Nano material compound waste crumb rubber modified asphalt for heavy traffic road and preparation process thereof

A technology of nano-materials and modified asphalt, which is applied in building insulation materials, building components, buildings, etc., can solve the problems of rubber asphalt that are prone to cracking at low temperature, difficult to achieve road use effect, segregation, etc., and achieve anti-ultraviolet aging ability Improved, enhanced storage stability, improved temperature sensitivity effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

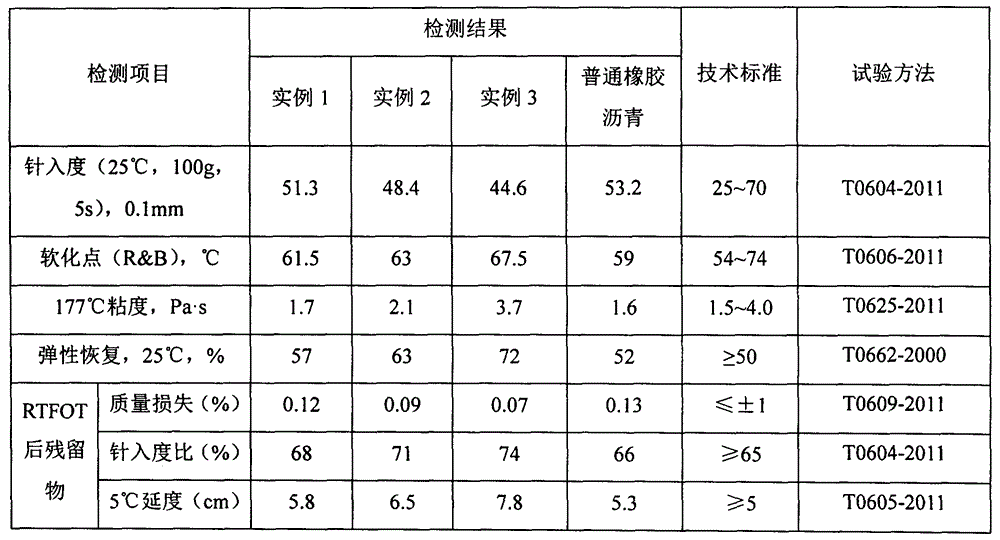

[0023] Example 1: A kind of nano-material composite waste rubber powder modified asphalt, made of the following raw materials in parts by mass:

[0024] Base asphalt 100kg; nano titanium dioxide 0.08kg; waste rubber powder 8kg;

[0025] The preparation method of nano-material composite waste rubber powder modified asphalt is characterized in that it comprises the following steps:

[0026] 1), take each component by mass ratio;

[0027] 2) Heat the base asphalt to 160°C, slowly add the weighed nano-titanium dioxide, and shear at high speed for 30 minutes to make it evenly mixed;

[0028] 3) Heat the asphalt mixture in step 2 to 205°C, slowly add the weighed waste rubber powder, and shear at high speed for 120 minutes to prepare nano-material compound waste rubber powder modified asphalt.

Embodiment 2

[0029] Embodiment 2: A nano-material composite waste rubber powder modified asphalt is made of the following raw materials in parts by mass:

[0030] 100 parts of base asphalt; 0.15 parts of nano-titanium dioxide; 15 parts of waste rubber powder;

[0031] The preparation method is the same as in Example 1.

Embodiment 3

[0032] Embodiment 3: A nano-material compound waste rubber powder modified asphalt, made of the following raw materials in parts by mass:

[0033] 100 parts of base asphalt; 0.3 parts of nano-titanium dioxide; 30 parts of waste rubber powder;

[0034] The preparation method is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| penetration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com