Real-time data acquisition system of wheat processing factory

A real-time data acquisition, data acquisition and processing technology, applied in the direction of comprehensive factory control, comprehensive factory control, general control system, etc., can solve the problems of unused equipment and production data, large data flow, low production efficiency, etc., to achieve The management and monitoring of the whole life cycle, the effect of efficient production and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with drawings and embodiments.

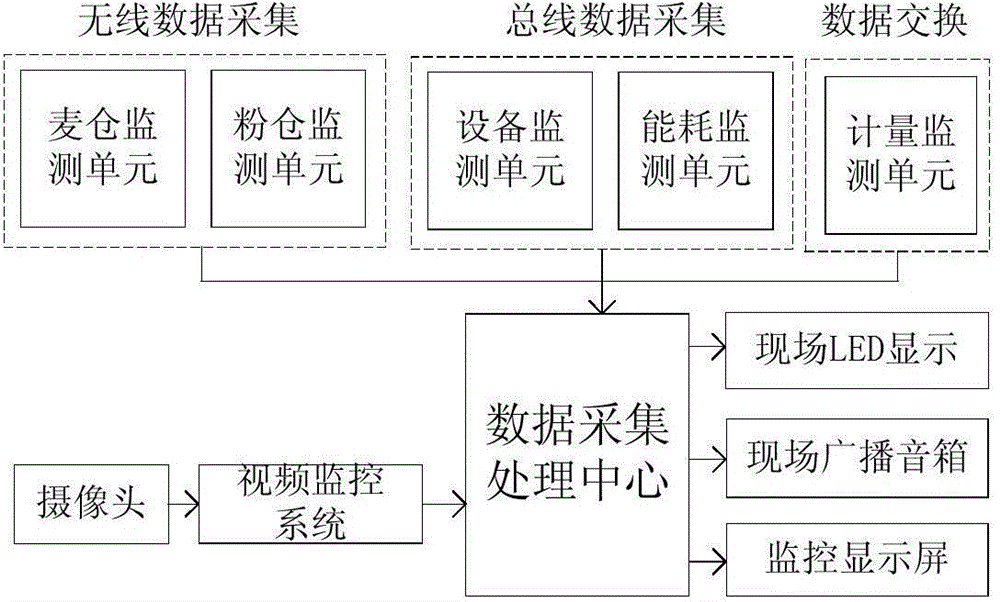

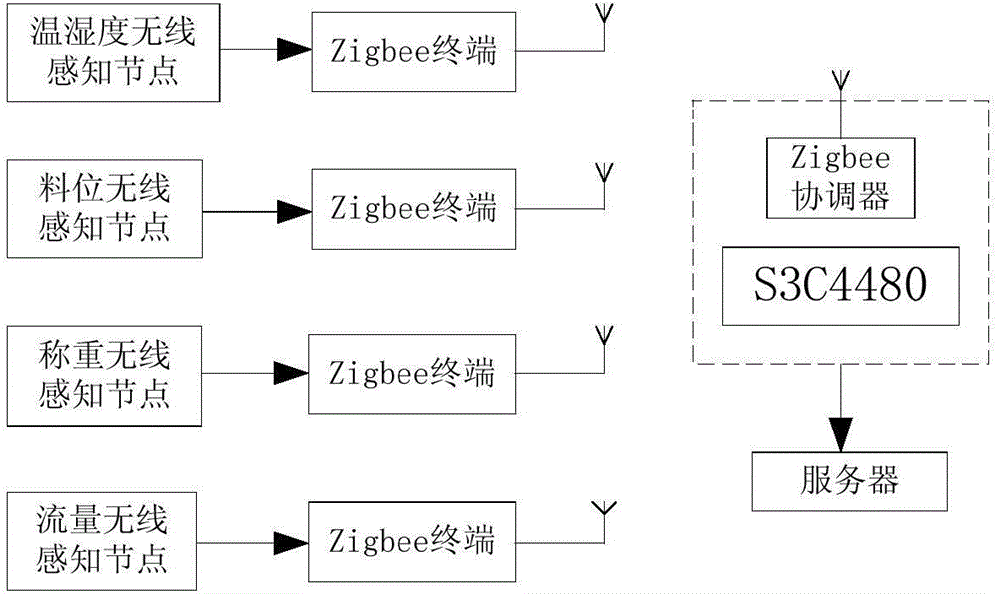

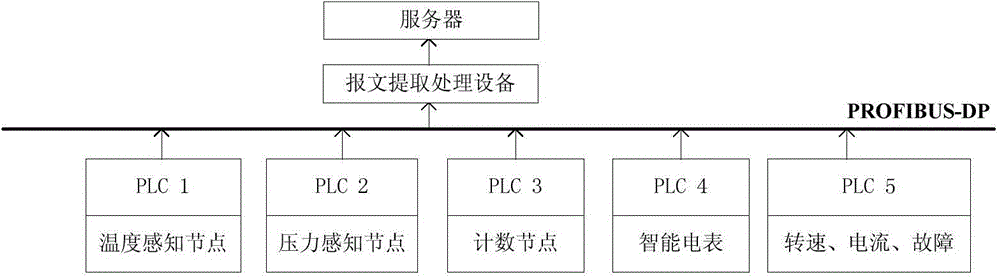

[0021] Such as figure 1 As shown, the present invention includes: a wheat bin monitoring unit, a powder bin monitoring unit, an equipment monitoring unit, an energy consumption monitoring unit and a metering monitoring unit. The data acquisition part of the wheat bin and powder bin monitoring unit includes temperature wireless sensing nodes, humidity wireless sensing nodes, material level wireless sensing nodes, weighing wireless sensing nodes, and flow wireless sensing nodes respectively located in the wheat bins and powder bins. Respectively connect respective Zigbee terminals, said Zigbee terminals communicate wirelessly with Zigbee coordinator, and Zigbee coordinator connects data collection and processing center, such as figure 2 ; This part is wireless data collection. The equipment monitoring unit and the energy consumption monitoring unit include a temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com