Vermicelli-jelly sheet production line

A production line and vermicelli technology, applied in the field of food processing equipment, can solve problems such as a large number of large labor, complicated drying procedures, etc., and achieve the effects of water saving, compact design and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

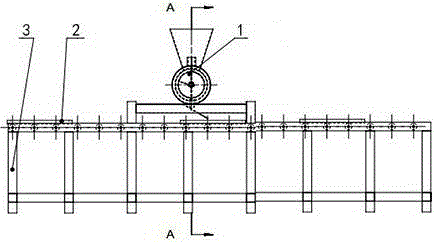

[0011] Embodiment 1: as figure 1 As shown: the forming component 1 is installed above the vermicelli forming line 3, and the drying board 2 is transported on the vermicelli forming line 3 in the interlayer between the vermicelli forming line 3 and the forming component 1.

Embodiment 2

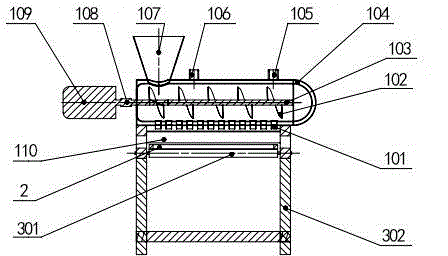

[0012] Embodiment 2: as figure 2 Shown: on the basis of the technical solution described in Embodiment 1, the molding assembly 1 includes a deflector 110, a discharge port 101 above the deflector 110, a hollow molded container 104 above the discharge port 101, and a hollow molded container 104 The inner rotary blade 102, the main shaft 103 that drives the rotary blade 102, the motor 109 that drives the main shaft 103, the coupling 108 that connects the motor 109 and the main shaft 103, the steam outlet 105 at the rear of the hollow forming container 104, the front of the hollow forming container 104 The steam inlet 106 at the top and the feed port 107 at the front of the hollow forming container 104 can realize the automatic molding of vermicelli vermicelli.

Embodiment 3

[0013] Embodiment 3: as figure 2 Shown: on the basis of the technical solution described in embodiment 2, the main shaft 103 installed inside the hollow forming container 104 and the rotary blade 102 installed on the main shaft 103 adopt rotary molding, which reduces the waste of raw materials and reduces the production cost of products.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com