Preparation method of charcoal and charcoal

A charcoal and carbonization technology, which is applied in the field of preparation of clean and environmentally friendly charcoal, can solve the problems of destroying soil cultivability, affecting gardens, destroying soil fertility, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

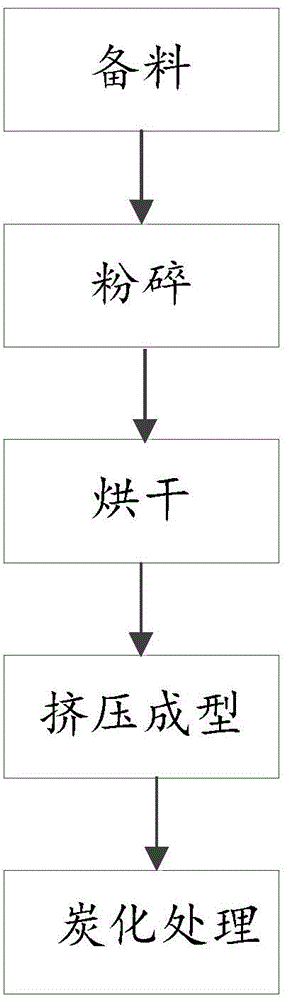

[0019] figure 1 A schematic flow diagram of the charcoal preparation method of the present invention is shown in . Such as figure 1 As shown, the preparation method includes: after the raw materials are prepared, the raw materials are pulverized, dried, extruded, and carbonized to obtain a charcoal product. The raw materials are one or more of sawdust, branches, rice husks, peanut shells, walnut shells, Eupatorium adenophorum and crop straws. Further preferably, the weight ratio of the raw materials is: 10-20 parts of sawdust, 10-20 parts of branches, 10-30 parts of rice husks, 10-20 parts of peanut shells, 10-30 parts of walnut shells, 10 parts of Eupatorium adenophorum -30 parts and a mixture of 10-30 parts of crop straw.

[0020] The branches used in the raw materials can be branches of any tree species, such as pine branches, mulberry branches, eucalyptus branches and the like. The crop straw used may be any crop straw, such as corn straw, wheat straw, sorghum straw an...

Embodiment 1

[0028] A kind of preparation method of charcoal comprises in the present embodiment:

[0029] A mixture of 10 parts of sawdust, 15 parts of pine branches, 30 parts of rice husks, 20 parts of peanut shells, 15 parts of walnut shells, 20 parts of Eupatorium adenophorum and 10 parts of corn stalks is selected as raw materials, and the raw materials are pulverized to The particle size is 6mm. Dry the pulverized particles at 200°C for 3 hours to make the moisture content reach 20%, extrude and cut them at 160°C to obtain firewood rods, ignite the firewood rods in a carbonization furnace, and after 20 hours The temperature in the furnace was raised to 330° C., and charcoal was obtained after closing the carbonization furnace for 3 days.

Embodiment 2

[0031] Select a mixture of 15 parts of sawdust, 10 parts of eucalyptus branches, 20 parts of rice husks, 10 parts of peanut shells, 30 parts of walnut shells, 10 parts of Eupatorium adenophorum and 30 parts of wheat straw as raw materials, and crush the raw materials to The particle size is 8mm, and the crushed particles are dried at 250°C for 2 hours to make the moisture content reach 12%, extruded and cut at 200°C to obtain a fuel rod, and the fuel rod is ignited in a carbonization furnace, and after 25 hours The temperature in the furnace was raised to 350° C., and charcoal was obtained after closing the carbonization furnace for 4 days.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com