Gas turbine blade with longitudinal crossed rib cooling structure

A technology of cooling structure and gas turbine, which is applied to the supporting elements of blades, machines/engines, mechanical equipment, etc., can solve the problem of weakening the heat exchange effect between the cooling airflow and the blade body, enhancing the life loss of turbine blades, and the utilization rate of cooling gas. Low problems, to achieve the effect of good overall cooling performance, simple structure, and improved utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

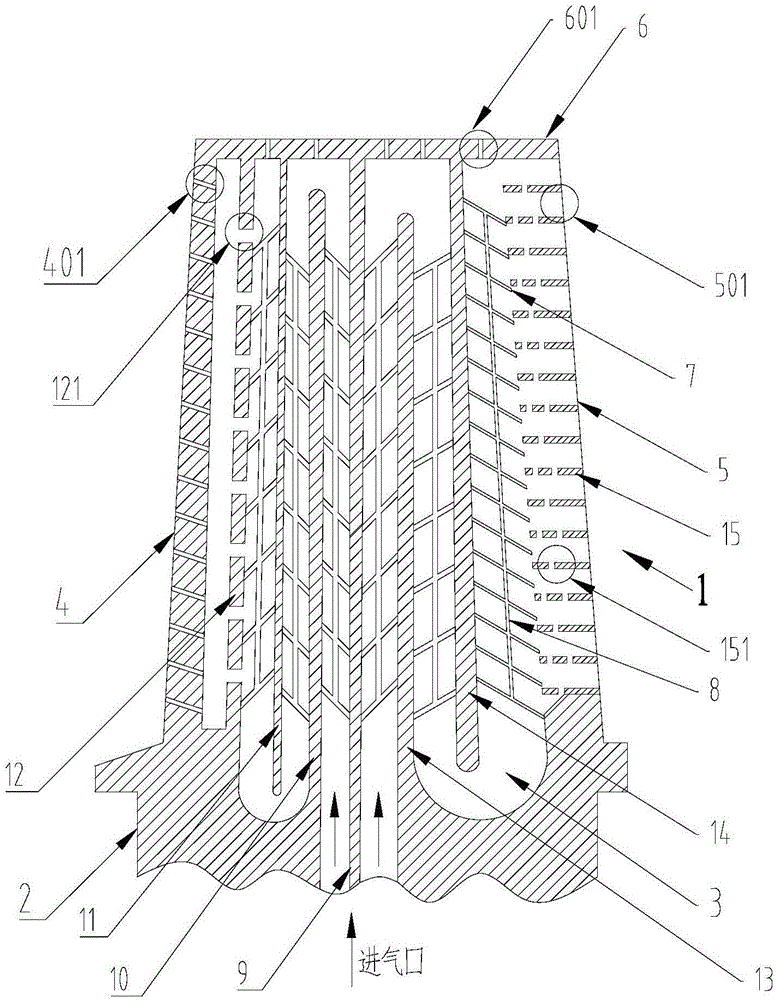

[0027] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0028] Such as figure 1 As shown, the present invention has a gas turbine blade with a longitudinally intersecting rib cooling structure, including an integrally formed airfoil 1 and a blade root platform 2, and a cooling chamber 3 is provided inside the airfoil 1, and the cooling chamber 3 is composed of The pressure surface and the suction surface of the airfoil 1, as well as the leading edge 4 and the trailing edge 5 are surrounded by a number of leading edge film cooling holes 401 on the leading edge 4, and a number of trailing edge holes 401 on the trailing edge 5. The air outlet hole 501, the top of the blade body 1 is provided with a top plate 6, the top plate 6 is provided with a number of blade top air film cooling holes 601, and the center of the blade root platform 2 is provided with an air inlet connected to it;

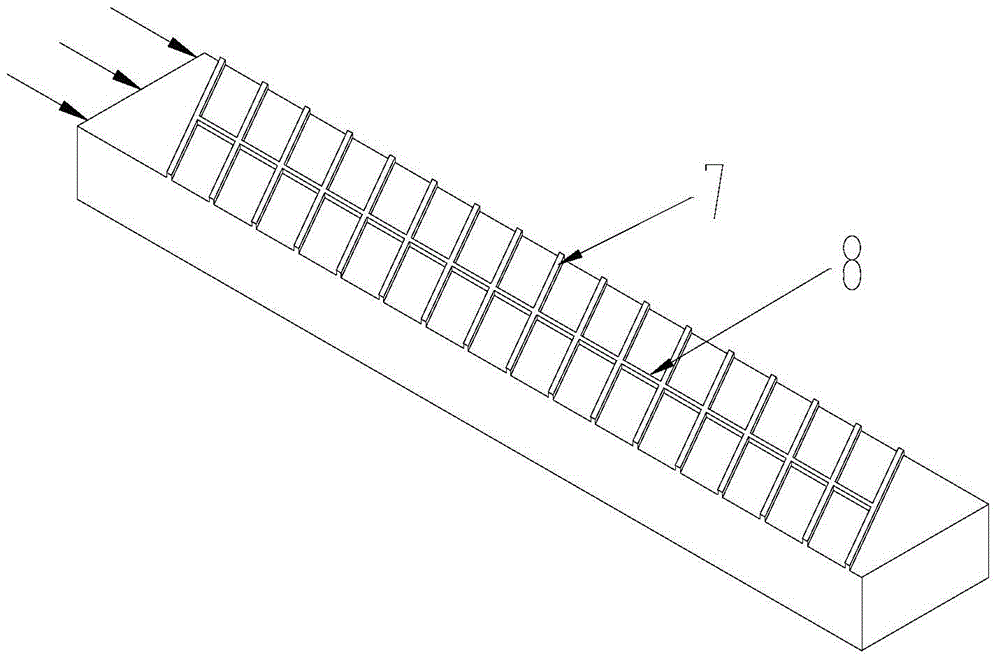

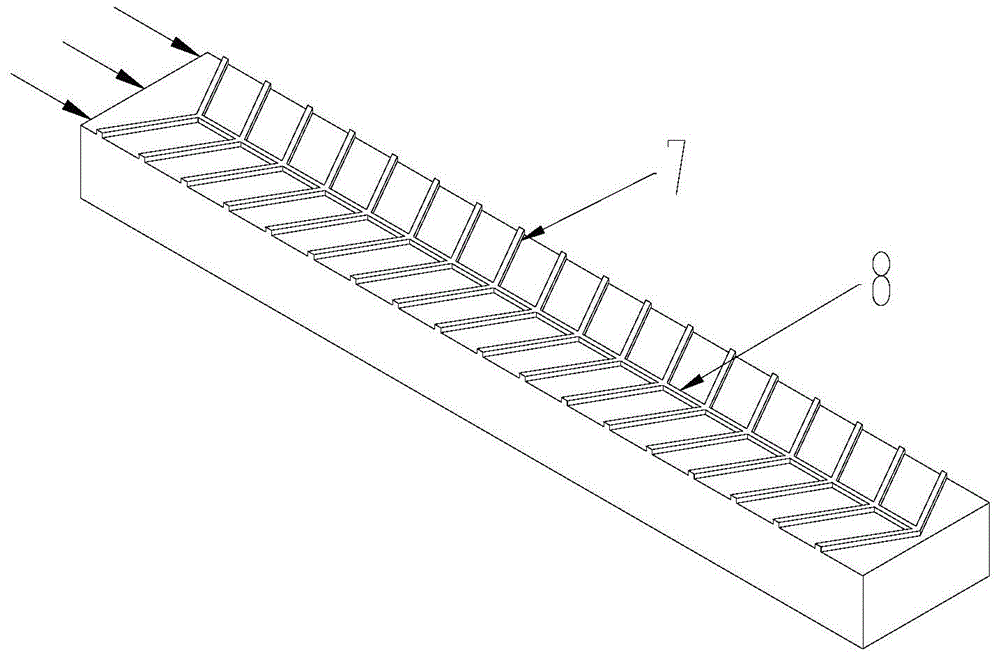

[0029] The inner surface of the pressure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com