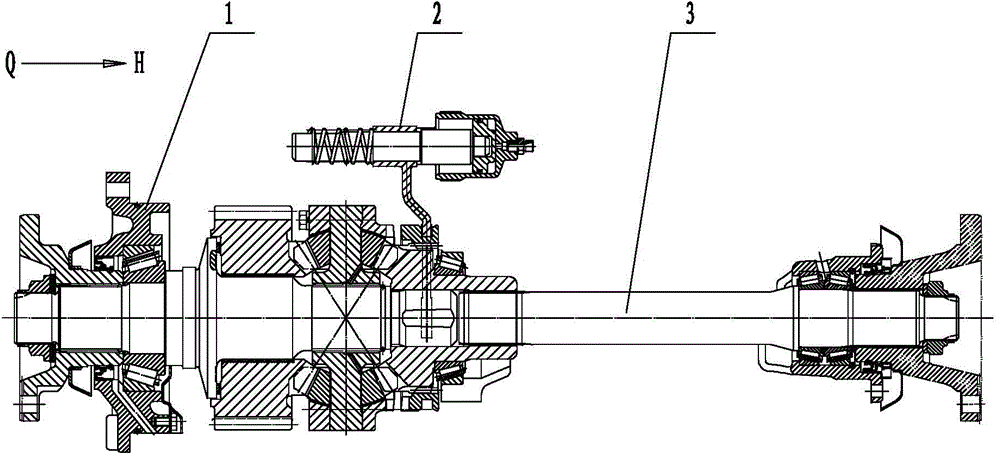

Postpositional open-type interaxle differential assembly

A differential and open technology, which is applied in the direction of differential transmission, transmission, transmission parts, etc., can solve the problems of difficult maintenance, poor lubrication, and far away from the oil pool, so as to facilitate the overall layout and reduce the Self-weight, the effect of increasing the loading capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

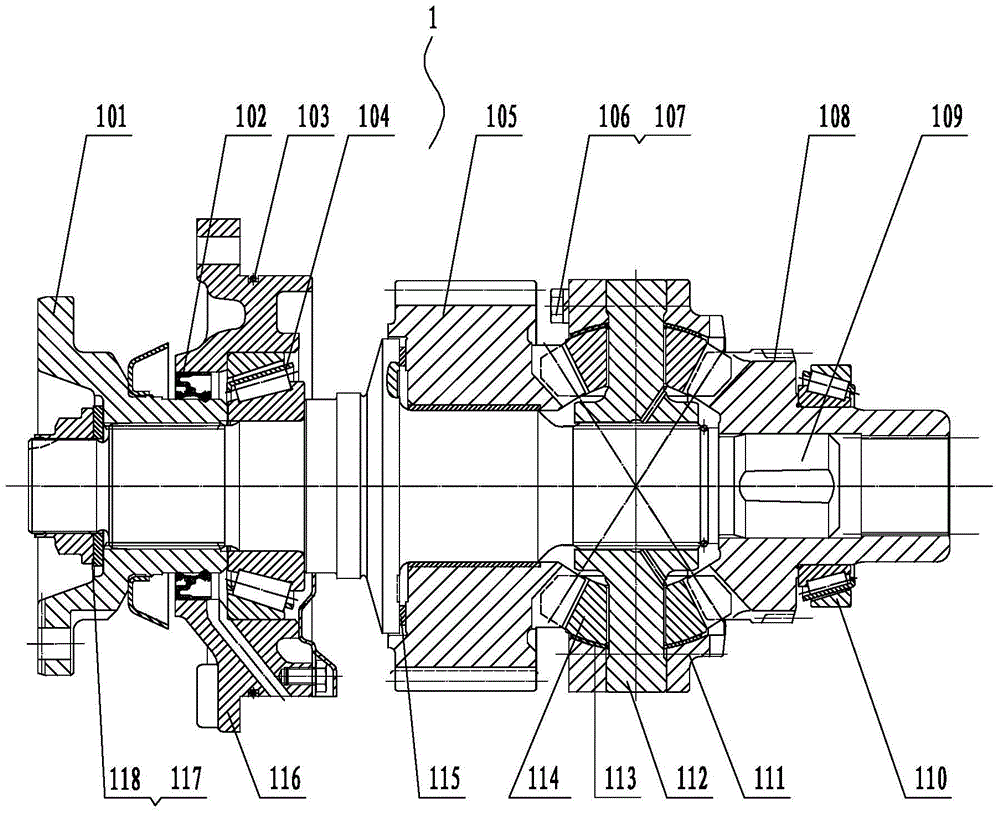

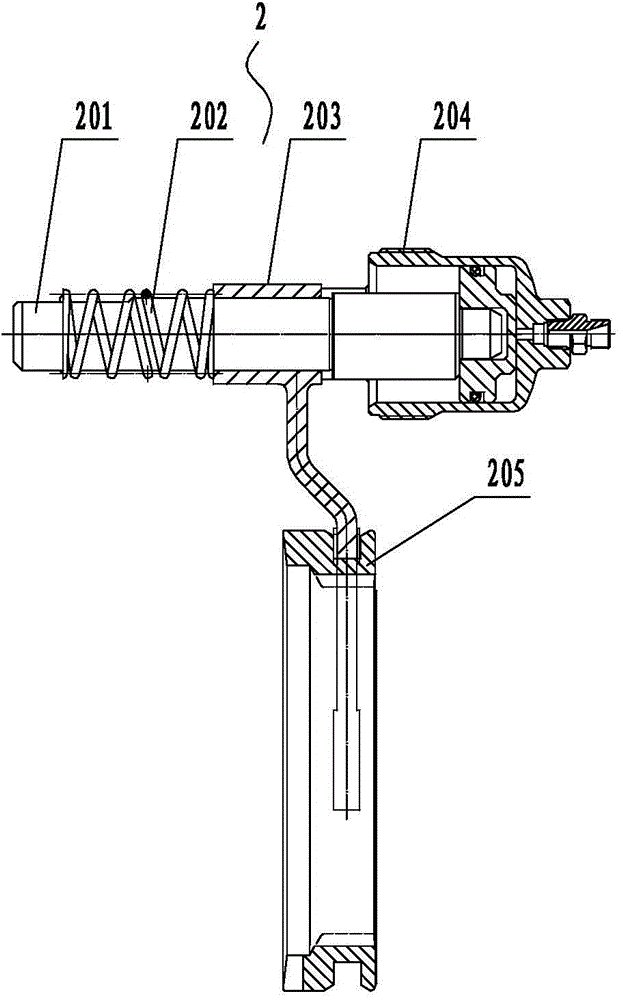

[0044] A rear open type inter-axle differential assembly, including an input shaft assembly 1, a differential lock assembly 2, and an output shaft assembly 3; the input shaft assembly 1 includes an input shaft 109, from front to back The input flange 101, bearing I 104, driving cylindrical gear 105, cross shaft 112, and rear half shaft gear 108 are sequentially arranged on the input shaft 109. The input flange 101 is locked by a fastener lock nut 117 and a washer 118. Close to the front end of the input shaft 109; the bearing I104 is installed in the bearing seat I116, the front end of the bearing seat I116 is connected to the rear end of the input flange 101 through the seal oil seal 102, and the bearing seat I116 is also installed with O Type ring 103; a thrust washer 115 is installed between the front end of the driving cylindrical gear 105 and the tapered step of the input shaft, and a planetary gear 114 is arranged on the cross shaft 112, and the planetary gear 114 is inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com