A kind of vehicle and its wheel drive system and wheel drive torque distribution method

A wheel-side drive and torque distribution technology, applied in the control of drive, vehicle components, electric vehicles, etc., can solve the problems of unguaranteed transmission efficiency, unsuitable multi-axis system, complex control methods, etc., to save power consumption and comfort. Good performance and safety, wear-reducing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be described in further detail below in conjunction with the accompanying drawings.

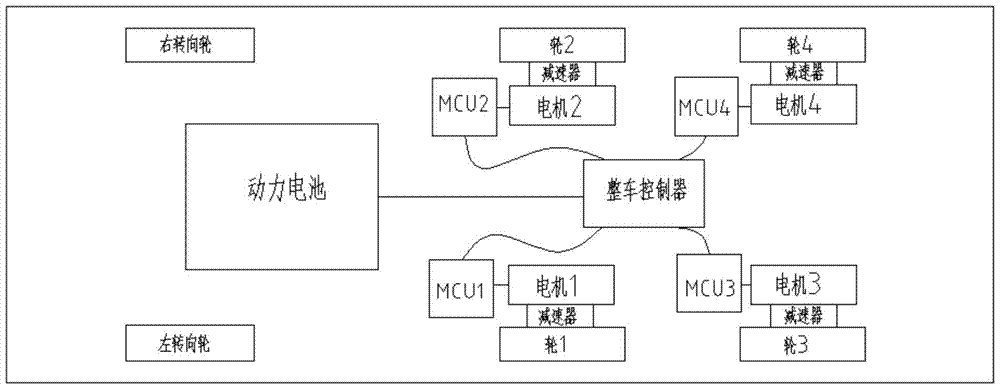

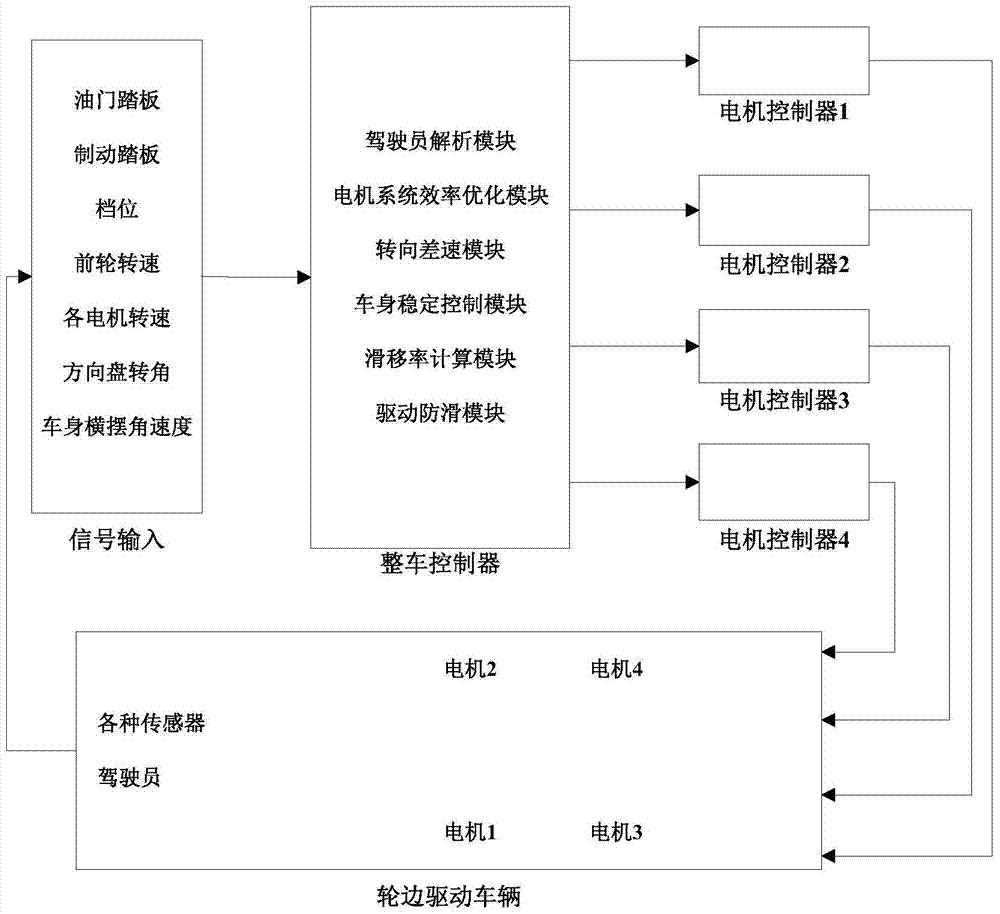

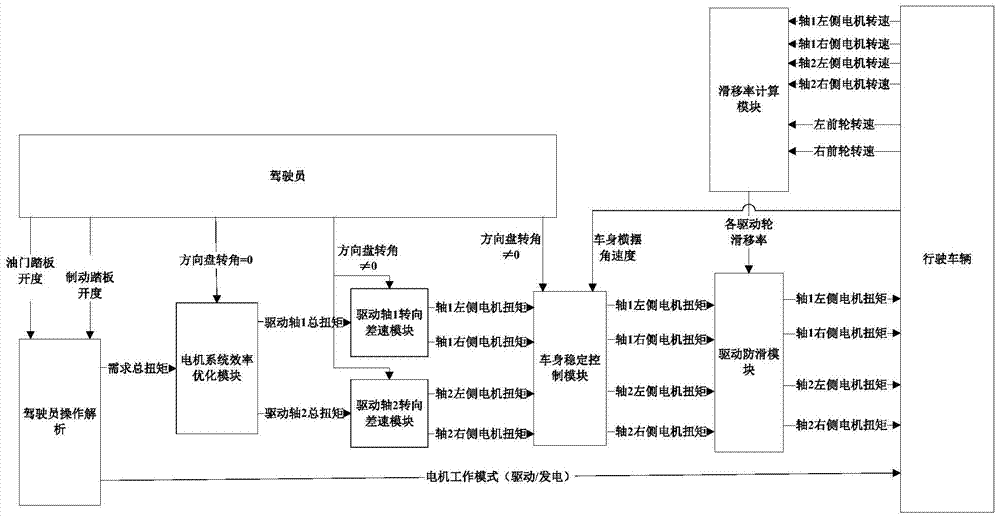

[0046] Such as figure 1Shown is the overall structural diagram of the vehicle wheel drive system of the present invention. It can be seen from the figure that the system includes a multi-axis wheel drive device and its control unit. The multi-axis wheel drive device includes a steering shaft and m drive shafts. m≥2 (m generally takes 2 or 3, figure 1 In the shown m=2), two steering wheels are installed on the steering shaft, and 2m electric wheels are installed on the drive shaft, and each electric wheel is composed of a corresponding wheel motor, a reducer and a tire; the control unit includes a vehicle The controller and 2m motor controllers, that is, each wheel side motor is connected to a corresponding motor controller through the circuit, and the vehicle controller is connected to each motor controller, and information exchange is performed through the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com