Method for preparing an artificial stone with decorative patterns

A technology of artificial stone and patterns, which is applied in the field of preparation of patterned artificial stones, can solve problems such as the inability to realize the diversification of artificial stone colors and textures, and achieve the effect of superior appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1 A kind of preparation method of pattern artificial stone, its raw material weight ratio is as follows:

[0027] Slurry: 15 parts of unsaturated polyester resin, 1 part of cobalt naphthalate, 1 part of methyl ethyl ketone peroxide, 0.3 part of organosilane coupling agent, 0.3 part of colorant, 60 parts of aluminum hydroxide. Various raw materials are mixed evenly to prepare slurry.

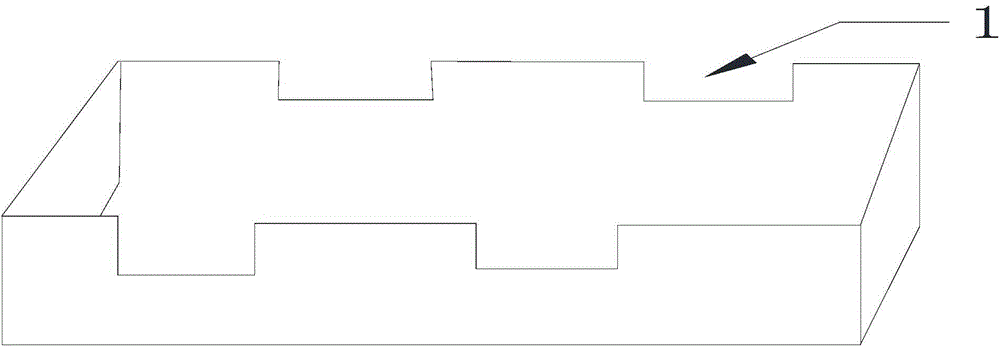

[0028] Such as figure 1 As shown, the slurry is poured into the square trough placed above the mold; under the condition of vacuum and negative pressure, the slurry overflows into the mold through the square teeth 1 on the square trough to complete the texture setting.

Embodiment 2

[0029] Embodiment 2 A kind of preparation method of pattern artificial stone, its raw material weight ratio is as follows:

[0030] Slurry: 40 parts of polymethacrylate, 1 part of accelerator, 1 part of curing agent, 1 part of organic silane coupling agent, 1 part of colorant, 60 parts of quartz powder.

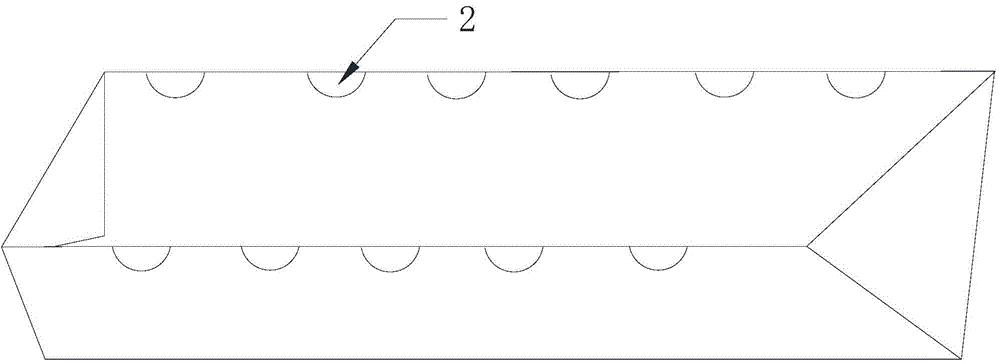

[0031] Such as figure 2 , the slurry is poured into the triangular trough placed above the mold, and after the slurry overflows from the arc-shaped mouth 2 on the triangular trough and pours into the mold, the remaining amount of the triangular trough is no more than one-third of the total amount of slurry The remaining slurry; the remaining slurry is poured into the mold after the vacuum negative pressure ends, and then the vacuum negative pressure completes the shaping.

Embodiment 3

[0032] Embodiment 3 A kind of preparation method of pattern artificial stone, its raw material weight ratio is as follows:

[0033] Slurry: 50 parts of polymethacrylate, 1 part of accelerator, 1 part of curing agent, 1 part of titanate coupling agent, 2 parts of coloring agent, 50 parts of aluminum hydroxide powder.

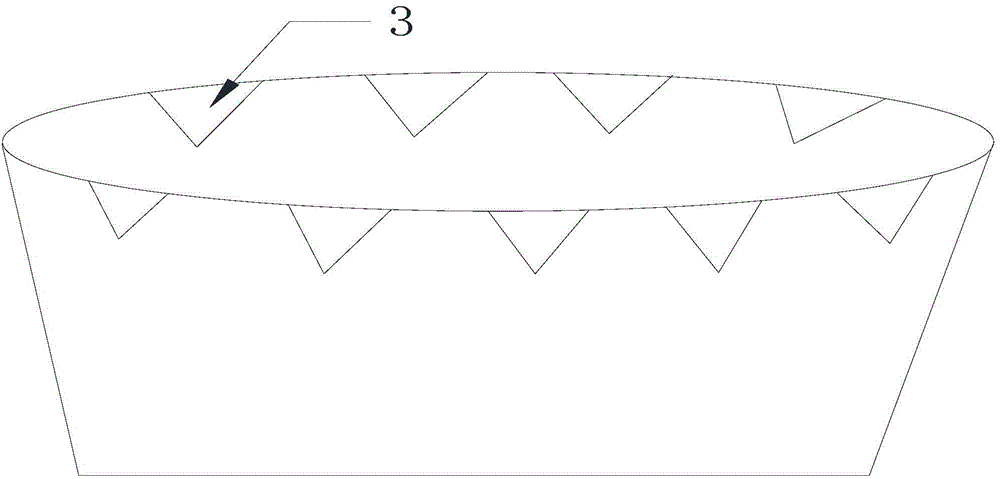

[0034] Such as image 3 As shown, the slurry is poured into the pot-shaped trough placed above the mold, and after the slurry overflows from the arc-shaped mouth 3 on the triangular trough and pours into the mold, the remaining amount of the pot-shaped trough is no more than the total amount of slurry One-third of the remaining slurry; the remaining slurry is poured into the mold under vacuum and negative pressure conditions to complete the pattern setting.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com