Binding glue for polyphenyl plate and preparation method of binding glue

A technology of bonding glue and polystyrene board, which is applied in the field of polystyrene board bonding glue and its preparation, can solve the problems affecting the quality and service life of insulation boards, the polystyrene board products have peculiar smell, poor fire resistance, etc., and achieve structural stability , Not easy to age and pulverize, good water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

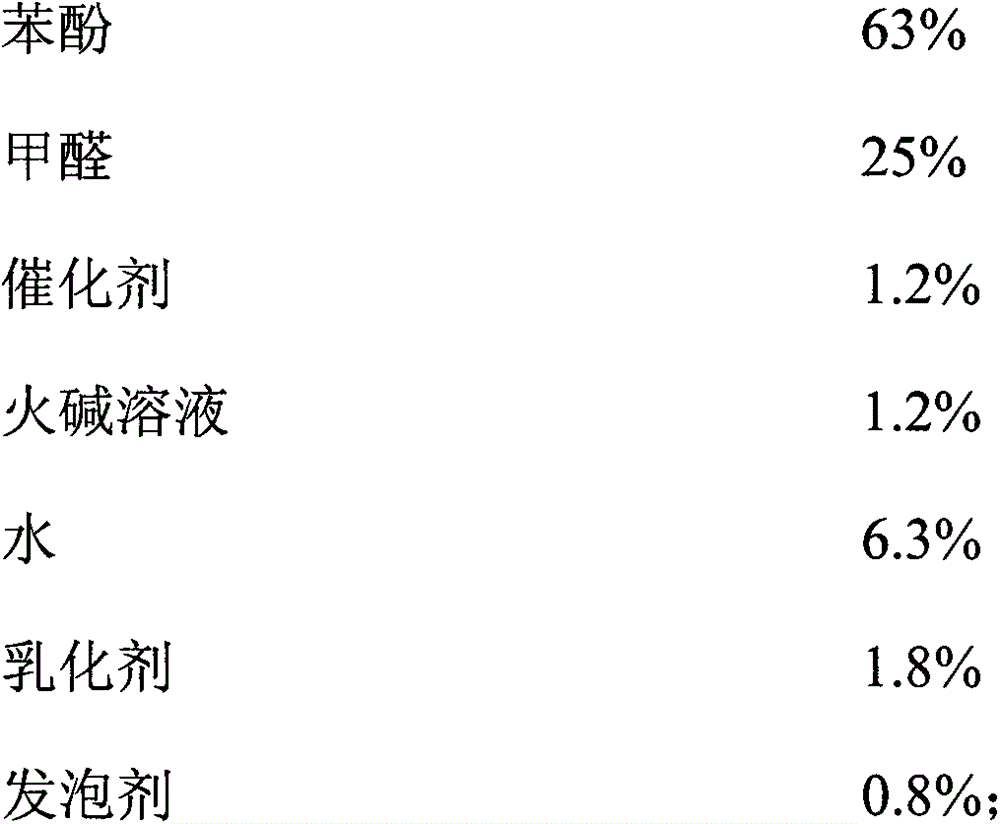

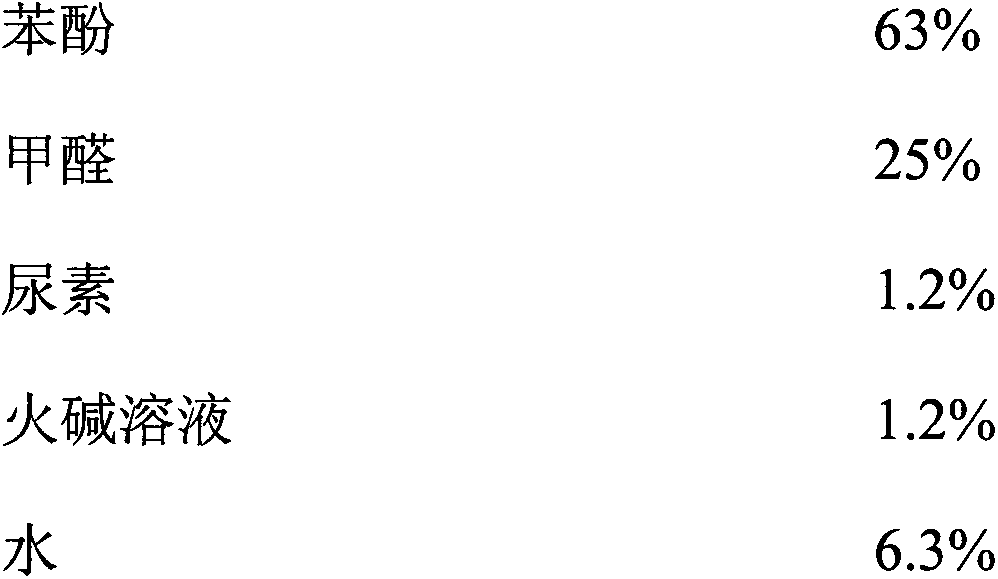

[0024] A kind of adhesive glue for polystyrene board, described adhesive glue is made up of A component and B component, when described adhesive glue is used, the mass ratio range of A component and B component is 9 ~14:1; by mass percentage, the composition and content of component A and component B in the adhesive are as follows:

[0025] A component

[0026]

[0027]

[0028] B component

[0029] Methanol 10%

[0030] p-toluene sulfuric acid 40%

[0031] Phosphoric acid 50%;

[0032] Wherein, the B component is the reactive curing agent of the A component.

[0033] A preparation method for adhesive glue for polystyrene boards, said preparation method includes the preparation methods of component A and component B respectively, wherein the preparation method of component A is as follows: preheating the reactor, waiting for the reactor After the temperature in the reactor reaches 50-60 degrees, add 63% liquid phenol and 1.2% caustic soda solution into the reactor; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com