Rotation type energy recovery device

An energy recovery device, a rotary technology, which is applied to fluid pressure actuation devices, engine seals, engine components, etc., can solve the problems of requiring a large rotational torque, difficulty in miniaturization of devices, and difficult practical commercial application value, etc. The effect of reducing operating noise, reducing rotational torque, and reducing drive power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Exemplary embodiments of the present invention are described below in conjunction with the accompanying drawings, which include various details of the embodiments of the present invention to facilitate understanding, and they should be regarded as exemplary only. Accordingly, those of ordinary skill in the art will recognize that various changes and modifications of the embodiments described herein can be made without departing from the scope and spirit of the invention. Also, descriptions of well-known functions and constructions are omitted in the following description for clarity and conciseness.

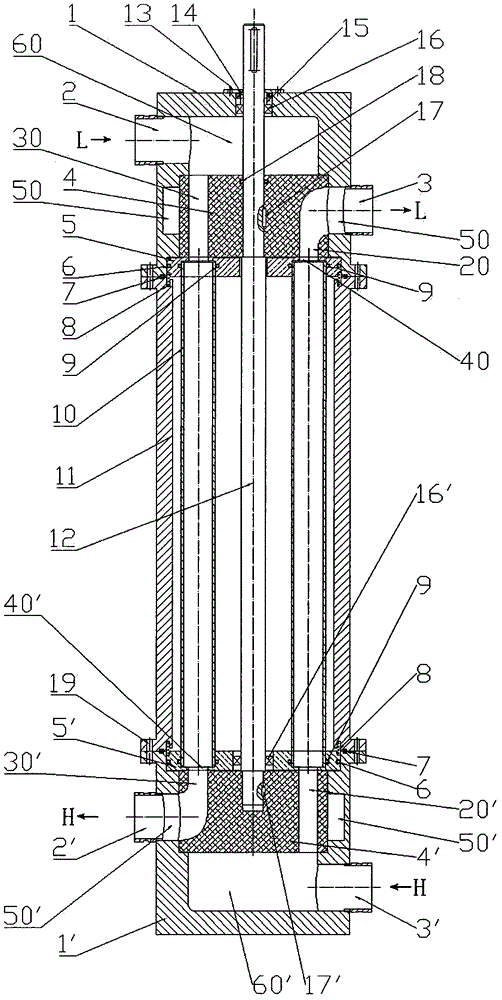

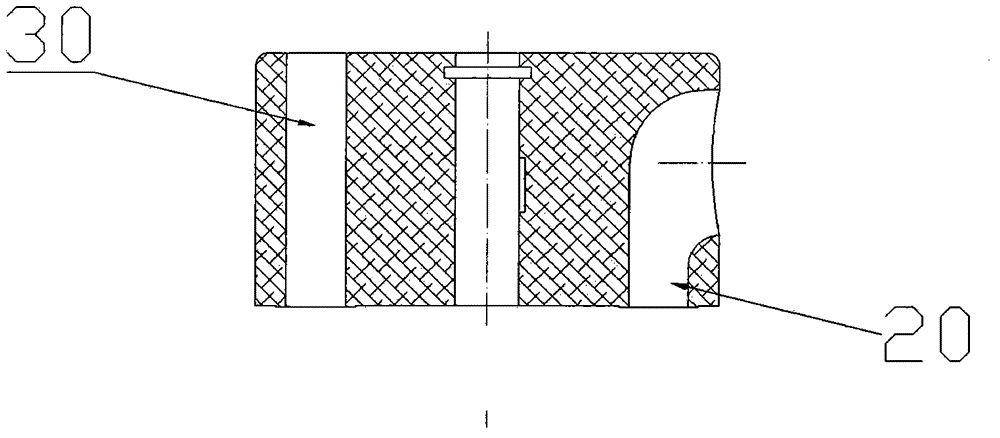

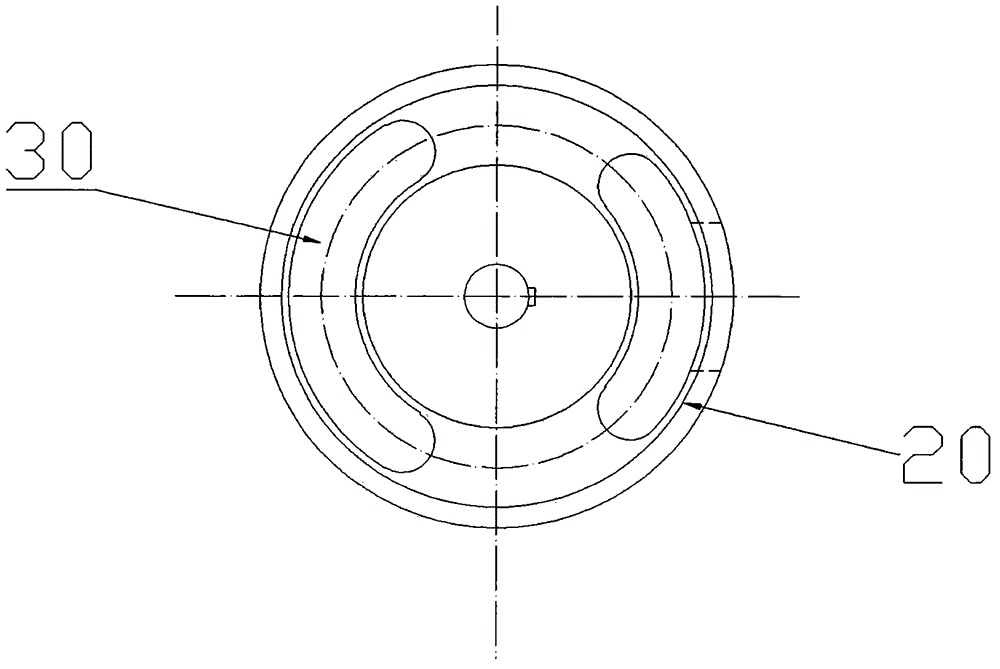

[0033] Refer to attached picture. It includes a rotating assembly, which includes: a drive shaft 12, a moving ring 15 for mechanical sealing sleeved outside the drive shaft, an upper flow distribution rotor 4, a lower flow distribution rotor 4', and the upper flow distribution rotor 4 is worn Insert the upper end of the drive shaft 12 and set a sealing ring 18 on the uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com