Long-distance general-circulation graded heat supply system

A heating system, remote technology, applied in heating systems, hot water central heating systems, household heating, etc., can solve the problems of wasting energy and labor costs, high return water temperature, small heating area, etc., and achieve reduction Effects of pollution, rapid heating of heat source, and large heating area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

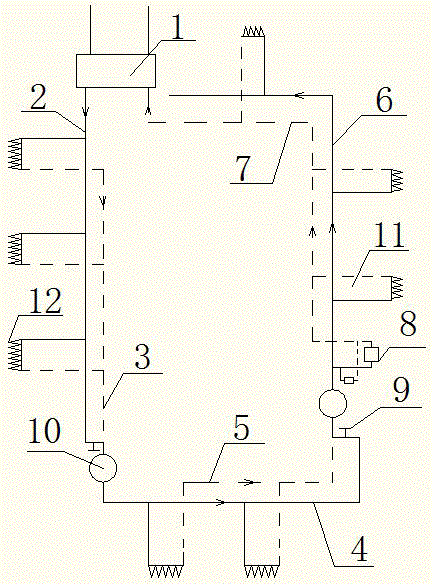

[0016] Accompanying drawing is a kind of specific embodiment of the present invention. This embodiment includes a power plant waste heat center heat exchange station 1, the power plant waste heat center heat exchange station 1 is connected to a primary heat supply pipeline 2, a primary heat supply pipeline 2 is provided with a primary return water pipeline 3, and the primary return water pipeline 3 is connected to a The secondary heating pipeline 4 is provided with a secondary return water pipeline 5 beside the secondary heating pipeline 4, and the secondary return water pipeline 5 is connected with a tertiary heating pipeline 6, and a tertiary return pipeline is arranged beside the tertiary heating pipeline 6. Water pipeline 7, the end of the third-level return water pipeline 7 is connected to the heat exchange station 1 of the waste heat center of the power plant, the third-level heat supply pipeline 6 is connected with several heat source units 8 in turn, the first-level hea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com