Automatic salvage ship for garbage on water surface

A technology for surface garbage and salvage boats, applied in the field of sanitation equipment, can solve problems such as low work efficiency, high labor intensity, hidden safety hazards, etc., and achieve the effects of convenient operation and maintenance, improved salvage efficiency, and reduced labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with accompanying drawing.

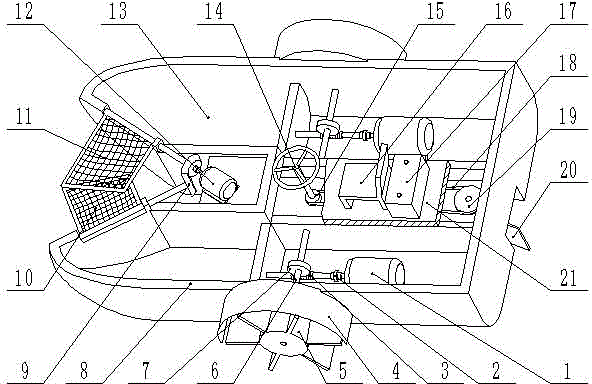

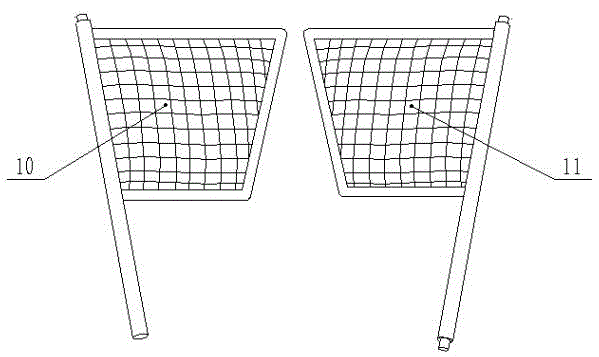

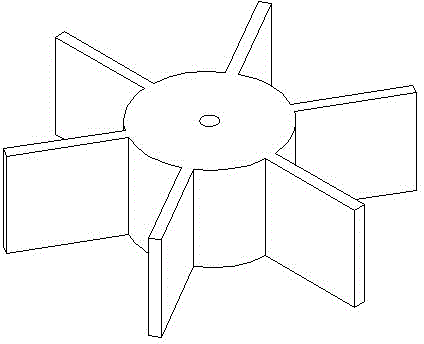

[0014] see Figure 1~Figure 3 The utility model relates to an automatic salvage ship for surface garbage. The ship has a left-right symmetrical structure and is composed of a hull, a salvage device installed on the hull, a direction control device, a power supply, a power device and a power transmission device. The motor (1) transmits the power to the impeller (5) through the worm (3) and the worm wheel (7), and the impeller (5) rotates to push the hull (8) forward; the steering wheel (14) is connected with the small pulley (15), The large belt pulley (19) is connected with the rudder (20), and the steering wheel (14) rotates left and right through the belt (18) to drive the rudder (20) to swing left and right to control the forward direction of the hull (8); the low-speed motor (12) and the hull (8) The salvage net II (11) at the front end is connected, the salvage net II...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com