A kind of preparation method of chitosan binder for shaped activated carbon

A technology for forming activated carbon and chitosan, applied in the direction of chitin adhesive, hyaluronic acid adhesive, etc., can solve the problems of dust pollution, reduced treatment efficiency, large resistance, etc., and achieves good water resistance, convenient operation, simple craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] A preparation method for chitosan binder for shaped activated carbon, comprising the following steps:

[0026] Step 1) Add water to configure an acid solution with a certain concentration, weigh an appropriate amount of chitosan and dissolve it in the acid solution;

[0027] Step 2) adding the cross-linking agent into the chitosan solution under stirring, and controlling the mass ratio of chitosan and cross-linking agent;

[0028] Step 3) Add an appropriate amount of activated carbon to the reaction system to control the ratio of binder and activated carbon;

[0029] Step 4) Control the temperature of the reaction system at 20-60°C, cross-link the mixed solution for 1-2 hours under stirring, place it in the air for 2 hours, and remove the foam;

[0030] Step 5) Put the reaction solution in an oven at 100-120° C. for 15-30 minutes, and finally pour the reaction solution into a mold and dry it.

[0031] Further, the acid is mainly citric acid.

[0032] Further, the cro...

Embodiment 1

[0035] Preparation of chitosan-citric acid thermal crosslinking binder:

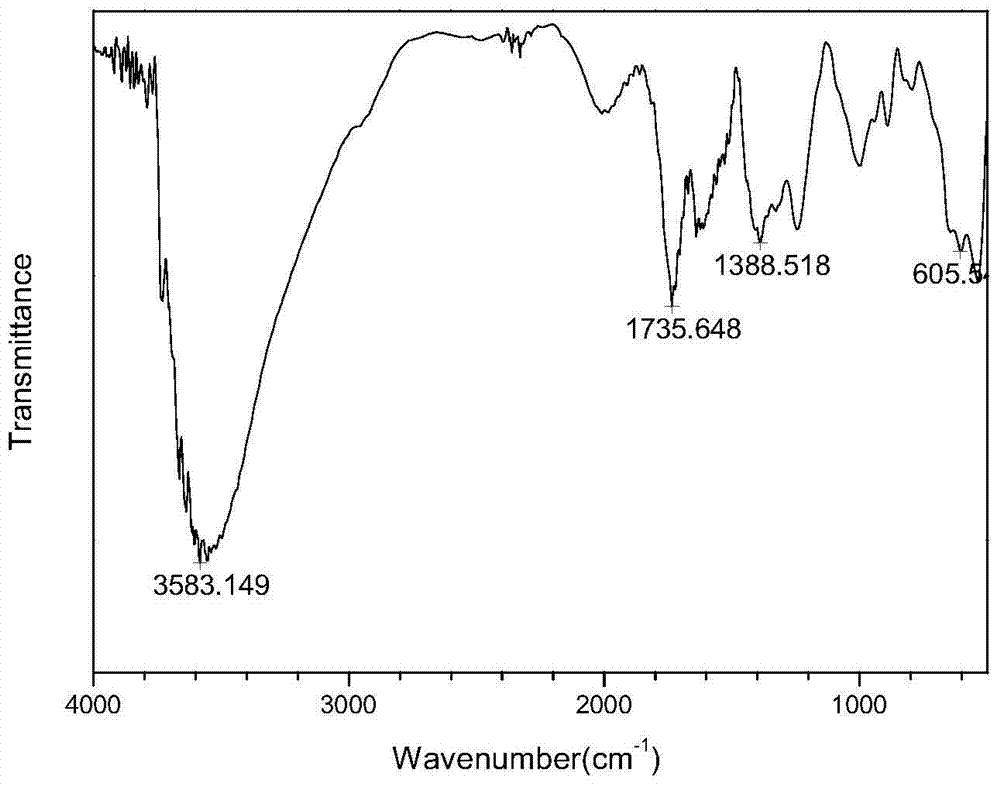

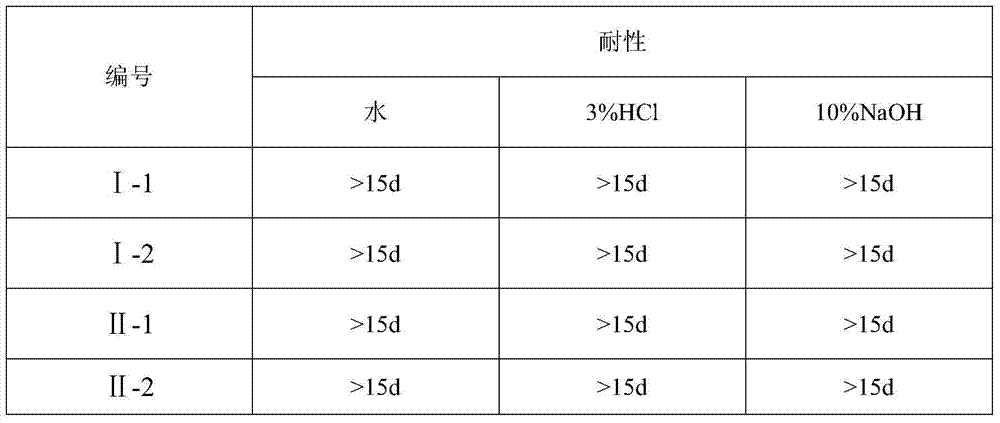

[0036] Chitosan-citric acid binder composite activated carbon samples were prepared under heating. Get 1g of chitosan, add it to 50ml of 7% by weight aqueous solution of citric acid, stir until dissolved. Stir and add a certain amount of activated carbon, control the gel / carbon ratio to 1:1, 2:1, put the solution in a drying oven at 120°C, and take it out after half an hour. The product was transferred to a mold and placed in air to dry at room temperature. Chitosan and citric acid in the activated carbon mixture can be cross-linked by reacting at 100-120 °C for half an hour. The prepared composite activated carbon samples were subjected to long-term immersion experiments in water, 3wt% HCl aqueous solution, and 10wt% NaOH aqueous solution. Studies have found that the chitosan-citric acid binder system has no swelling in water, acid, and alkali solutions, can maintain the original particle shape, and c...

Embodiment 2

[0040] Implementation of chitosan-citric acid-glutaraldehyde binder:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com