Housing for induction cooker or radiant cooker

A technology of electric ceramic cooker and induction cooker, applied in the direction of stove/stove base, etc., can solve the problems of poor structural strength, poor visual effect, poor oil stain resistance, etc., to improve aesthetics and coordination, highlight practical value, excellent Antibacterial and mildew proof effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

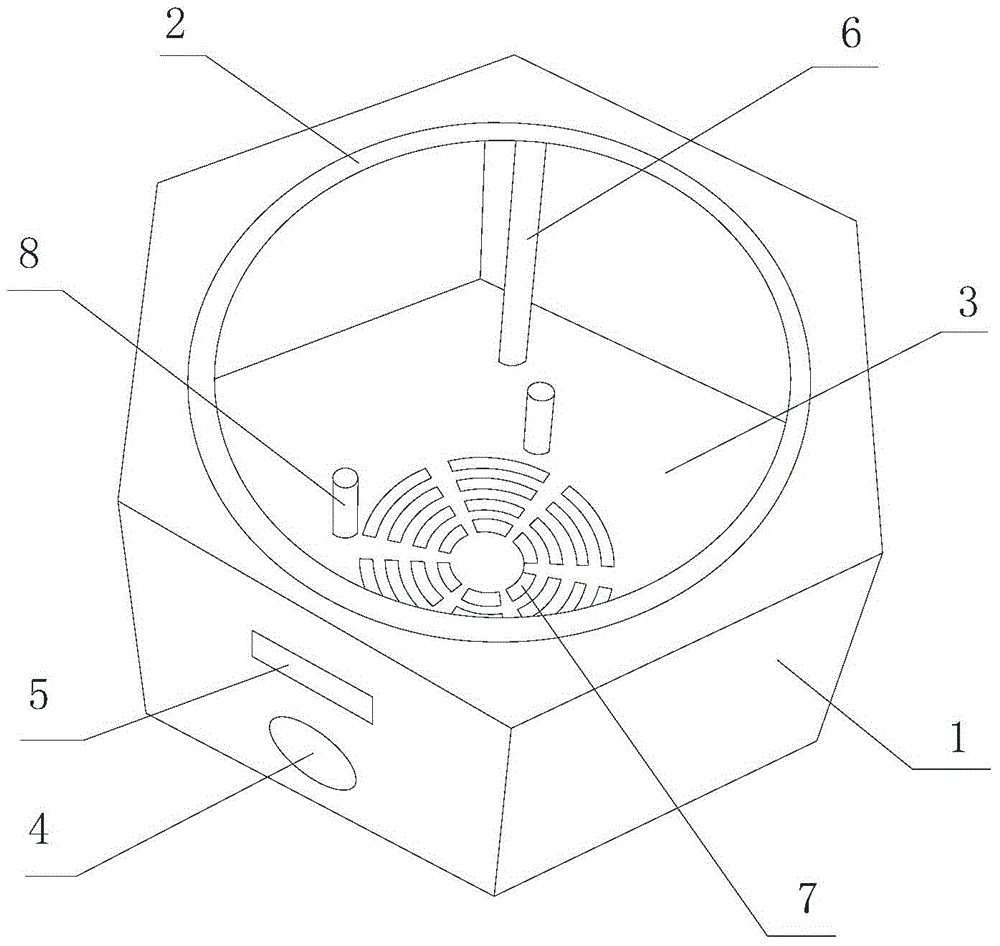

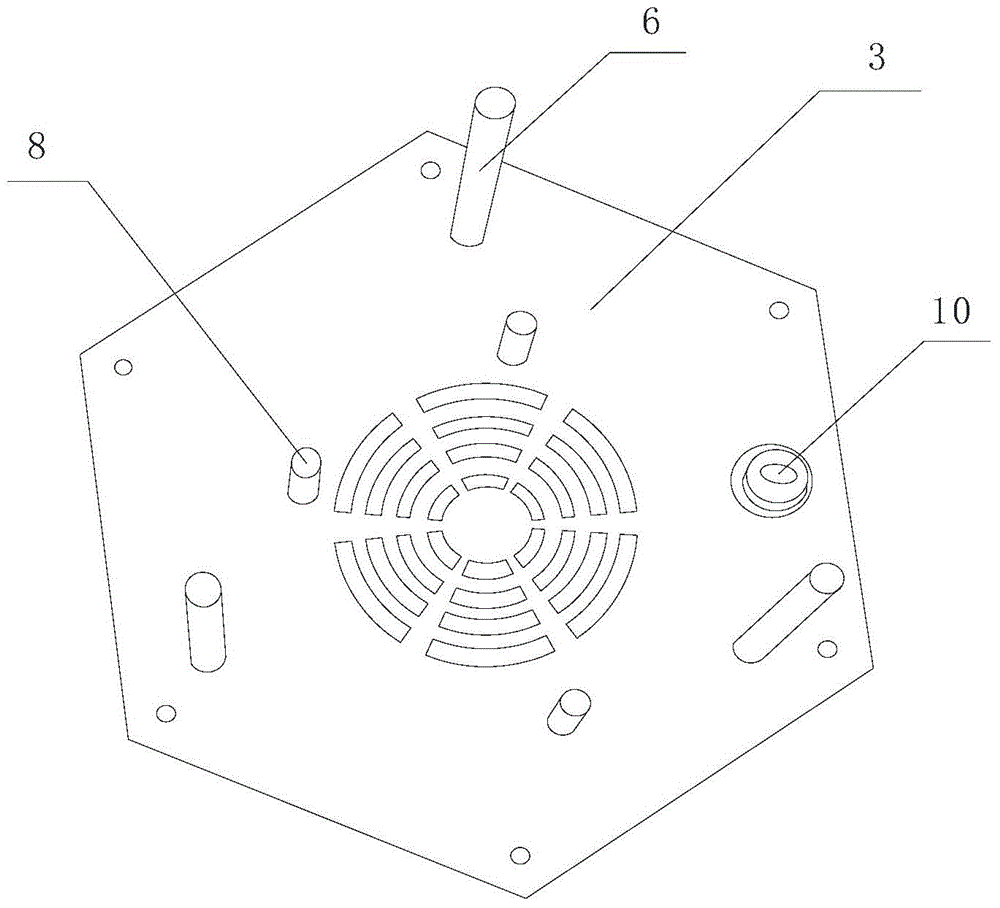

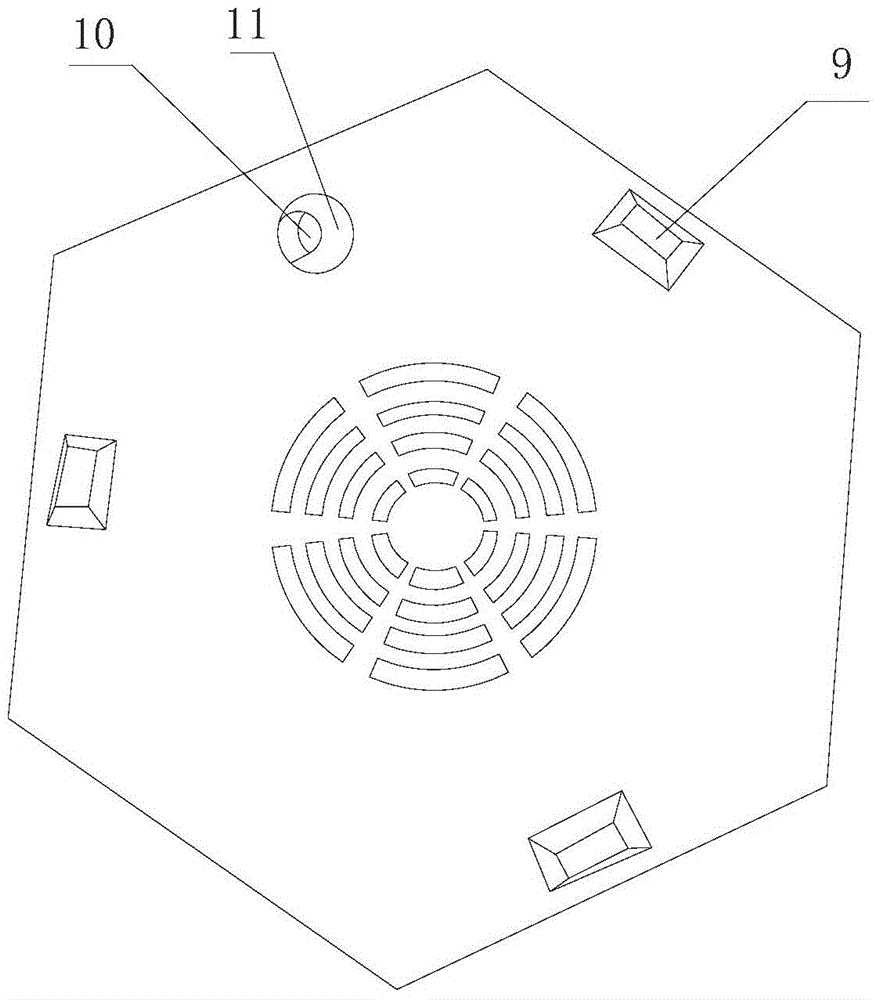

[0037] Such as figure 1 , figure 2 As shown, a shell frame for an electric ceramic stove includes: an integrally formed main body 1 , a panel mounting ring 2 formed on the upper part of the main body 1 , and a lower cover assembly 3 provided at the bottom of the main body 1 . Wherein, the main body 1 and the lower cover assembly 3 are formed by metal die-casting, and the surfaces of the main body 1, the panel mounting ring 2 and the lower cover assembly 3 are coated with a ceramic crystal layer whose color is consistent with that of the kitchen countertop.

[0038] In the present embodiment, the preferred ceramic crystal layer is made by spraying the ceramic crystal coating on the metal surface by spraying process; the ceramic crystal coating is an inorganic nano-scale coating, comprising by weight: aluminum silicate: 30 parts; nano-titanium dioxide : 10 parts; Pigment: 10 parts; Leveling agent: 1 part; Anti-settling agent: 1 part; Brightening agent: 1 part. Preferably, the...

Embodiment 2

[0042] A shell frame for an electric ceramic furnace provided in this embodiment is basically the same in structure as in Embodiment 1, the difference is that:

[0043] 1. The shape of the main body is a pentagonal prism, and the number of the support columns is five.

[0044] Two, the ceramic crystal coating comprises by weight:

[0045] Aluminum silicate: 70 parts;

[0046] Nano titanium dioxide: 40 parts;

[0047] Pigment: 40 parts;

[0048] Leveling agent: 5 parts;

[0049] Anti-sedimentation agent: 5 parts;

[0050] Brightening agent: 20 parts.

Embodiment 3

[0052] A shell frame for an electric ceramic furnace provided in this embodiment is basically the same in structure as in Embodiment 1, the difference is that:

[0053] 1. The shape of the main body is an octagonal prism, and the number of the supporting columns is eight.

[0054] Two, the ceramic crystal coating comprises by weight:

[0055] Aluminum silicate: 40 parts;

[0056] Nano titanium dioxide: 30 parts;

[0057] Pigment: 20 parts;

[0058] Leveling agent: 3 parts;

[0059] Anti-sedimentation agent: 3 parts;

[0060] Brightening agent: 10 parts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com