Flame-retardant low-voc particle board and preparation method thereof

A particleboard and particle technology, which is applied in the field of flame-retardant and low-VOC particleboard and its preparation, achieves the effects of excellent fire resistance, simple production process and high promotion value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The preparation method of flame-retardant low-VOC particleboard of the present invention comprises:

[0029] Mixing moso bamboo with miscellaneous bamboos to obtain mixed bamboo chips, said miscellaneous bamboos including any one or any combination of two or three kinds of bamboos in Cizhu, mottled bamboo, and palm bamboo, the mass ratio of moso bamboo and miscellaneous bamboos is 1: 0 to 3:1 range,

[0030] or,

[0031] Mixing eucalyptus with miscellaneous wood to obtain mixed wood, said miscellaneous wood including poplar, fruit wood, pine wood or any combination of two or three combinations, the mass ratio of eucalyptus and miscellaneous wood is 1 : 0 to 3:1 range;

[0032] Chipping and planing the mixed bamboo chips or wood to obtain shavings;

[0033] Drying the shavings so that the moisture content of the shavings is within the range of 6% to 16%;

[0034] Use the secondary cyclone separator to sort the dried shavings, and use the water curtain dust removal me...

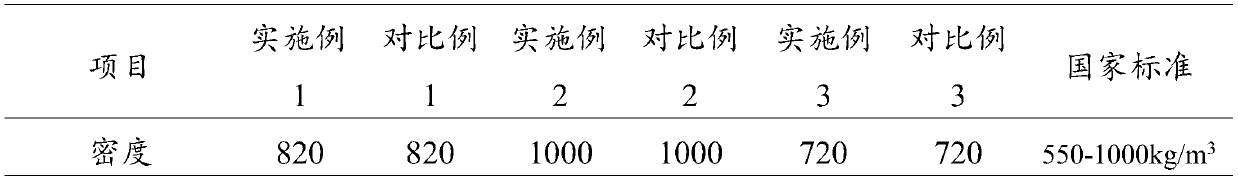

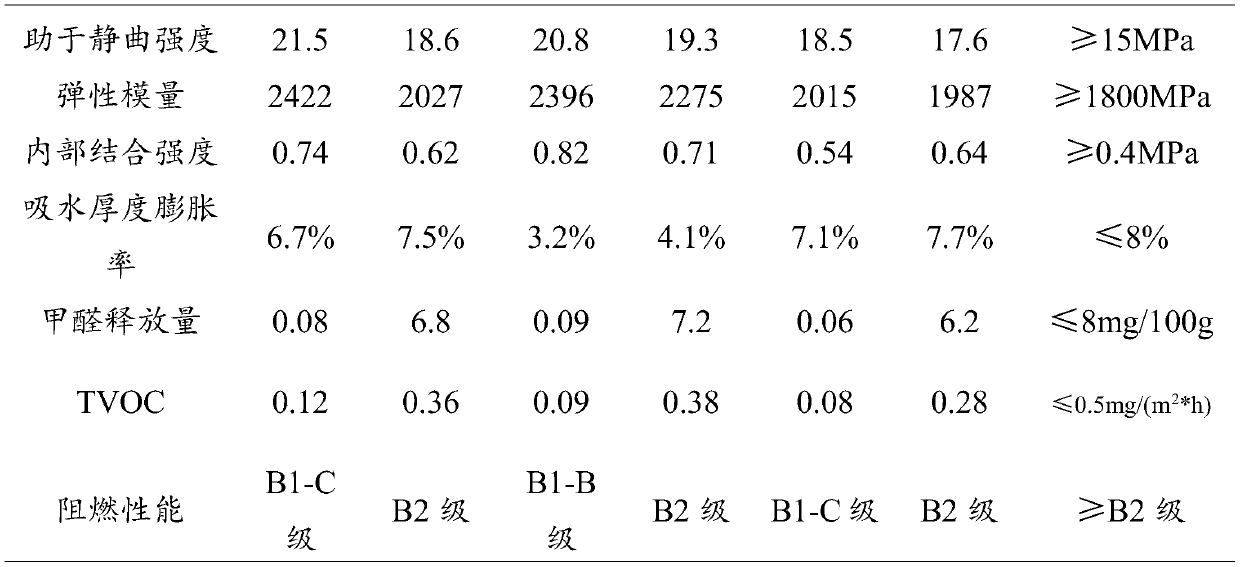

Embodiment 1

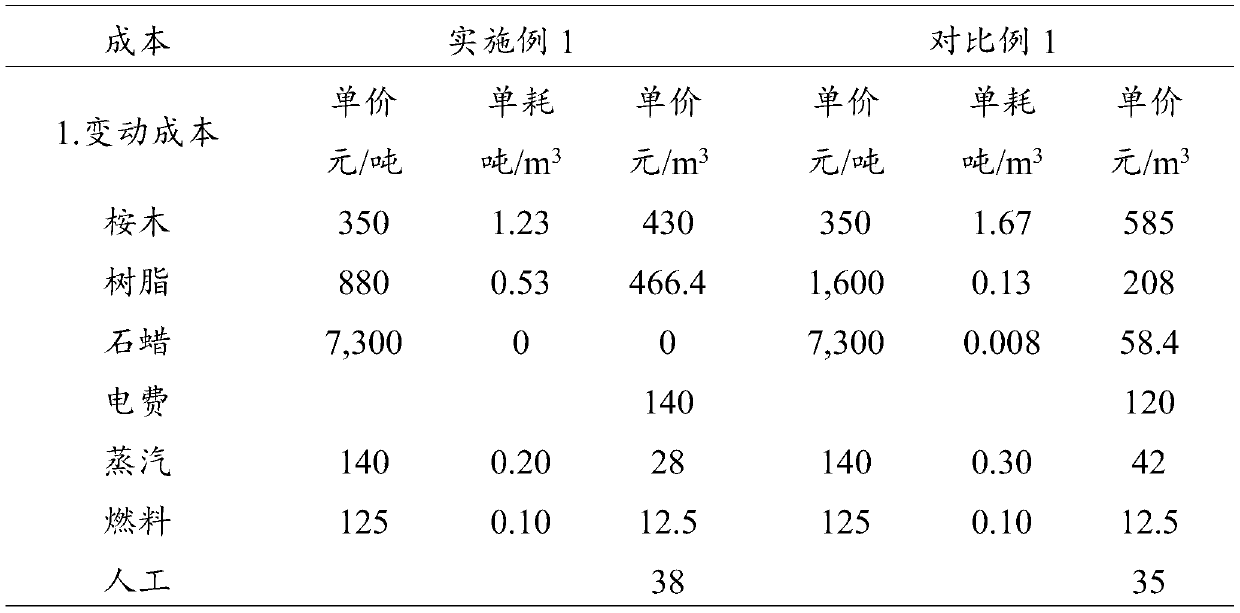

[0064] Embodiment 1: Take eucalyptus as raw material, press thickness 12.0mm, density 820kg / m 3 Floor type wood-based particleboard. The process steps are as follows: first chip the eucalyptus raw material to obtain wood chips with a length of 30 mm, a width of 20 mm and a thickness of 3 mm, and then obtain wood shavings by shaving. The wood shavings are dried by a roller drier for 0.5min until the moisture content reaches 15%, and then enter the secondary cyclone separation system, and go through the water curtain dust removal system to remove smoke and large particle shavings. The shavings from the secondary cyclone separator are mechanically separated and enter the rubber mixing system of the surface core layer respectively. At the same time, flame retardant resin is added (ratio of glyoxal: melamine: dicyandiamide: ammonium phosphate: ammonia = 3.5 : 1.8: 0.6: 1.2: 0.3) and enhancer (mass ratio montmorillonite: urotropine: attapulgite powder: magnesium chloride powder: ma...

Embodiment 2

[0065] Embodiment 2: Take moso bamboo: miscellaneous bamboo=mass ratio 3:1 as raw material, press thick 12.0mm, density 1000kg / m 3 Floor type bamboo particleboard. The process steps are as follows: the raw materials are chipped first to obtain bamboo chips with a length of 30mm, a width of 20mm and a thickness of 3mm, and then bamboo shavings are obtained by shaving. The bamboo shavings are dried by a roller dryer for 0.6min, and the dry moisture content reaches 14%, and then enter the secondary cyclone separation system. After the smoke and dust are treated in the wet spray tower, the smoke and large particles of wood shavings are removed by the electrostatic precipitator system. The bamboo shavings from the secondary cyclone separator are mechanically separated and enter the surface core layer glue mixing system respectively. At the same time, flame-retardant resin (the amount of the substance is more 3.3: 2.0: 0.6: 1.4: 0.5) and enhancer (mass ratio montmorillonite: urotro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com