Ultrahigh molecular weight polyethylene steel lining pipe joint

A technology of ultra-high molecular weight and polyethylene, applied in the direction of pipes/pipe joints/fittings, flange connections, passing components, etc., can solve the problem that the pipe cannot withstand negative pressure well, the conveying system cannot run safely and reliably, Problems such as poor sealing performance of pipe connection, to achieve the effect of improving the sealing performance of pipe connection, simple manufacturing process and good sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0021] According to user needs, according to The diameter, pressure bearing capacity and service environment of the steel liner can be designed and manufactured with various ultra-high molecular weight polyethylene steel liner joints.

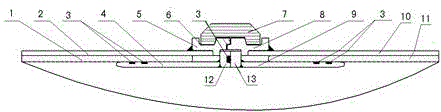

[0022] The present invention as figure 1 As shown, the UHMWPE Steel Liner Fittings , including joint inner core, joint outer core, O-ring, joint slot, quick clamp and locking bolt. The joint inner core is composed of joint inner core I and joint inner core II, and the joint outer core is composed of joint outer core I and joint outer core II. Ⅱ On the two ends of the butt joint surface, place it in the inner cavity of the pipe through the oil cylinder, and The inner wall of the ultra-high molecular weight polyethylene pipe is laminated, A flange I and a flange II are respectively provided at the ends of the two corresponding butt joint surfaces of the joint inner core I and the joint inner core II, and the butt joint surfaces of the two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com