Intelligent automatic test system and method

An automatic test system and automatic test technology, applied in the direction of measuring electricity, measuring devices, measuring electrical variables, etc., can solve the problems of inconsistent test data format, low test work efficiency, and dependence on personal ability, and achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

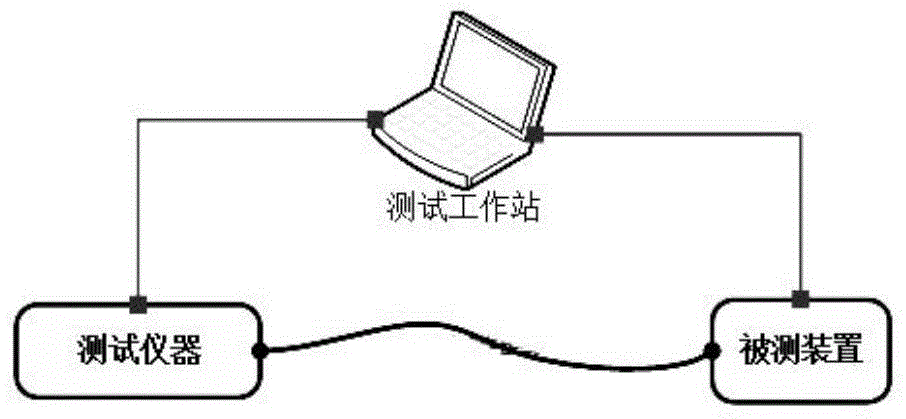

[0054] Such as figure 1 As shown, the intelligent automatic test hardware of the present invention includes a test instrument, a device under test and a test workstation. The test instrument and the device under test are connected to form a test loop through the test connection line, and the test instrument, the test workstation and the device under test are connected to form a test closed loop through their respective communication lines; the intelligent automatic test software system of the present invention is installed in the test workstation.

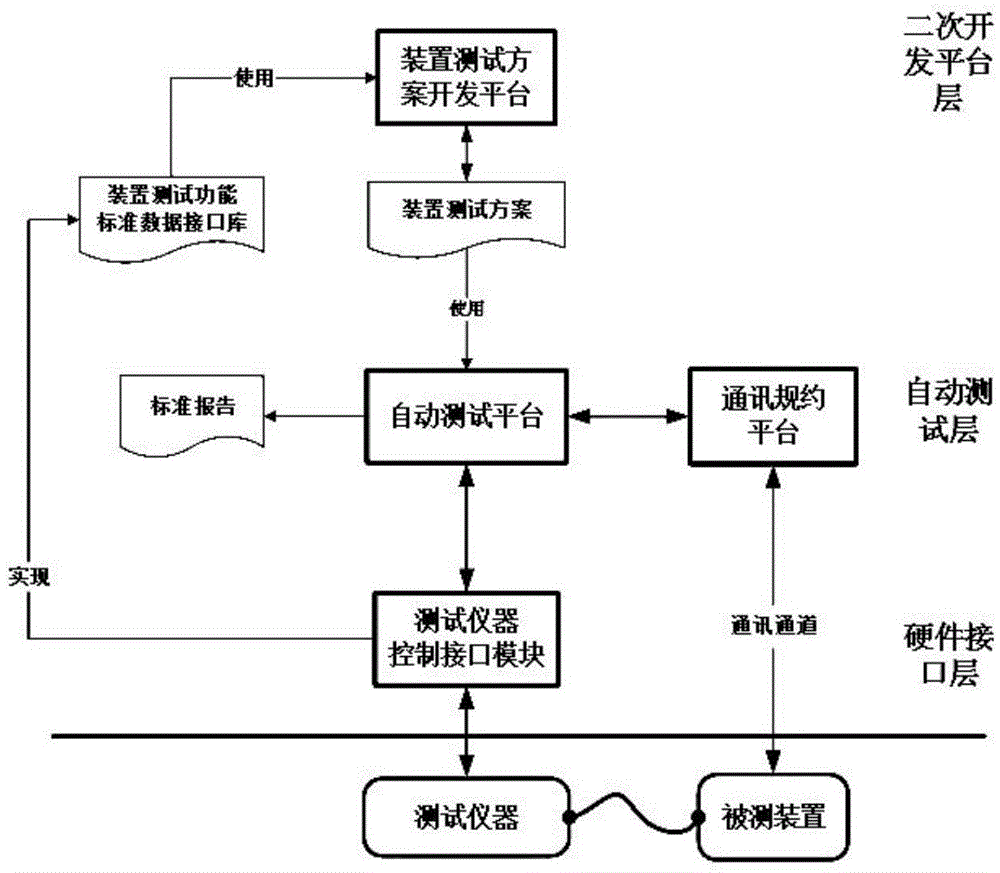

[0055] Such as figure 2 As shown, the intelligent automatic test system software has a three-layer structure: the standard secondary development platform layer, the automatic test layer, and the test instrument hardware interface layer. The standard secondary development platform layer includes a device test plan, a device test function standard data interface library, and a device test plan development platform. The standard se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com