Steaming-boiling bag capable of pre-storing food for microwave oven

A technology for microwave ovens and cooking bags, which is applied in the directions of packaging food, packaging item types, bags, etc., can solve the problems of food not being well preserved, leaking to the outside, and troublesome for consumers to operate, and achieve the effect of prolonging the shelf life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

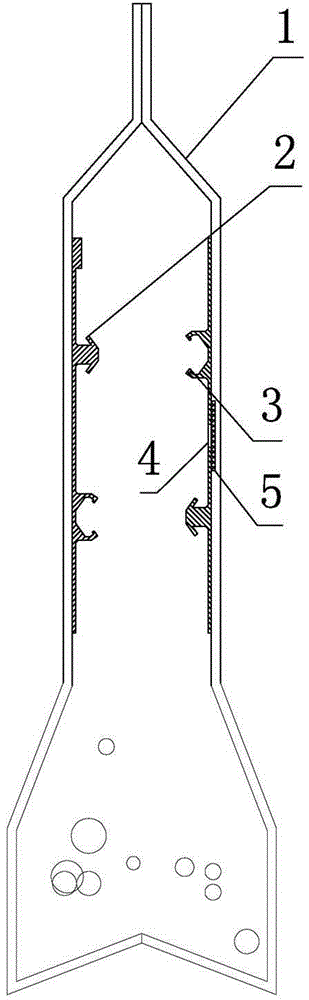

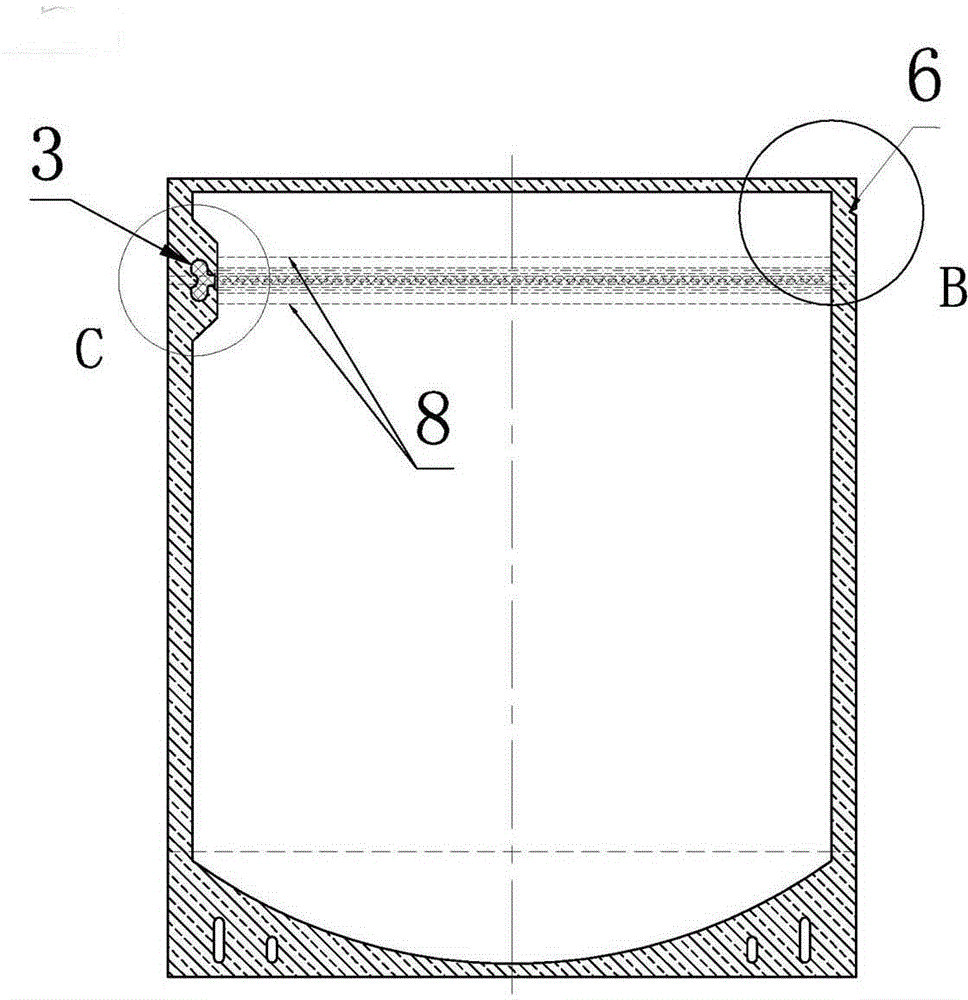

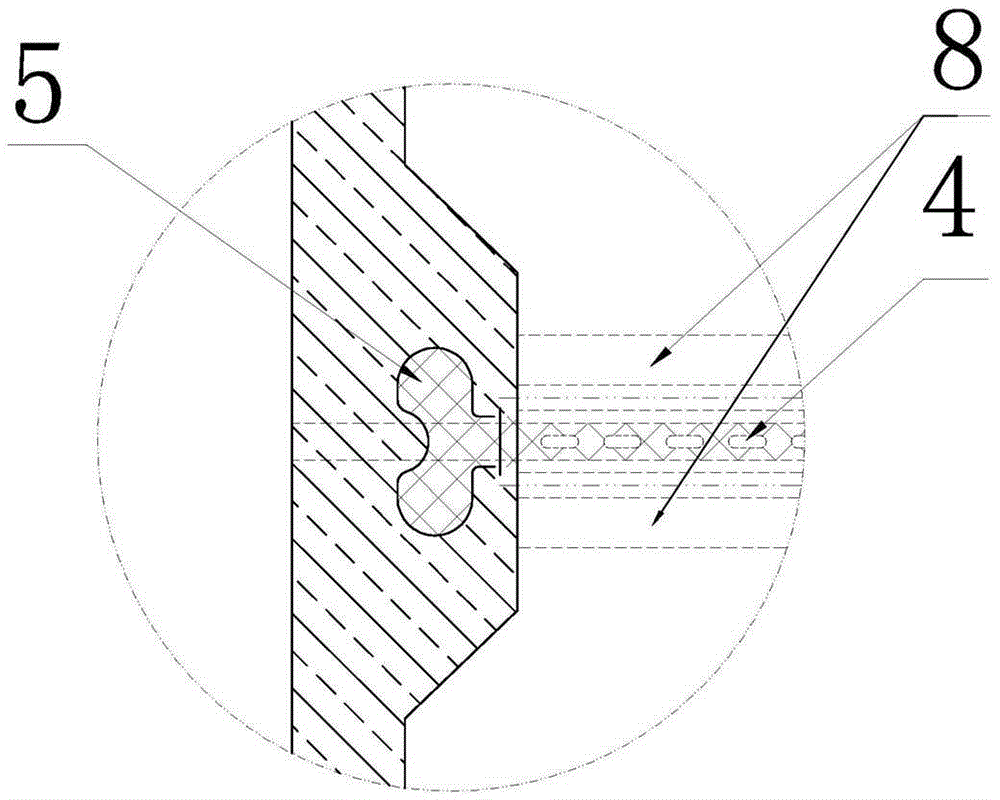

[0021] like Figure 1-4 As shown, the microwave retort bag that can be preloaded with food and the microwave retort bag that can be preloaded with food are provided with two rows of interlocking male strips 2 and female grooves 3 at opposite positions in the bag body 1, and the male strips 2 and female grooves 3 are respectively Two pieces of film are connected to the bag body 1, at least one vent hole 4 is opened on the film between the male strip 2 and the female groove 3 on one side of the bag body 1, and a tear strip is superimposed on the bag body 1 above it 5. After the tear strip 5 is torn, the internal air vent 4 can leak out. The upper bag body 1 of the zipper is provided with a laser line 7, and the end of the laser line 7 opens a tear 6, which is torn along the laser line 7 from the tear 6, and the contents can be taken out.

[0022] The opening strength of the zipper 8 above the air vent is 80N / 50mm, and the opening strength of the zipper below the air vent is 30N...

Embodiment 2

[0025] like Figure 5 and 6 As shown in the microwave retort bag that can be preloaded with food, there are two rows of interlocking male strips 2 and female grooves 3 at opposite positions in the bag body 1, and the male strips 2 and female grooves 3 are bonded together by ultrasonic waves through two films. On the bag body 1, at least one vent hole 4 is opened on the film between the strips on one side of the bag body 1, and two laser lines are opened on the bag body 1 above it and on both sides of the vent hole 4 7. The bag body 1 in the middle part of the laser line 7 can be torn along the laser line to leak out the internal exhaust hole 4. The upper bag body 1 of the zipper is provided with a laser line 7, and the end of the laser line 7 opens a tear 6, and is torn along the laser line from the tear, so that the contents can be easily taken out. The opening strength of the zipper above the vent hole is 80N / 50mm, and the opening strength of the zipper below the vent hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com