Method for preparing high-performance NdFeB magnet through grain boundary diffusion Dy-Cu alloy

A technology of grain boundary diffusion and neodymium iron boron, applied in the direction of magnetic objects, magnetic materials, inorganic materials, etc., can solve the problems of adhesion layer defects, unfavorable grain boundary diffusion technology promotion and application, and low efficiency of grain boundary diffusion heat treatment. The effect of increasing depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

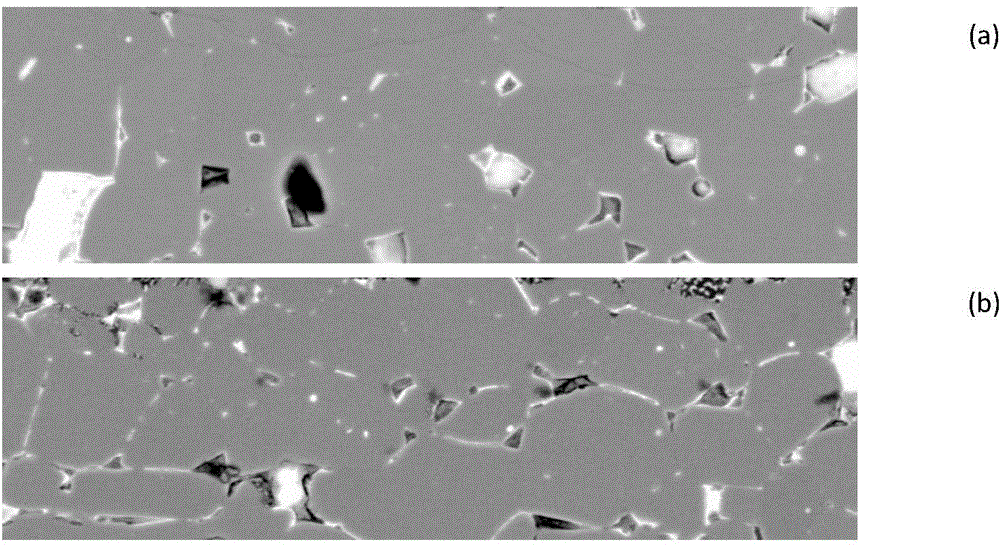

[0022] 8mm thick 38H magnet surface covered with Dy70Cu30 (atomic percent) ingot grain boundary diffusion heat treatment

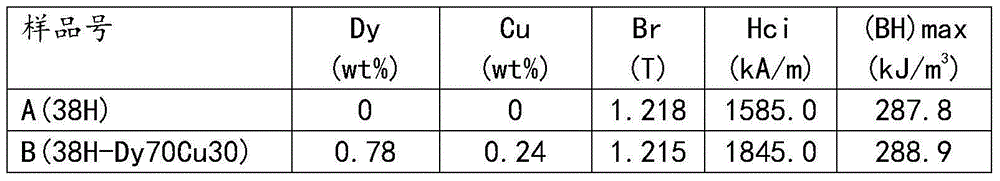

[0023] Select a 38H commercial magnet, mark it as sample A, and process it into a sample with a size of 20mm×20mm×8mm. A Dy70Cu30 (atomic percent) alloy ingot with a thickness of 300 μm was prepared by the quick-setting thin slice ingot process, and it was directly covered around the A magnet, and the sample was placed in the furnace and evacuated to (3-5)×10 -3 Pa, start rapid heating to 800°C, keep it warm for 2h, and then conduct heat treatment at 500°C / 2h, this sample is marked as B sample. Table 1 shows the Dy / Cu content and magnetic performance parameters of samples A and B. It can be seen that the Dy / Cu diffusion effect of this method of grain boundary diffusion heat treatment is also very good, the coercive force is significantly improved, and the change in remanence is small.

[0024] Table 1 Dy / Cu content and magnetic properties of 8 mm thick 3...

Embodiment 2

[0027] 6mm thick N40 magnet surface covered with Dy65Cu35 (atomic percent) ingot grain boundary diffusion heat treatment

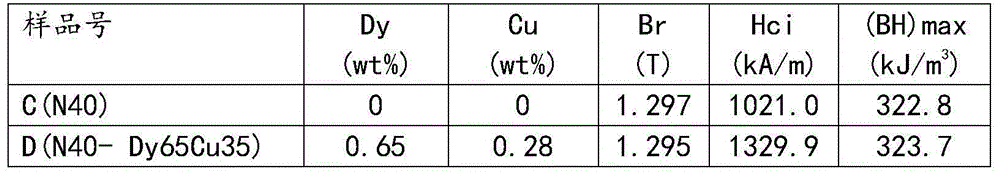

[0028] Select an N40 commercial magnet, mark it as sample C, and process it into a sample with a size of 20mm×20mm×5mm. Vacuum melting Dy65Cu35 (atomic percent) alloy ingots, coarsely crushed into 1-3mm particles, covering around the C magnet, placing the sample in the furnace, and vacuuming to (3-5)×10 -3 Pa, start rapid heating to 860°C, keep it warm for 1.5h, and then perform annealing heat treatment at 500°C / 2h, this sample is D sample. Table 2 shows the Dy / Cu content and magnetic performance parameters of samples C and D. It can be seen that the Dy / Cu diffusion effect of this method of grain boundary diffusion heat treatment is very good, the coercive force is significantly improved, and the change of remanence is small.

[0029] Table 2 Dy / Cu content and magnetic properties of samples after N40 surface covering Dy65Cu35 (atomic percentage) ingot di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com