Electric flocculation and air floatation combined continuous microalgae harvesting device and method

An electrocoagulation air flotation and harvesting device technology, applied in the biological field, can solve the problems of microalgae harvested water pollution, non-continuous production, high flocculation dosage, etc., and achieves convenience for large-scale production, improved electrolysis efficiency, and low price Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with accompanying drawing.

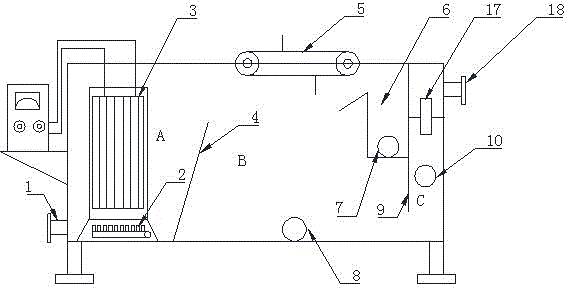

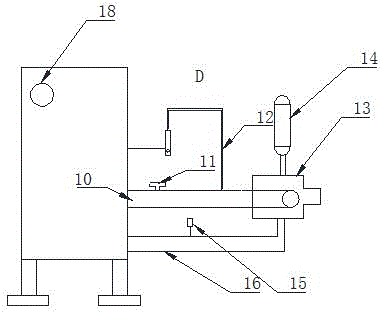

[0026] The device of the present invention is as attached figure 1 And attached figure 2 shown.

[0027] The microalgae harvesting method of the present invention is to export the algae liquid from the microalgae photosynthetic reaction system at a certain flow rate of 5L / MIN, and simultaneously export the bittern from the bittern water storage tank at a flow rate of 0.01L / MIN, and the algae liquid and the bittern The mixture flows through a runway pool and is fully mixed, and enters the deep groove at the end of the runway pool, which is the algae liquid to be collected; start the electrocoagulation-air flotation combined microalgae continuous harvesting device of the present invention, and the algae liquid to be collected passes through the algae The liquid inlet 1 enters the electroflocculation air flotation area at a flow rate of 5.01L / MIN. When the liquid level in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com