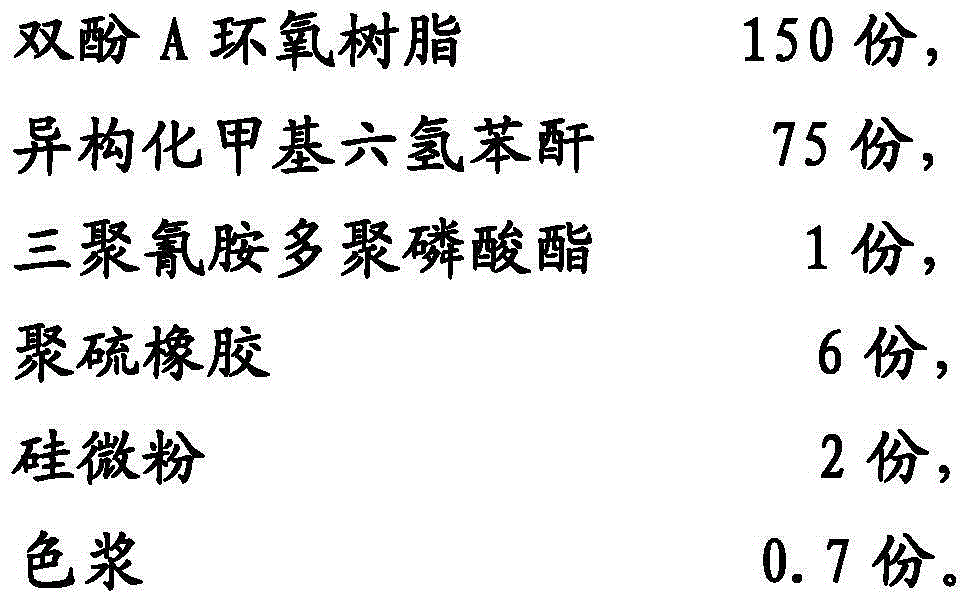

[0027] The invention provides a method for preparing an epoxy resin cast dry-type transformer, wherein the epoxy resin composition is fed according to the following parts by weight.

[0028]

[0029] Epoxy resin casting dry-type transformers are carried out in the following steps:

[0030] The first step is to put the weighed silicon powder in a container, place it in a pouring pot and dry it with the coil at a temperature of 130°C, and then put epoxy resin, curing agent, flame retardant, plasticizer, silicon powder , the color paste is placed in a heating furnace to heat up, and the temperature of the furnace is adjusted to 80°C for 4.5 hours;

[0031] In the second step, mixing, the dried raw materials are mixed 35 minutes before pouring;

[0032] In the third step, when the material tank is heated to 80°C, start the material tank vacuum pump, suck the epoxy resin mixture into the material tank, and degas for 25 minutes;

[0033] The fourth step is to maintain a vacuum ...

Embodiment 3

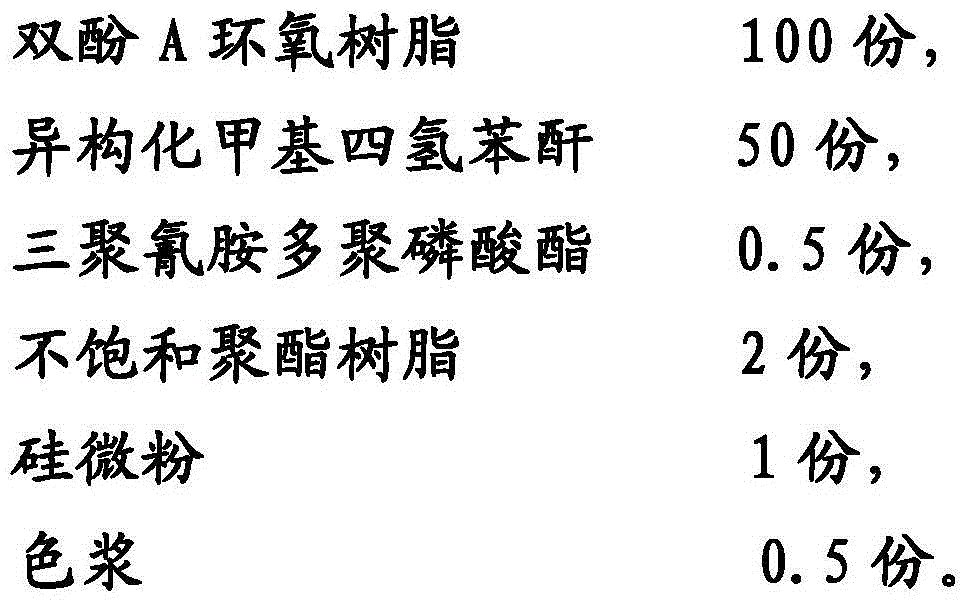

[0035] The invention provides a method for preparing an epoxy resin cast dry-type transformer, wherein the epoxy resin composition is fed according to the following parts by weight.

[0036]

[0037] Epoxy resin casting dry-type transformers are carried out in the following steps:

[0038] The first step is to put the weighed silica powder in a container, place it in a pouring pot and dry it together with the coil at a temperature of 140°C, and then put epoxy resin, curing agent, flame retardant, plasticizer, silica powder , the color paste is placed in a heating furnace to heat up, and the temperature of the furnace is adjusted to 90 ° C for 5 hours;

[0039] In the second step, mixing, the dried raw materials are mixed 35 minutes before pouring;

[0040] In the third step, when the material tank is heated to 90°C, start the tank vacuum pump, suck the epoxy resin mixture into the material tank, and degas for 40 minutes;

[0041] The fourth step is to maintain a vacuum of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com