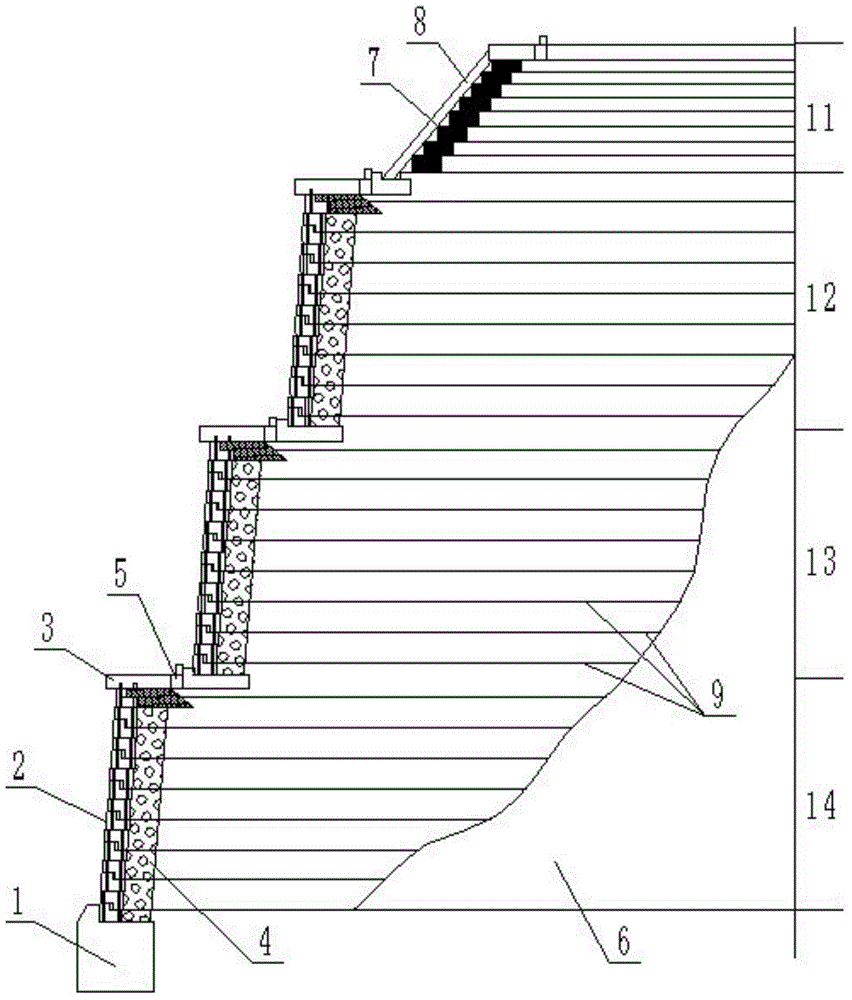

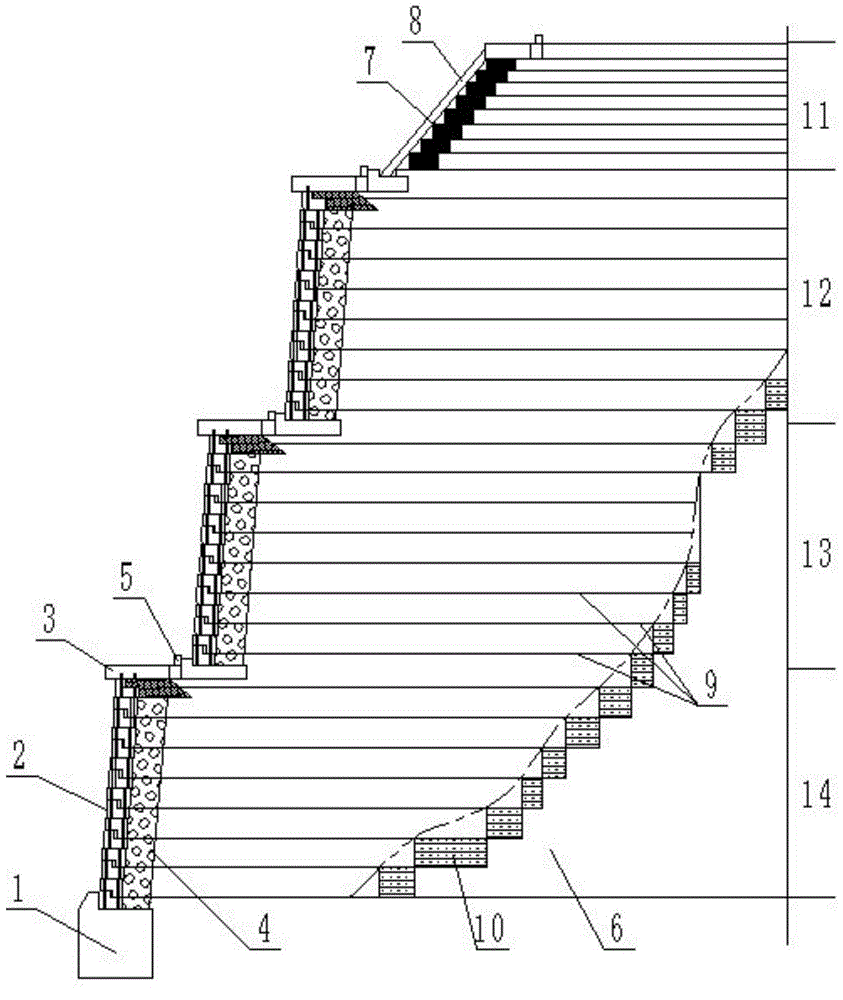

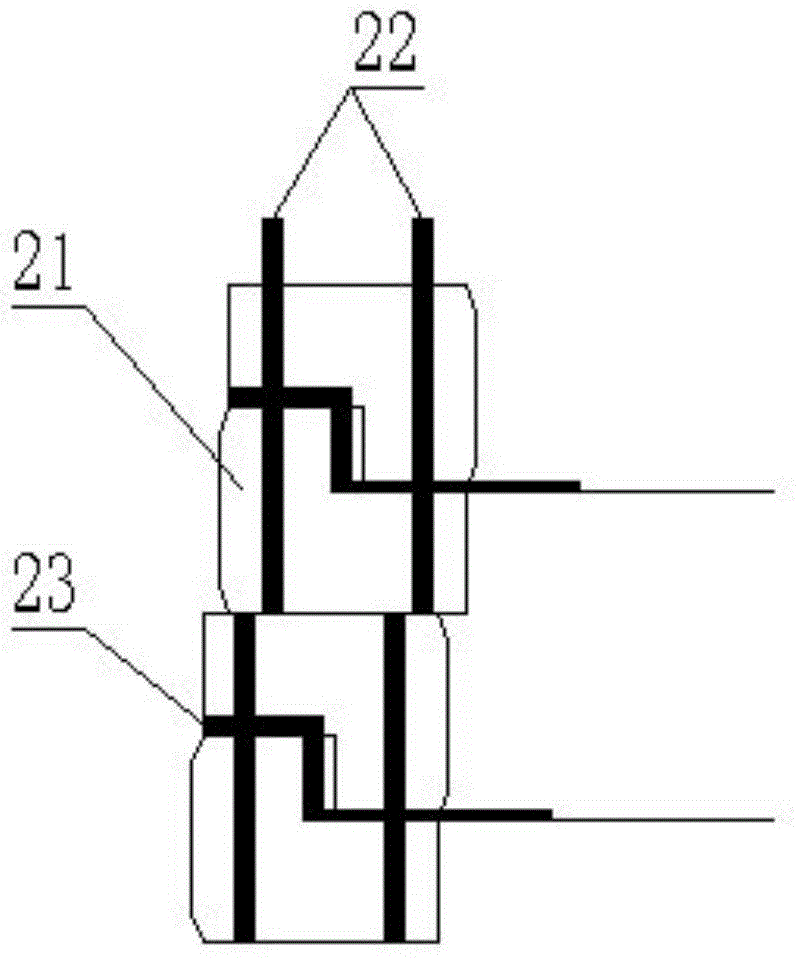

Ultrahigh integrated plastic-steel grid reinforced soil abutment retaining wall structure and construction method thereof

A technology of steel-plastic grid and construction method, which is applied in the direction of basic structure engineering, underwater structures, bridges, etc., and can solve problems such as multiple raw materials, manpower and time, large area occupied by reinforced soil, and increased construction costs. , to achieve the effects of shortening the construction period, convenient construction and large friction coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0061] Embodiment: The K4+615 bridge project of the west section of Pingba, Gui'an Avenue, Guizhou adopted the super-high integral steel-plastic grid reinforced soil abutment construction technology provided by the present invention, and the overall super-high reinforced soil abutment wall in the project The height reaches 32m. The specific construction is as follows:

[0062] Construction preparation: According to the model and specification of the overall steel-plastic grille on the drawing, the overall steel-plastic grille will be inspected according to the regulations after entering the site, and the breaking strength, elongation, single strip width, and single strip thickness will be randomly inspected for each batch. Hole size, joint stripping force and deflection rate; foundation trench excavation and compaction: excavate several foundation trenches arranged at the same height along the mountain 6 from top to bottom; prefabricated panel 2: panel 2 is prefabricated with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Longitudinal strength | aaaaa | aaaaa |

| Transverse strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com