Device for subpacking chemical reagent for metal surface treatment

A metal surface treatment and chemical reagent technology, applied in the field of machinery, can solve problems such as operator injury, reduce drug properties, and enterprise losses, and achieve the effects of reducing reactions, simple structure, and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

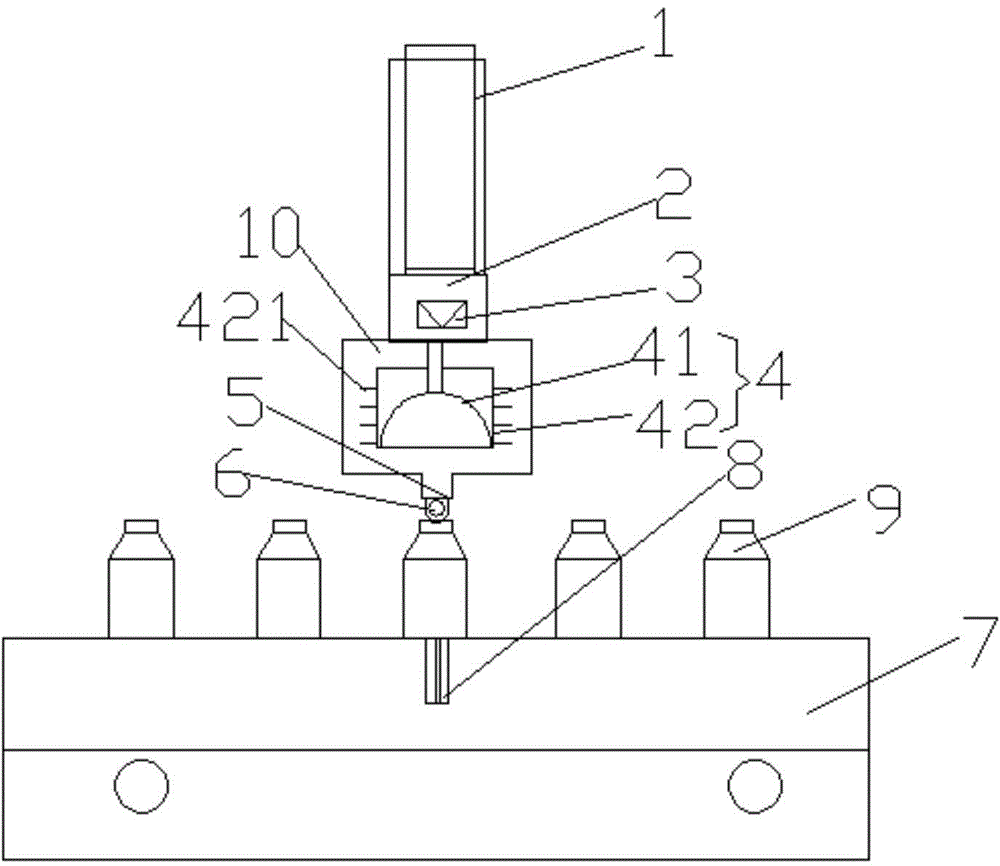

[0017] Example: such as figure 1 As shown, a dispensing device for metal surface treatment chemical reagents of the present invention includes a servo motor 1, a coupling 2, a screw mechanism 3, a stirring device 4, an inner stirrer 41, an outer frame stirrer 42, and a baffle 421, dropper 5, detection switch 6, conveying case 7, positioning device 8, medicine bottle 9 and tank 10, a coupling 2 is installed under the servo motor 1, and a screw mechanism is installed under the coupling 2 3. A stirring device 4 is connected below the screw mechanism. The stirring device 4 is arranged in the tank body 10. The stirring device 4 includes an inner stirrer 41 and an outer frame agitator 42. The outer frame of the hollow rectangular structure stirs The outer end of the device 42 is connected with a baffle 421, a dropper 5 is provided at the center of the bottom end of the tank body 10, a detection switch 6 is provided on the dropper 5, and the medicine bottle 9 is arranged on the droppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com