A kind of composite sole of natural rubber and eva combination and preparation technology thereof

A technology of composite sole and preparation process, applied in footwear, other household appliances, applications, etc., can solve the problems of inability to meet the requirements of softness and lightness, poor tear strength, and inability to meet the needs of daily training, and achieve high-strength Training requirements, the effect of maintaining high elasticity and high tear strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

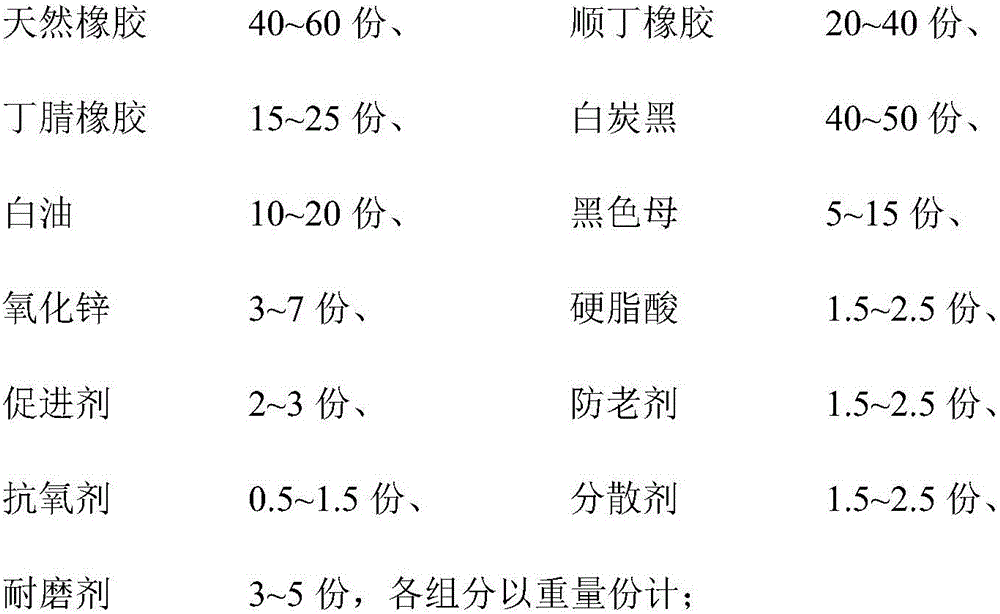

[0035] Embodiment 1: the compound sole of a kind of natural rubber and EVA combination, comprise rubber outsole and EVA middle end, described rubber outsole comprises following component:

[0036]

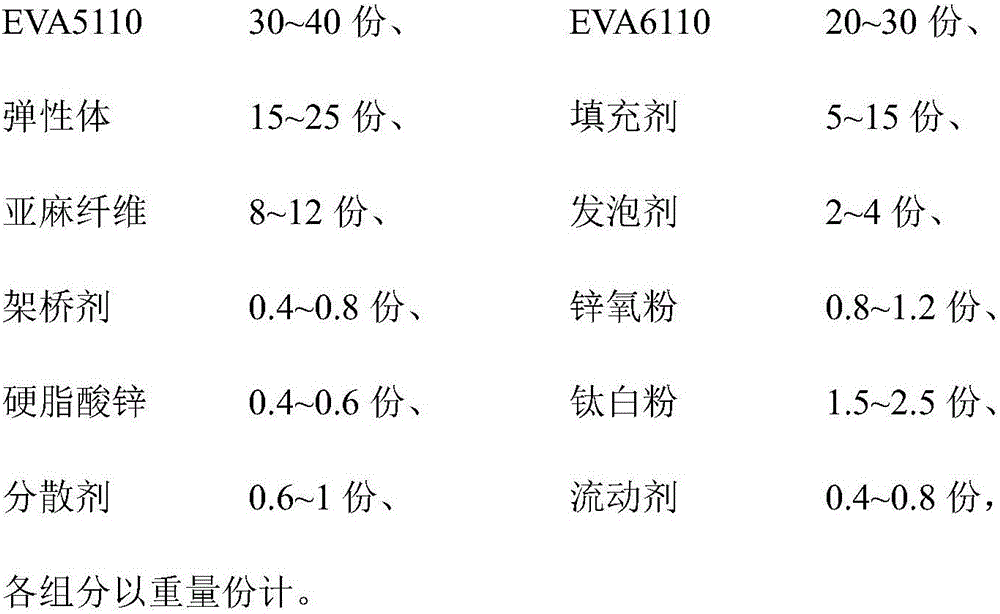

[0037] The EVA midsole includes the following components:

[0038]

[0039]

[0040] The preparation technology of the composite sole of this natural rubber and EVA combination, comprises the steps:

[0041] (1) Preparation of EVA midsole:

[0042] a. Put EVA5110, EVA6110, elastomer, filler and flax fiber into the internal mixer and knead for 2 minutes. When the temperature is 80°C, add zinc oxide powder, zinc stearate, titanium dioxide, dispersant and flow agent, and continue Mix for 5 minutes, when the temperature is 105°C, add foaming agent and bridging agent and mix for 7 minutes;

[0043] b. After the internal mixing is completed, put the material on the open mill, the temperature of the open mill is 80°C, 15m / m thin pass twice, and 1m / m thin pass again;

[0044] c...

Embodiment 2

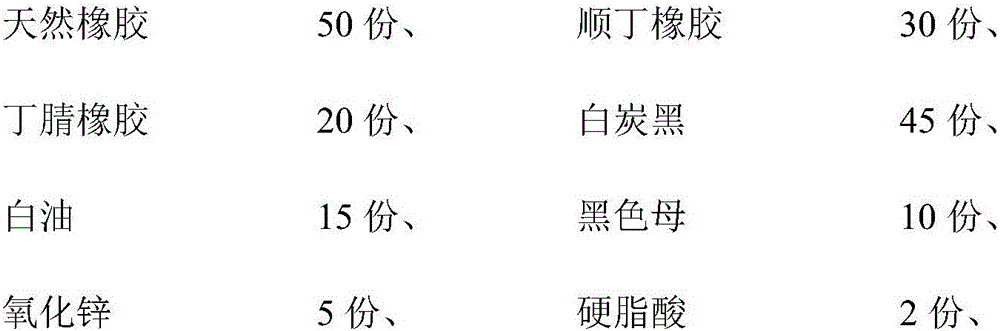

[0057] Embodiment 2: a kind of composite sole of natural rubber and EVA combination, comprise rubber outsole and EVA middle end, described rubber outsole comprises following component:

[0058]

[0059] The EVA midsole includes the following components:

[0060]

[0061] The preparation technology of the composite sole of this natural rubber and EVA combination, comprises the steps:

[0062] (1) Preparation of EVA midsole:

[0063] a. Put EVA5110, EVA6110, elastomer, filler and flax fiber into the internal mixer and knead for 4 minutes. When the temperature is 100°C, add zinc oxide powder, zinc stearate, titanium dioxide, dispersant and flow agent, and continue Mix for 7 minutes, when the temperature is 115°C, add foaming agent and bridging agent and mix for 9 minutes;

[0064] b. After the internal mixing is completed, put the material on the open mill, the temperature of the open mill is 90°C, 15m / m thin pass twice, and 1m / m thin pass again;

[0065] c. Put the refi...

Embodiment 3

[0078] Embodiment 3: a kind of compound sole of natural rubber and EVA combination, comprise rubber outsole and EVA middle end, described rubber outsole comprises following component:

[0079]

[0080] The EVA midsole includes the following components:

[0081]

[0082] The preparation technology of the composite sole of this natural rubber and EVA combination, comprises the steps:

[0083] (1) Preparation of EVA midsole:

[0084] a. Put EVA5110, EVA6110, elastomer, filler and flax fiber into the internal mixer and knead for 3 minutes. When the temperature is 90°C, add zinc oxide powder, zinc stearate, titanium dioxide, dispersant and flow agent, and continue Mix for 6 minutes, when the temperature is 110°C, add foaming agent and bridging agent and mix for 8 minutes;

[0085] b. After the internal mixing is completed, put the material on the open mill, the temperature of the open mill is 85°C, 15m / m thin pass twice, and 1m / m thin pass again;

[0086] c. Put the refine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com